Pumping equipment for borehole pumping tests

A pumping test and equipment technology, which is applied to mechanical equipment, components of pumping devices for elastic fluids, pump components, etc., can solve problems such as small head, and achieve the effects of improving service life, driving force and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

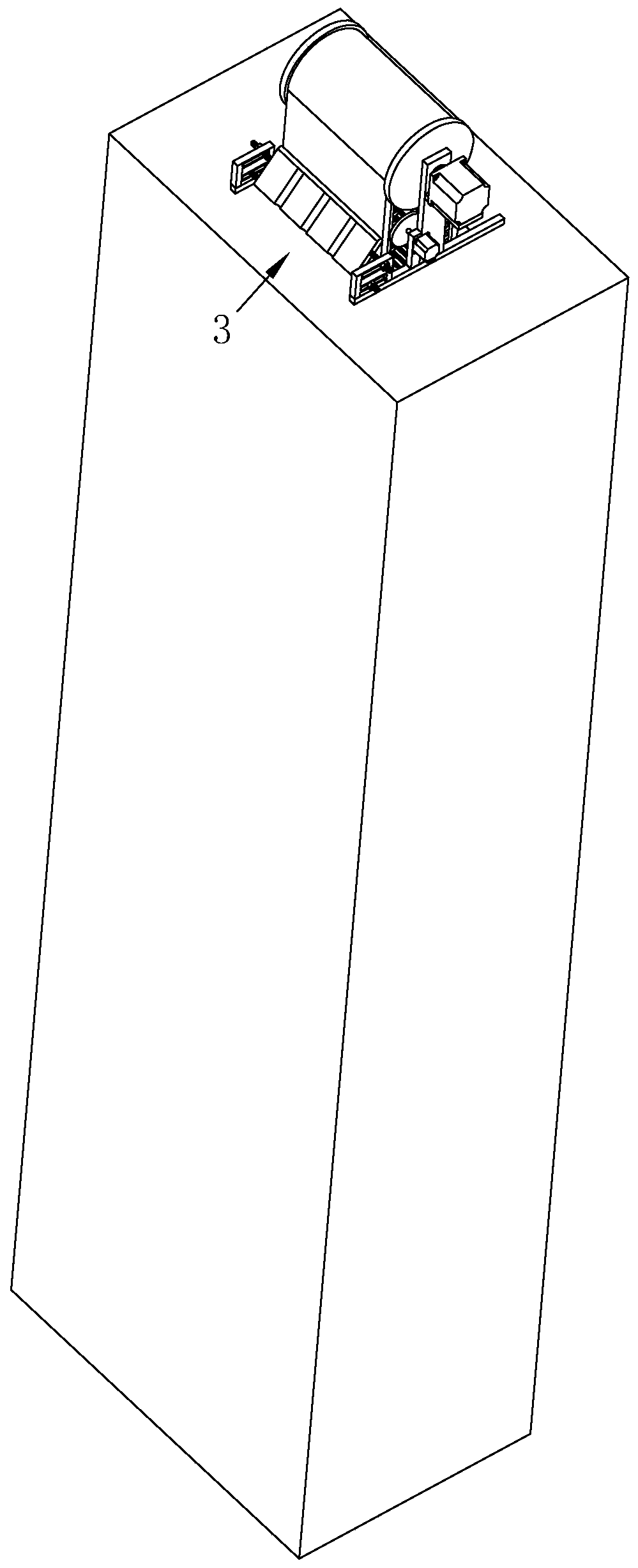

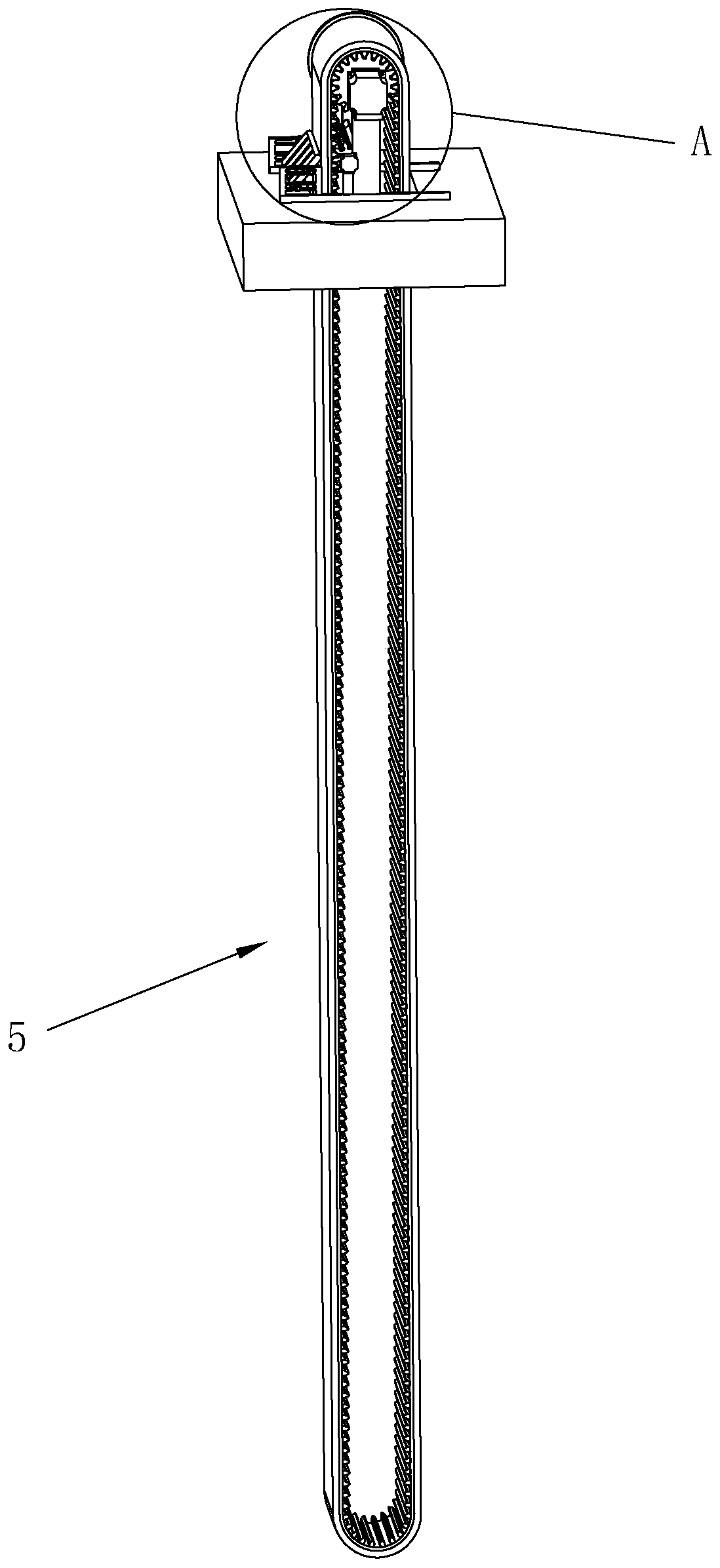

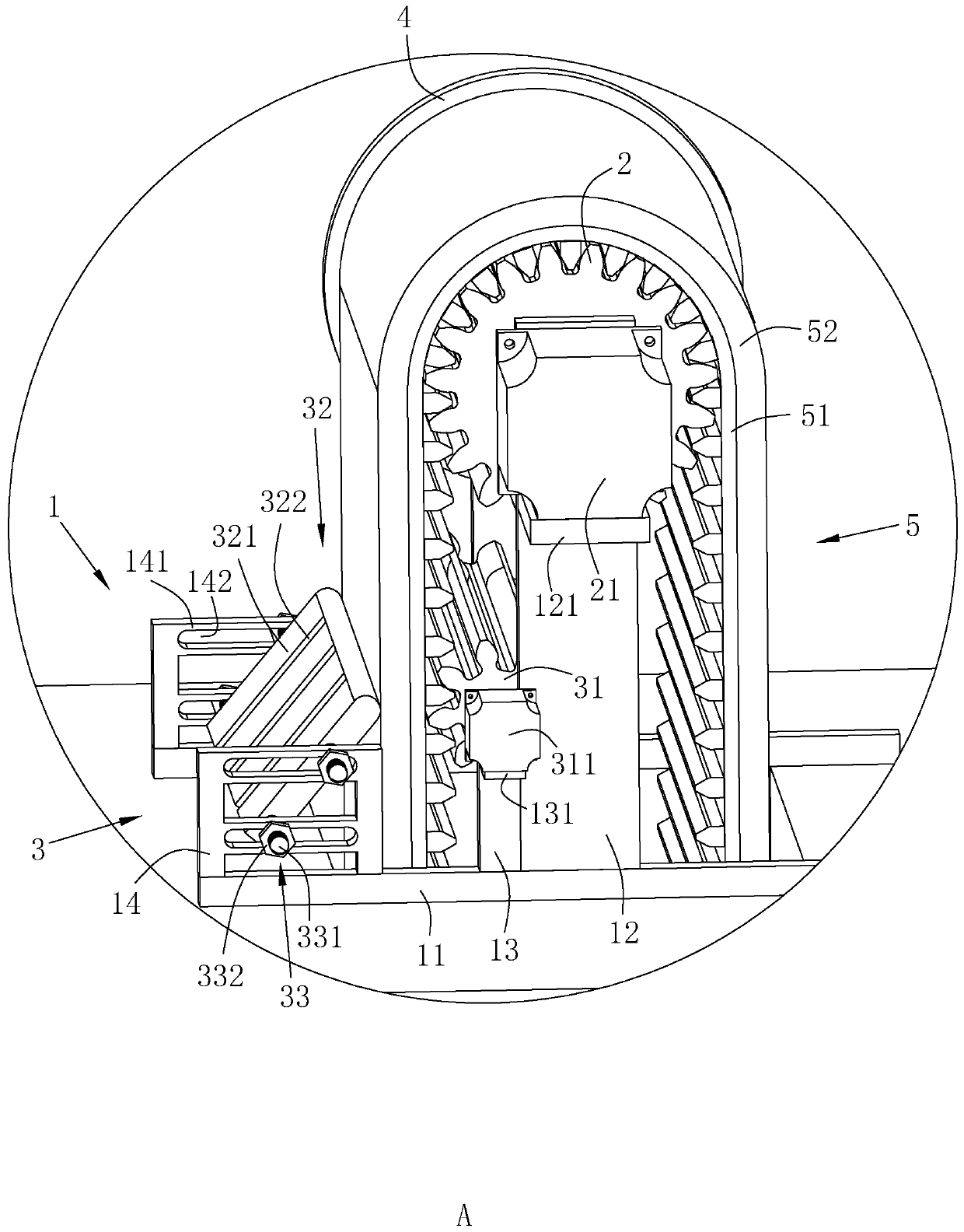

[0044] A kind of pumping equipment for borehole pumping test, refer to figure 1 , figure 2 as well as image 3 , including a mounting frame 1, the mounting frame 1 is provided with a main rotating part 2 rotating around the horizontal direction, the main rotating