Camera lens and electronic device

A camera lens and lens technology, which is applied in the field of camera lenses, can solve the problems of increasing the height of the camera lens and not being able to satisfy the thinning and thinning of personal electronic products, and achieve the effect of reducing the total length and satisfying miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

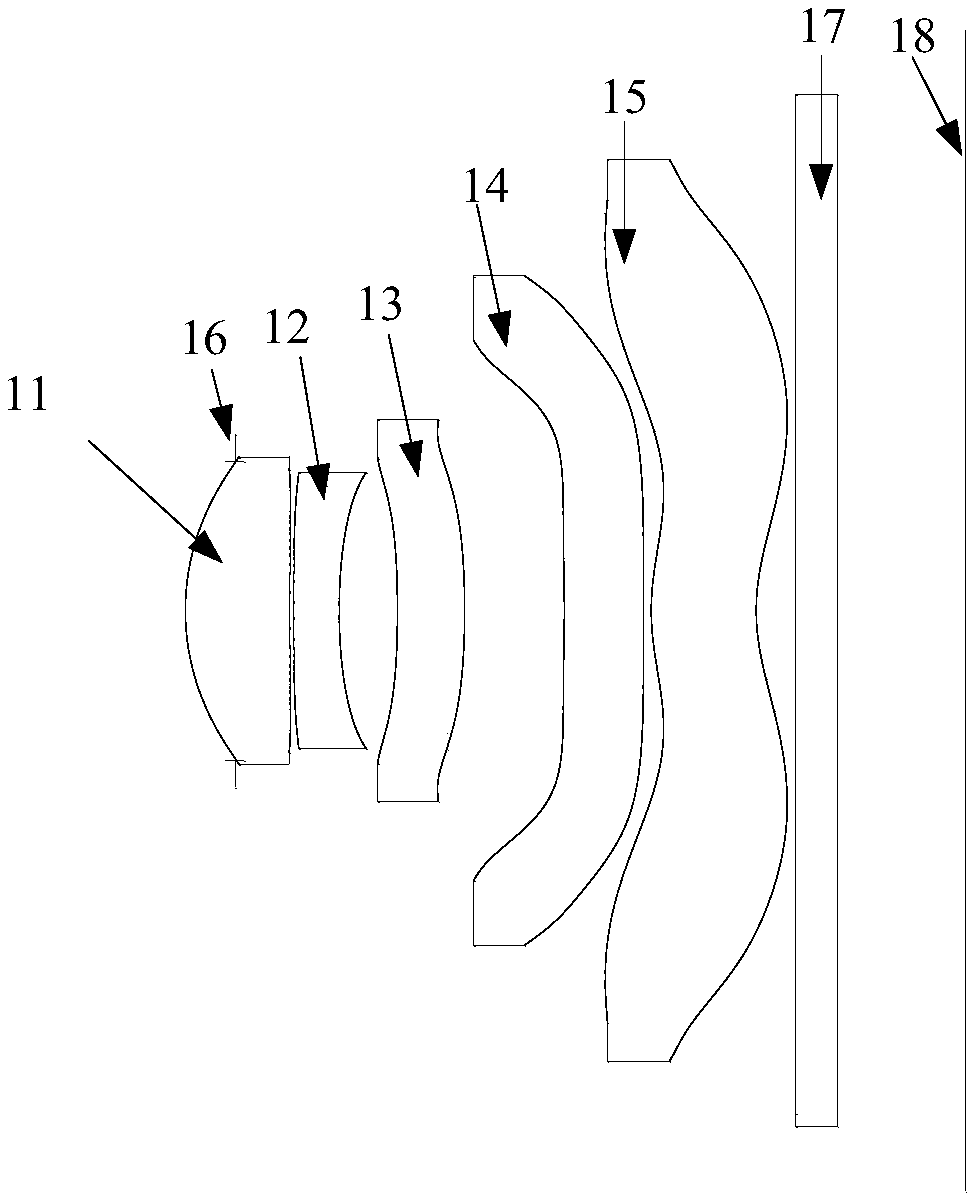

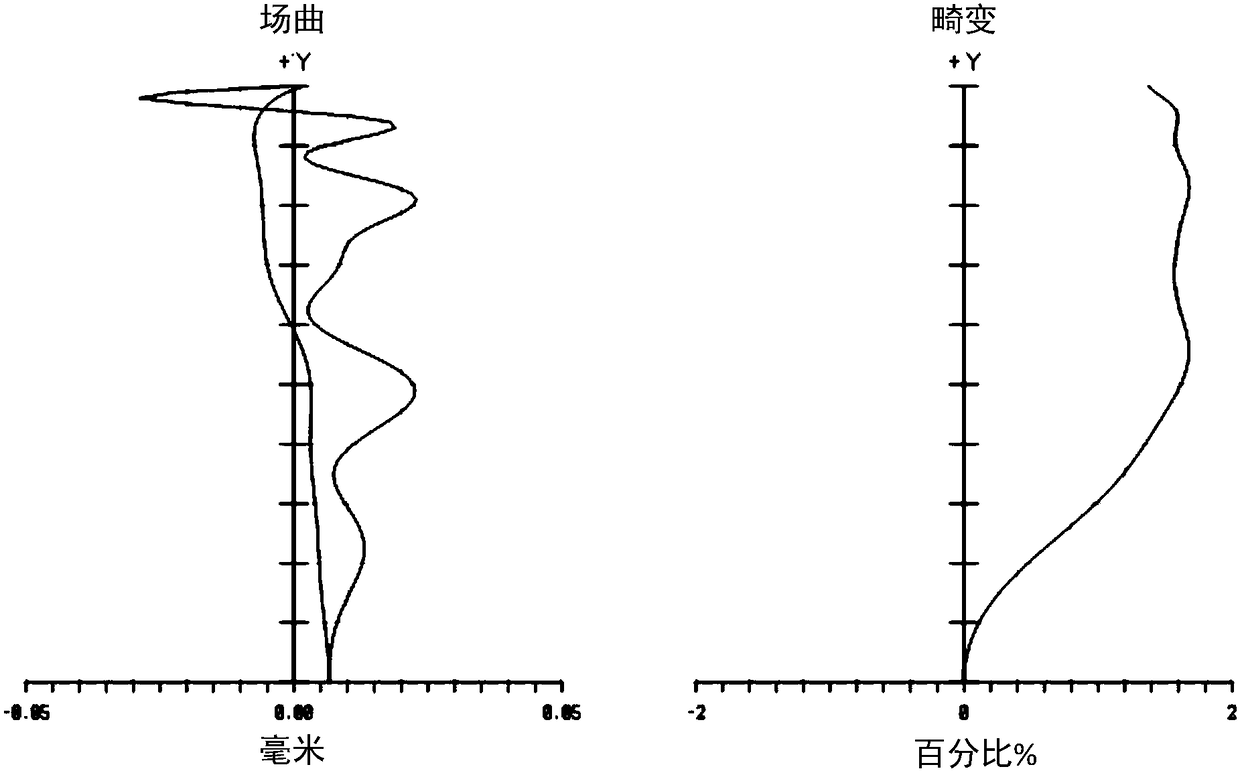

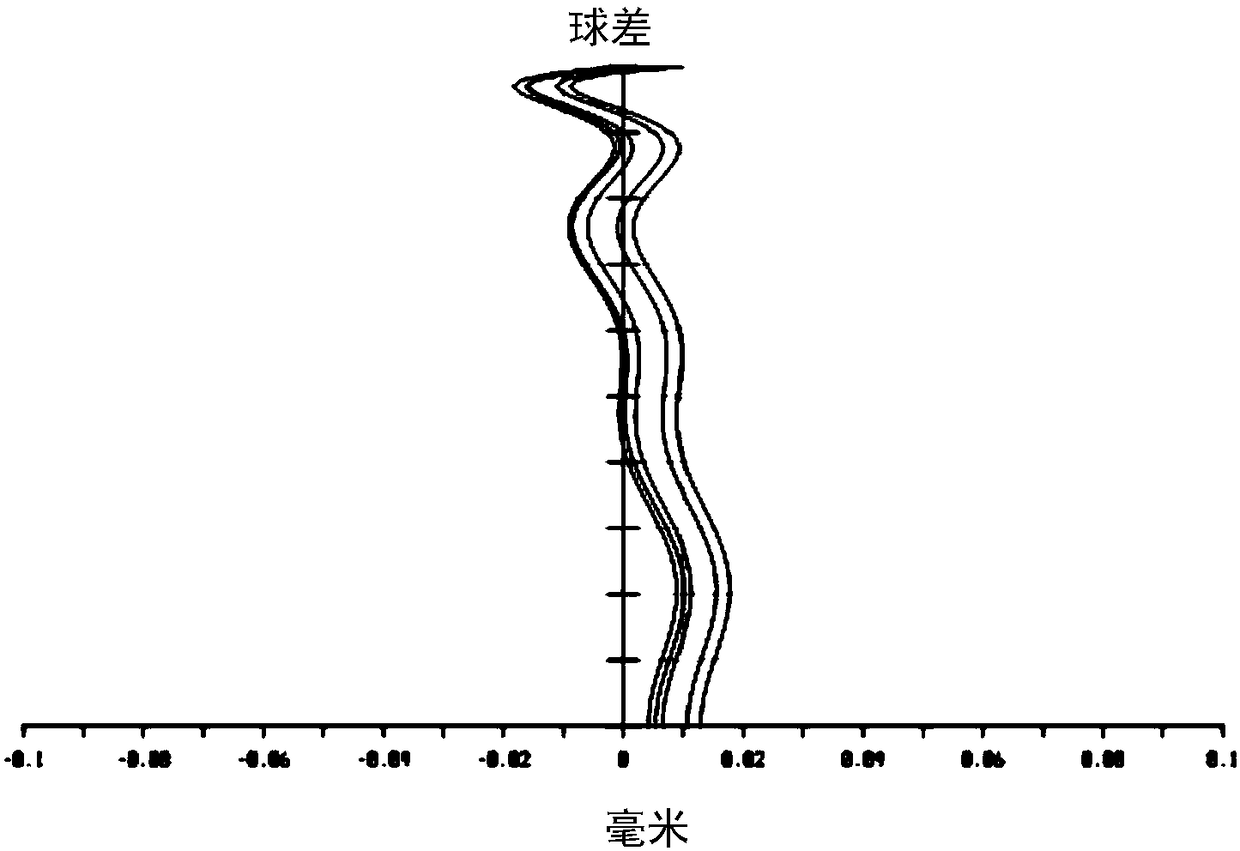

[0083] In this embodiment, the structure of the imaging lens including the first lens 11 to the fifth lens 15, the aperture 16 and the filter 17 is as follows: figure 1 As shown, the field curvature and distortion curves are shown as figure 2 As shown, the spherical aberration curve is shown as image 3 shown.

[0084] Wherein, the specific parameters of the first lens 11 to the fifth lens 15, the aperture 16 and the optical filter 17 refer to Table 1-1, and the specific parameters of the aspheric surfaces of the first lens 11 to the fifth lens 15 are shown in Table 1-2 . In Table 1-1 and Table 1-2, Surface 2 represents the object-side surface of the first