Integrated high-pressure gas pressure reduction module

A high-pressure gas, integrated technology, applied in the direction of fluid pressure control, instruments, control/regulation systems, etc., can solve the problem that the air tightness of the high-pressure gas system cannot be further improved, the inlet pressure gauge and the outlet pressure gauge cannot be installed, and the impact on the high pressure The problems such as the normal operation of the gas system can be solved to achieve the effect of improving construction efficiency and quality, saving installation space, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

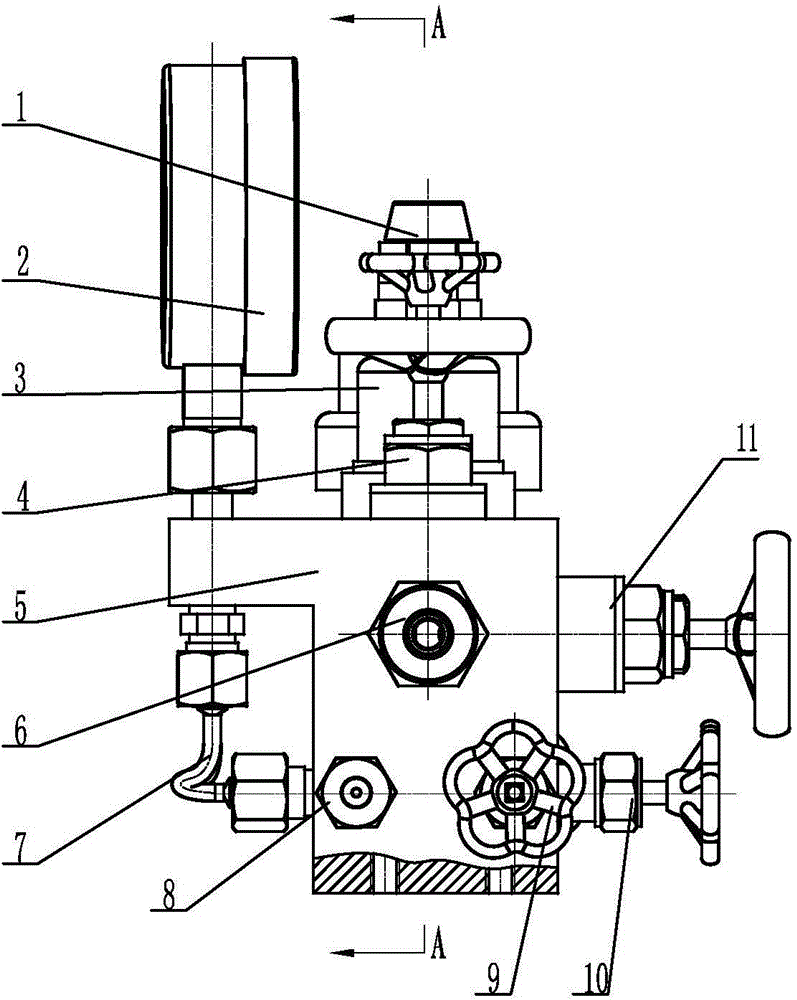

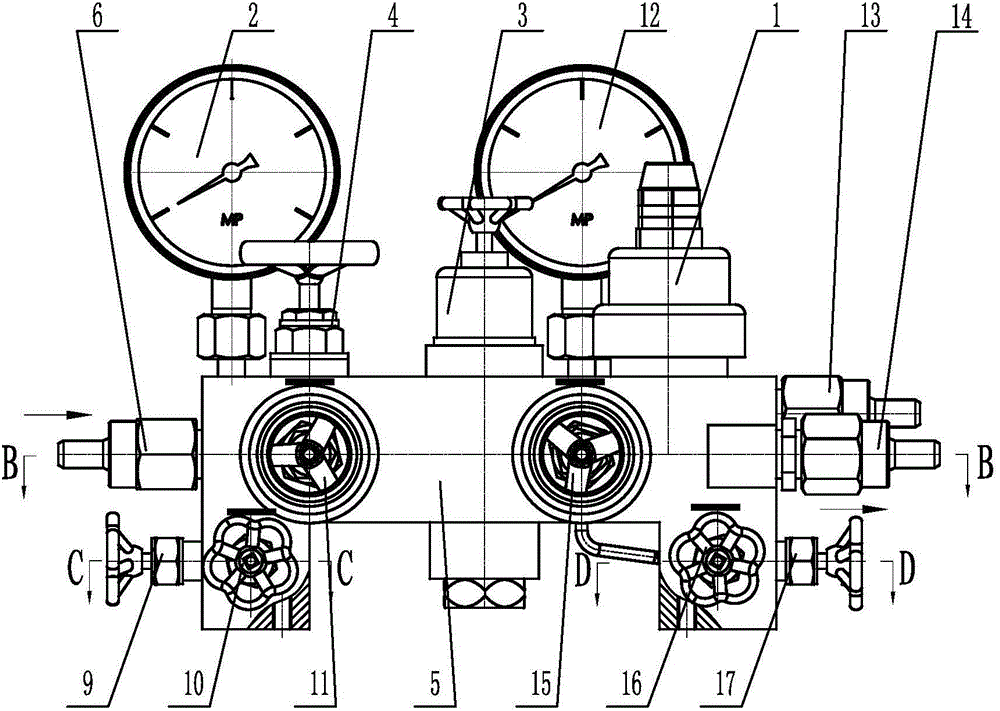

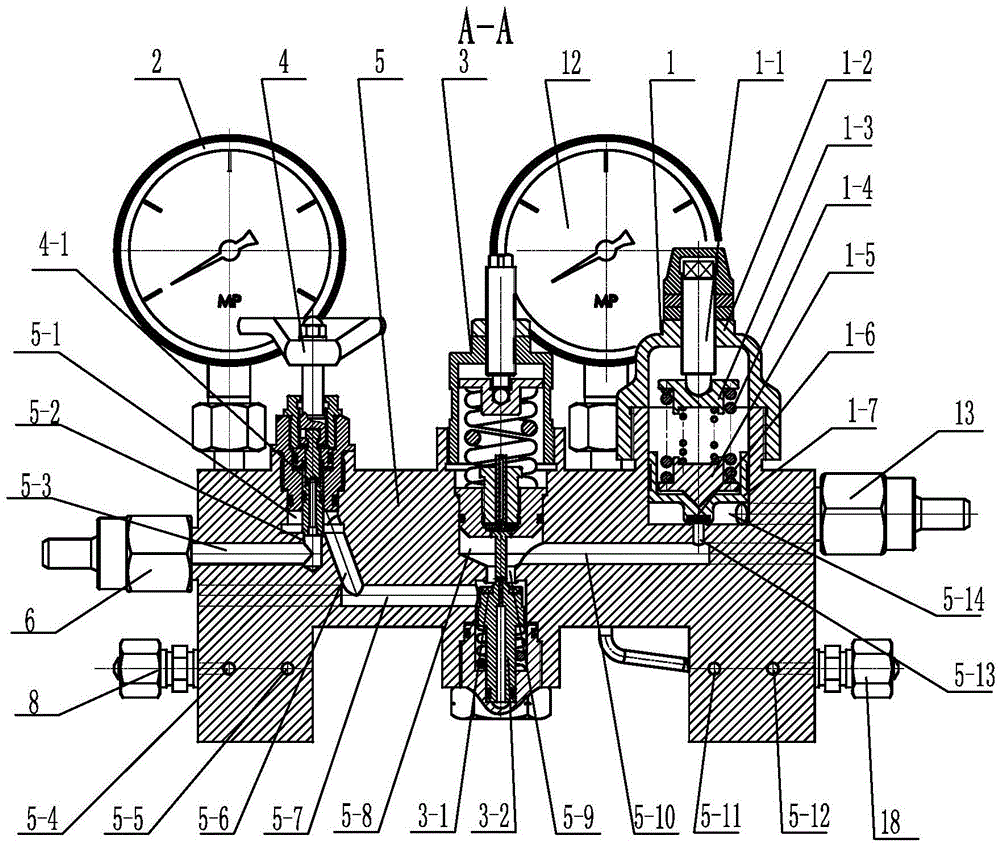

[0031] See Figure 1-8 As shown, the high-pressure gas integrated decompression module of the present invention includes a valve body 5, an intake pressure gauge 2, a front cut-off valve 4, a pressure-reducing valve 3, a safety valve 1, a bypass throttle valve 11 and a rear cut-off valve 15 And outlet pressure gauge 12.

[0032] See Figure 1~4As shown, the valve body 5 of the present invention is provided with an inlet flow passage 5-3, a decompression flow passage 5-10 and an outlet flow passage 5-16, and the inlet flow passage 5-3 passes through the first intermediate flow passage 5-7 and the decompression flow passage. The pressure flow channel 5-10 communicates, and the inlet flow channel 5-3 also communicates with the outlet flow channel 5-16 through the bypass flow channel 5-18, and the decompression flow channel 5-10 passes through the back cut-off valve flow channel 5-19 and The outlet flow passages 5-16 are connected, so the high-pressure gas of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com