part 2 is wrapped with a conveyor belt 5, and the conveyor belt 5 includes a waterproof layer 51 abutting on the main rotating part 2 and a waterproof The layer 51 is away from the water-absorbing layer 52 on the side of the main rotating part 2 , and the mounting frame 1 is provided with an extruding assembly 3 for extruding the conveyor belt 5 .

[0045] refer to image 3The installation frame 1 includes two support bars 11 horizontally abutting on the ground and parallel to each other. The support bars 11 are fixed with a main fixed plate 12 extending vertically upwards. The main rotating part 2 is a gear, and the main rotating part 2 is fixed with a The main rotating shaft of the main rotating part 2 extends a...

Embodiment 2

[0086] The difference from Example 1 is that,

[0087] The water-absorbing layer 52 includes the following components in parts by mass:

[0088] 100 parts of polyurethane; 7 parts of foaming agent; 6 parts of carbon fiber and 3 parts of ceramic powder.

[0089] Polyurethane is made by reacting PEG, MDI and BDO, and the molecular weight of PEG is 4000.

Embodiment 3

[0091] The difference from Example 1 is that,

[0092] The water-absorbing layer 52 includes the following components in parts by mass:

[0093] 100 parts of polyurethane; 9 parts of foaming agent; 8 parts of carbon fiber and 4 parts of ceramic powder.

[0094] Polyurethane is made by reacting PEG, MDI and BDO, and the molecular weight of PEG is 4000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com