Automatic defoaming agent adding device for dispersing conductive slurry of carbon nano-tube

A technology of conductive paste and carbon nanotubes, applied in non-electric variable control, instruments, control/regulation systems, etc., can solve the problems of volatile defoamer, uncontrollable amount of defoamer added, poor defoaming effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present application will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

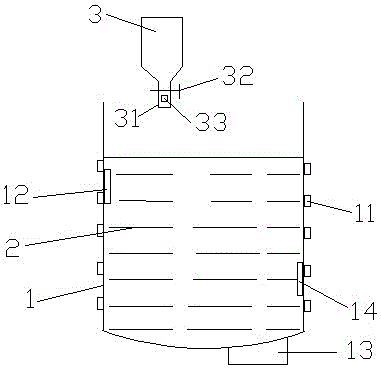

[0030] Such as figure 1 Shown, a kind of defoamer automatic adding device for carbon nanotube conductive slurry dispersing, wherein has column grinding bucket 1, circulating water pipe 11, liquid level sensor 12, controller 13, temperature sensor 14, carbon nanotube conductive slurry 2. Defoamer storage tank 3, liquid outlet 31, solenoid valve 32, flow sensor 33 and other main technical features.

[0031] An automatic defoamer adding device for dispersing carbon nanotube conductive paste comprises a vertical grinding barrel, carbon nanotube conductive paste and defoamer storage tank.

[0032] There is a controller at the bottom of the vertical grinding barrel, and a timer is built in the controller; a snake-shaped circulating water pipe is evenly wound around the side wall of the vertical grinding barrel; the vertical gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com