Cabin-level axial double-table synchronous vibration test system

A test system and synchronous vibration technology, applied in the field of test systems, can solve the problems of higher center of mass of the test piece, longer test preparation period, and increased shaking table, so as to avoid the cantilever effect, improve safety and reliability, and improve the real degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

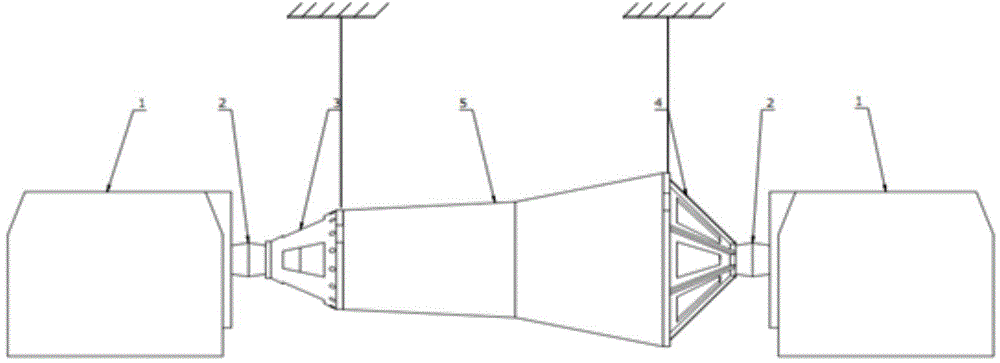

[0012] as attached figure 1 As shown, a cabin-level axial dual-table synchronous vibration test system includes a vibration table 1, a high-frequency hydraulic ball head 2, a tail tooling 3, and a head tooling 4, of which there are two vibration tables 1, which are installed in the entire test At both ends of the system, the output end of each vibrating table 1 is fixedly connected with the high-frequency hydraulic ball head 2, wherein the vibrating table 1 set at the front end is fixedly connected with the head tooling 4 through the high-frequency hydraulic ball head 2, and the one set at the rear end The vibration table 1 is fixedly connected with the tail tooling 3 through the high-frequency hydraulic ball head 2, and the tested specimen 5 is installed between the head tooling 4 and the tail tooling 3.

[0013] The head frock 4 and the tail frock 3 are suspended by the suspension system respectively. The suspension system can be any suspension system in the prior art. Thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com