Automatic cleaning device for ditch rubbish

An automatic cleaning and ditch technology, applied in water supply devices, waterway systems, buildings, etc., can solve problems such as low work efficiency, affect production process, and affect progress, and achieve the effect of simple structure, improved work efficiency, and guaranteed production progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

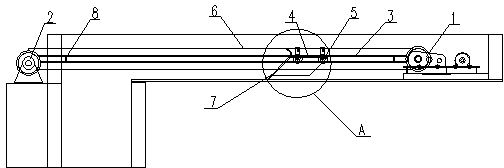

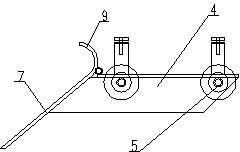

[0014] An automatic cleaning device for ditch garbage, comprising a hoist 1 installed at the right end of the ditch and a pulley 2 installed outside the left end of the ditch, a grooved guide rail 3 is installed on the upper end of the ditch wall inside the ditch, and the grooved guide rail 3 is equipped with a walking The trolley 4, the lower end of the trolley 4 is provided with a roller 5 placed on the grooved guide rail 3, the rear end of the trolley 4 is connected to one end of the wire rope 6, and the other end of the rope 6 bypasses the hoist 1 and the pulley 2 and is connected to the front end of the trolley 4, and the trolley 4 The front end is equipped with pusher plate 7.

[0015] The front and rear ends of the water ditch of the present invention are respectively provided with limit switches 8 to control the positive and negative rotation of the winch 1 to realize the walking trolley 4 to move back and forth in the water ditch.

[0016] The distance between the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com