A kind of solar water heater heat collecting tube and manufacturing method thereof

A technology of a solar water heater and a manufacturing method, applied in the field of solar energy, can solve the problems of low heat absorption efficiency, unable to meet people's water demand, etc., and achieve the effects of good film performance, good biocompatibility, and good light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

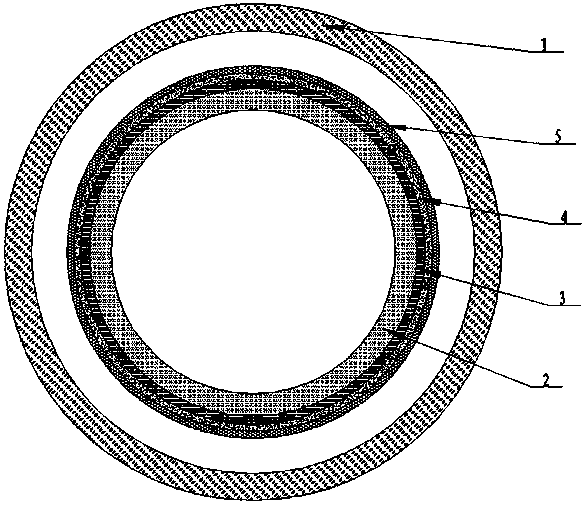

[0026] A solar water heater collector tube, such as figure 1 As shown, it includes an outer tube 1 (made of glass) and an inner tube 2, a vacuum layer is formed between the outer tube 1 and the inner tube 2, and the inner tube 2 is a sleeve tube pressed from nanodiamondene, and the inner tube 2 The outer surface is provided with an infrared reflective layer 3, an absorbing layer 4 and a light-transmitting protective layer 5 in sequence from the inside to the outside, the thickness of the infrared reflecting layer 3 is 100 nm, the thickness of the absorbing layer 4 is 500 nm, and the light-transmitting protective layer 5 The thickness of the light-transmitting protective layer 5 is 60 nm.

[0027] The manufacturing method of the above-mentioned heat collecting tube comprises the following steps:

[0028] 1) Production of the inner tube 2: After mixing the nanodiamondene with the binder mainly composed of epoxy resin and heat-resistant glue at a mass ratio of 5:5, press molding...

Embodiment 2

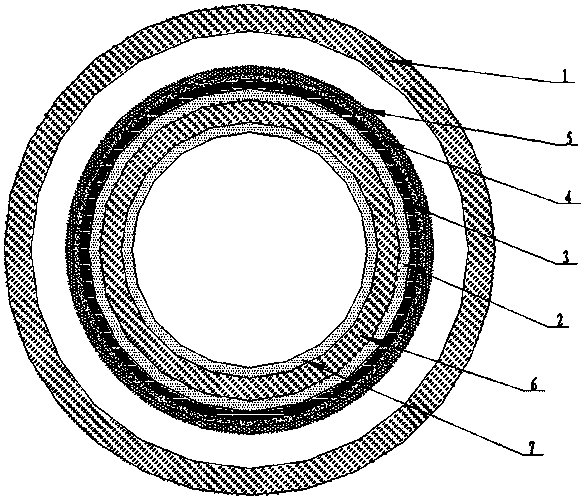

[0033] A solar water heater collector tube, such as figure 2 As shown, it includes an outer tube 1 (made of glass) and an inner tube 2, a vacuum layer is formed between the outer tube 1 and the inner tube 2, and the inner tube 2 is a sleeve tube pressed from nanodiamondene, and the inner tube 2 is also provided with a glass tube 6, the inner surface of the glass tube 6 is coated with a nanodiamondene layer 7, and the outer surface of the inner tube 2 is sequentially provided with an infrared reflection layer 3, an absorbing layer 4 and a light-transmitting protective layer from the inside to the outside. 5. The thickness of the infrared reflection layer 3 is 300 nm, the thickness of the absorption layer 4 is 1 μm, and the thickness of the light-transmitting protective layer 5 is 30 nm.

[0034] The manufacturing method of the above-mentioned heat collecting tube comprises the following steps:

[0035] 1) First coat the inner surface of the glass tube 6 with a nanodiamondene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com