Prestressed ironing plate

A screed and prestressing technology, which is applied in the field of pavement operation engineering, can solve the problems of affecting the quality of paving pavement operations, difficult processing and installation, and increased thermal deformation at both ends of the screed, and achieves a simple fixing method and low cost. Inexpensive, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below through specific examples.

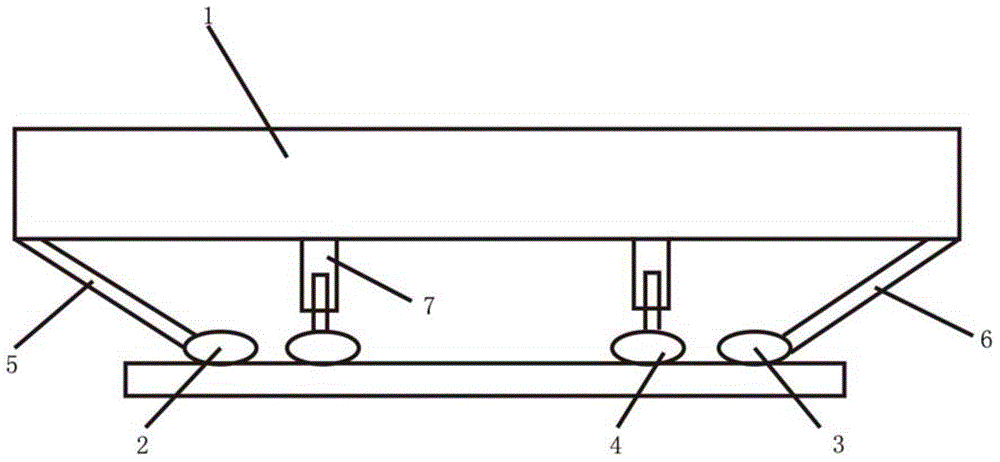

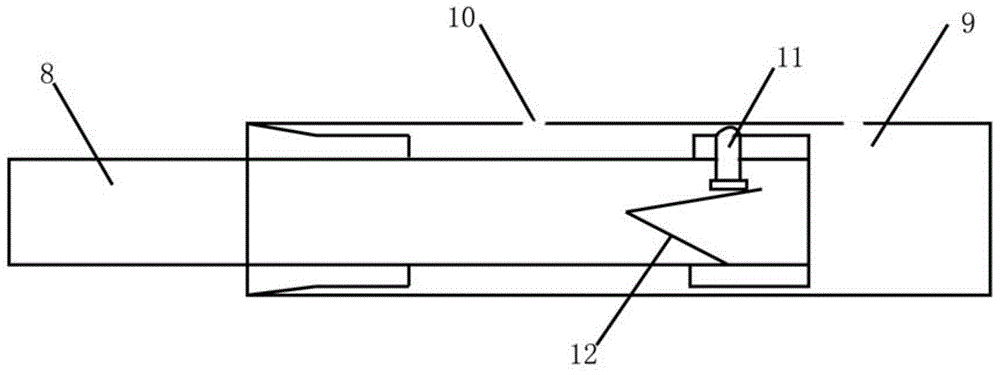

[0015] Such as figure 1 and figure 2 As shown, among them, 1 is the screed main body, 2 is the first screed oil cylinder, 3 is the second screed oil cylinder, 4 is the third screed oil cylinder, 5 is the left support rod, 6 is the right support rod, 7 8 is the inner tube of the left support rod, 9 is the outer tube of the left support rod, 10 is the positioning hole of the left support rod, 11 is the button of the left support rod, and 12 is the elastic device of the left support rod.

[0016] The prestressed screed includes a screed main body 1, a first screed cylinder 2, a second screed cylinder 3 and a third screed cylinder 4. The left side of the screed main body 1 is connected to the first screed cylinder through the left support rod 5 2 connected, the right side of the screed main body 1 is connected with the second screed cylinder 3 through the right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com