Rolling bearing dynamic performance testing machine and general frame thereof

A technology of dynamic performance and rolling bearings, applied in the direction of mechanical bearing testing, etc., can solve the problems of poor versatility and achieve good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

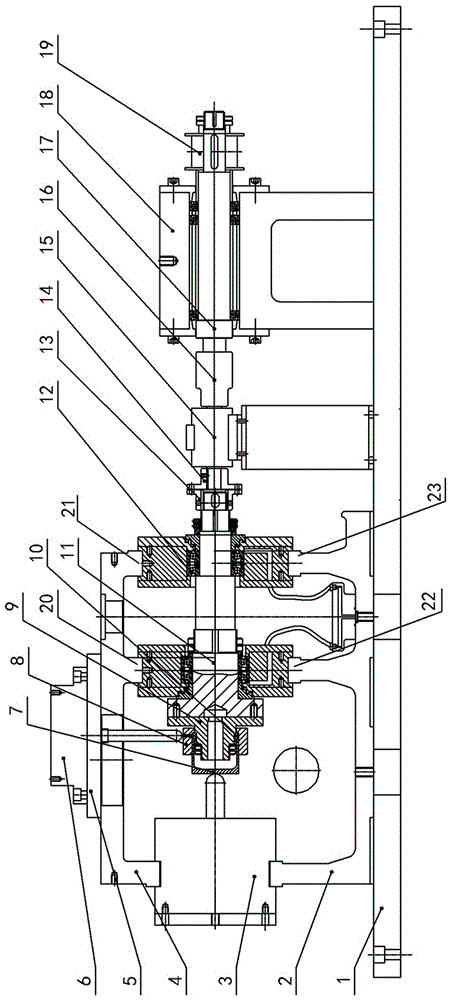

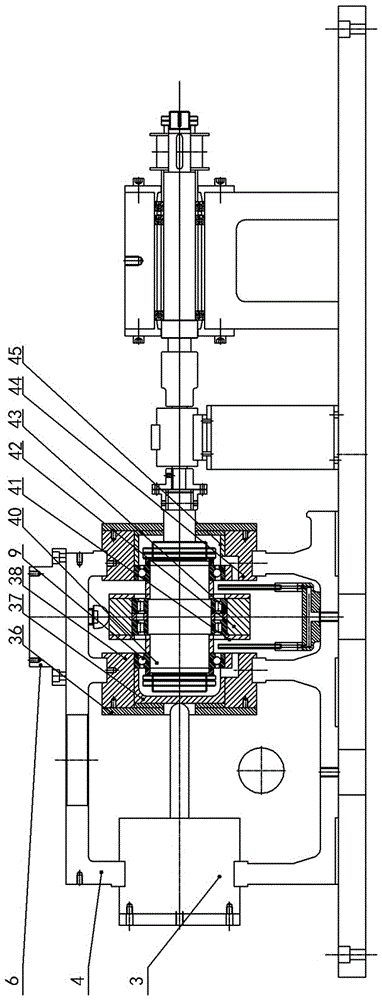

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] The specific embodiment of rolling bearing dynamic performance testing machine provided by the present invention, as figure 1 and figure 2 As shown, the testing machine in this embodiment includes a frame, and the frame includes a base 1, and the base 1 is provided with an upper frame body 4 and a lower frame body 2, and the upper frame body and the lower frame body are detachably fastened and assembled together. The frame at the place is a universal frame, which can be installed with cantilever shafting or bridge shafting according to actual test requirements. There are also sets on the frame for installing radial shafts at different positions corresponding to different shaftings. Radial loading position to the loading device.

[0024]Specifically, the upper frame body 4 is provided with a left side upper pressing part 20 and a right side uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com