lens 11, Surface 3 represents the image-side surface of the first lens 11, Surface 4 represents the object-side surface of the second lens 12, and Surface 5 represents the object-side surface of the first lens 11. The image-side surface of the second lens 12, the object-side surface of the third lens 13 in surface 6, the...

Embodiment approach 2

[0106] In this embodiment, the structure of the imaging lens including the first lens 11 to the fifth lens 15, the aperture 16 and the filter 17 is as follows: Figure 4 As shown, the field curvature and distortion curves are shown as Figure 5 As shown, the spherical aberration curve is shown as Image 6 shown. The specific parameters of the first lens 11 to the fifth lens 15 , the aperture 16 and the filter 17 refer to Table 2-1, and the specific parameters of the aspheric surfaces of the first lens 11 to the fifth lens 15 are shown in Table 2-2.

[0107] table 2-1

[0108]

[0109]

[0110] Table 2-2

[0111]

[0112] Specifically, in this embodiment, TTL / I mgh =1.34, satisfying 1.3mgh <1.5 relational formula;

[0113] |f / f 2 |=0.73, satisfying 0.72 |<0.8 relational expression;

[0114] |f / f 3 |+|f / f 4 |=0.71, satisfying 0.43 |+|f / f 4 |<0.75 relational expression;

[0115] R 10 / f=26.30, satisfying 3.210 The relational expression of / f<30;

[0116] (R ...

Embodiment approach 3

[0128] In this embodiment, the structure of the imaging lens including the first lens 11 to the fifth lens 15, the aperture 16 and the filter 17 is as follows: Figure 7 As shown, the field curvature and distortion curves are shown as Figure 8 As shown, the spherical aberration curve is shown as Figure 9 shown. The specific parameters of the first lens 11 to the fifth lens 15 , the aperture 16 and the filter 17 refer to Table 3-1, and the specific parameters of the aspheric surfaces of the first lens 11 to the fifth lens 15 are shown in Table 3-2.

[0129] Table 3-1

[0130]

[0131] Table 3-2

[0132]

[0133]

[0134] Specifically, in this embodiment, TTL / I mgh =1.36, satisfying 1.3mgh <1.5 relational formula;

[0135] |f / f 2 |=0.74, satisfying 0.72 |<0.8 relational expression;

[0136] |f / f 3 |+|f / f 4 |=0.44, satisfying 0.43 |+|f / f 4 |<0.75 relational expression;

[0137] R 10 / f=13.65, satisfying 3.210 The relational expression of / f<30;

[0138] (R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com