An operation panel for a dyeing machine

An operation panel and dyeing machine technology, which is applied in the processing of textile materials, accessories of textile processing machines, textiles and paper making, etc., can solve problems such as potential safety hazards, and achieve the effect of simple and easy-to-understand operation, reasonable structure, and safe operation and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

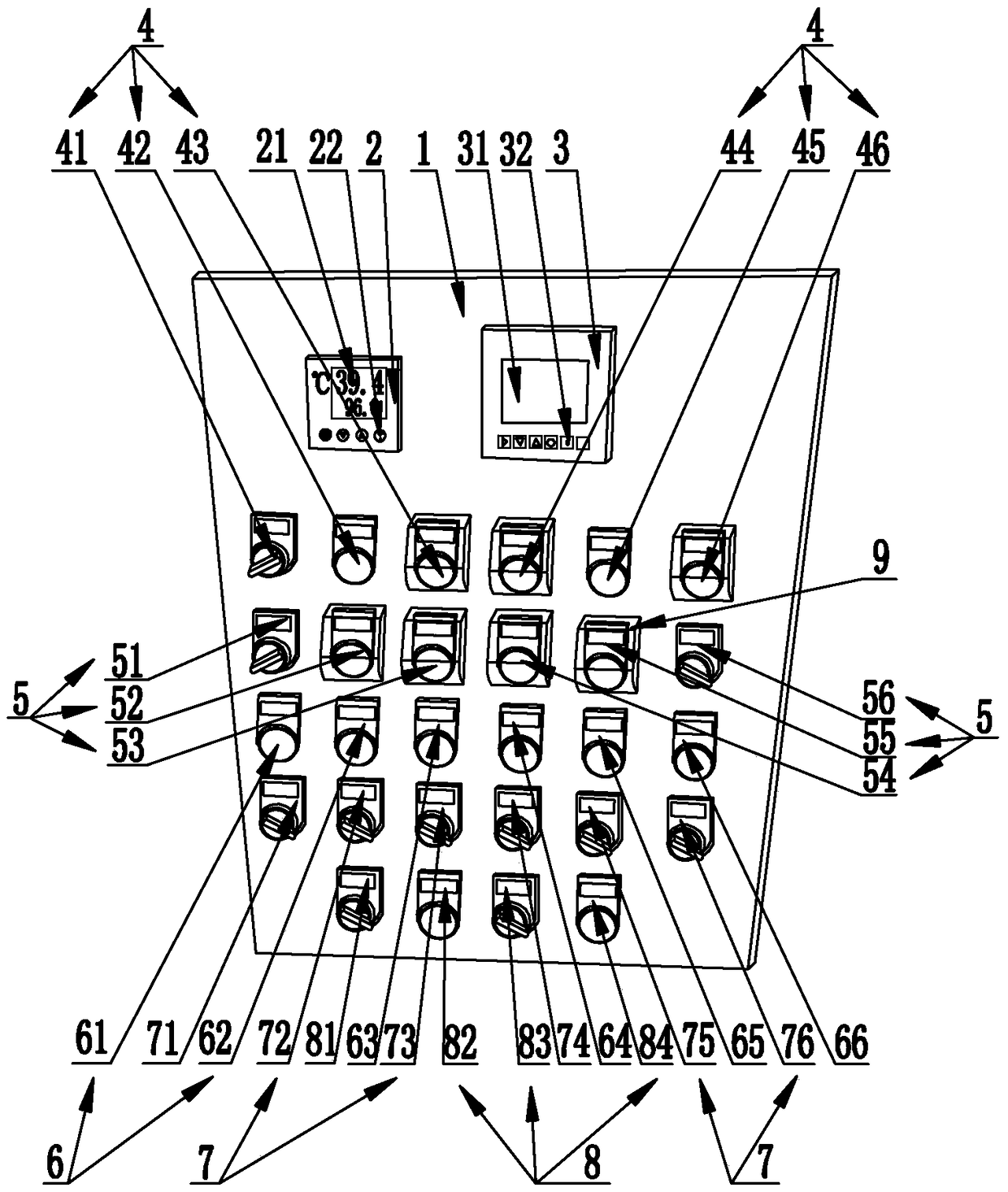

[0031] Such as figure 1 As shown, an operation panel for a dyeing machine includes a board body 1, a temperature control panel 2 is installed on the left side of the upper part of the board body 1, and a temperature display screen 21 and a temperature control panel 2 are installed on the temperature control panel 2. Buttons 22; the right side of the top of the board body 1 is equipped with a program setting panel 3, and the program setting panel 3 is equipped with a program display screen 31 and a program selection button 32; the middle and bottom of the board body 1 are horizontally provided with Five rows of components, the five rows of components from top to bottom are the first row 4, the second row 5, the third row 6, the fourth row 7 and the fifth row 8, the first row 4 to the fifth row Four rows of 7 components are arranged in an array, and the first row 4 on the board body 1 is sequentially installed with a power switch 41, a power indicator light 42, a reverse cycle 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com