Laminated adhesive and preparation method thereof

A technology of adhesives and solvents, applied in the direction of adhesives, polymer adhesive additives, adhesive additives, etc., can solve the problems of poor ink layer affinity, difficult coating, environmental pollution, etc., and achieve improved adhesion, Ease of application and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

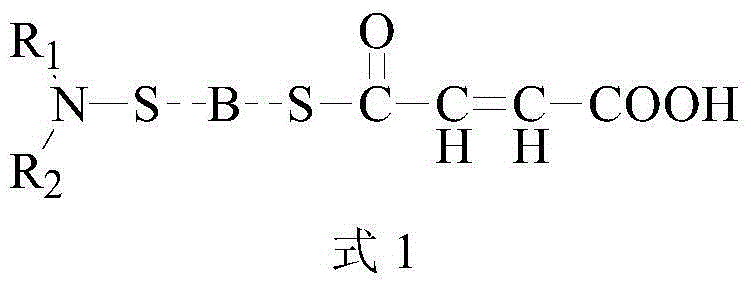

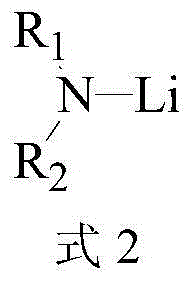

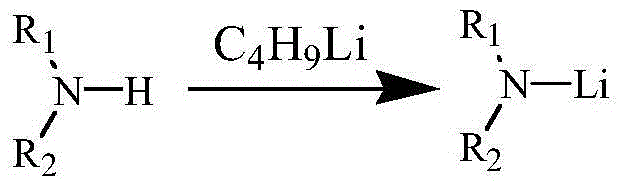

Method used

Image

Examples

Embodiment 1

[0037] Compound the modified SBS in Table 1 according to the laminating adhesive formula in Table 2, add modified SBS, tackifying resin and organic solvent into the container, and after fully dissolving, add emulsifier and deionized water to Cut emulsifier for emulsification to obtain water-emulsion laminating adhesive. The properties of the obtained water-emulsion laminating adhesive are shown in Table 3 below.

[0038] Table 1 Characteristic parameters of modified SBS

[0039] Sample serial number

corresponding sample

1#

S / B=3 / 7, Mn=89,000

2#

S / B=3 / 7, Mn=108,000

3#

S / B=3 / 7, Mn=127,000

4#

S / B=2 / 8, Mn=82,000

5#

S / B=2 / 8, Mn=104,000

6#

S / B=4 / 6, Mn=83,000

7#

S / B=4 / 6, Mn=105,000

[0040] Table 2 Formula composition of modified SBS water-emulsion laminating adhesive

[0041] components

parts by weight

Modified SBS

2 copies

Terpene resin

5 copies

Rosi...

Embodiment 2

[0046] Except that modified SBS adopts 5# of Table 1 and emulsifier adopts anionic and nonionic emulsifier combination (SDBS+OP-10), others are the same as Example 1. The obtained laminating adhesive emulsion is a white uniform emulsion with a pH of 6.7, a viscosity of 265 at 25° C., a peel strength of 25, and the coating film has no foaming and a smooth plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com