LED headlamp

A technology of LED wicks and headlamps, applied in lighting devices, non-electric lighting devices, fixed lighting devices, etc., can solve the problems of increasing the power of bulbs, changing bulbs from time to time, and waste of heat energy, so as to prolong the service life and reduce waste , no noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

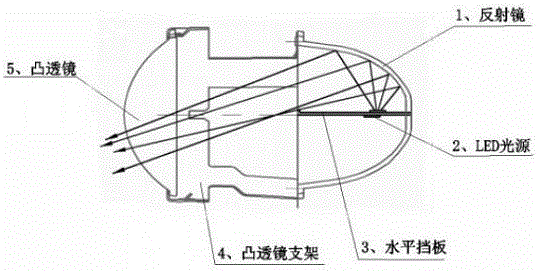

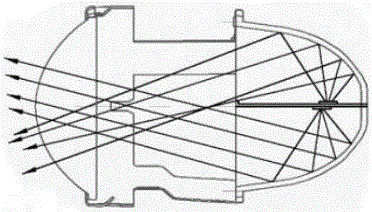

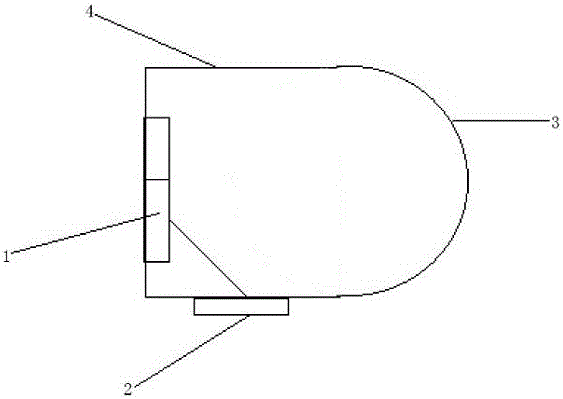

[0019] image 3 Shown is a schematic diagram of the structure of the LED headlight, figure 1 Shown is a structural schematic diagram of LED wick 1 with LED low-beam optical reflection lines, such as figure 1 , image 3 As shown, an LED headlamp is mainly composed of an LED wick 1, an LED driver board 2, a lamp glass 3, and a lamp housing 4 sealed and assembled. It is characterized in that the LED wick 1 is mainly composed of a convex lens (1), a lens Bracket (2), mirror (3), horizontal light barrier (4), and LED light source (5) are sealed and assembled, characterized in that: the end of the horizontal light barrier (4) near the convex lens (1) is manufactured to The shape of the light-dark cut-off line required by the light, the horizontal light barrier (4) divides the reflector (3) into upper and lower parts, the upper part is the low-beam light distribution reflector,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com