Camera mounting position calibration method based on plane mirror

A technology of installation position and calibration method, which is applied in the field of photogrammetry, can solve the problems of high price, high cost of use, and low spatial resolution, and achieve simple and convenient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

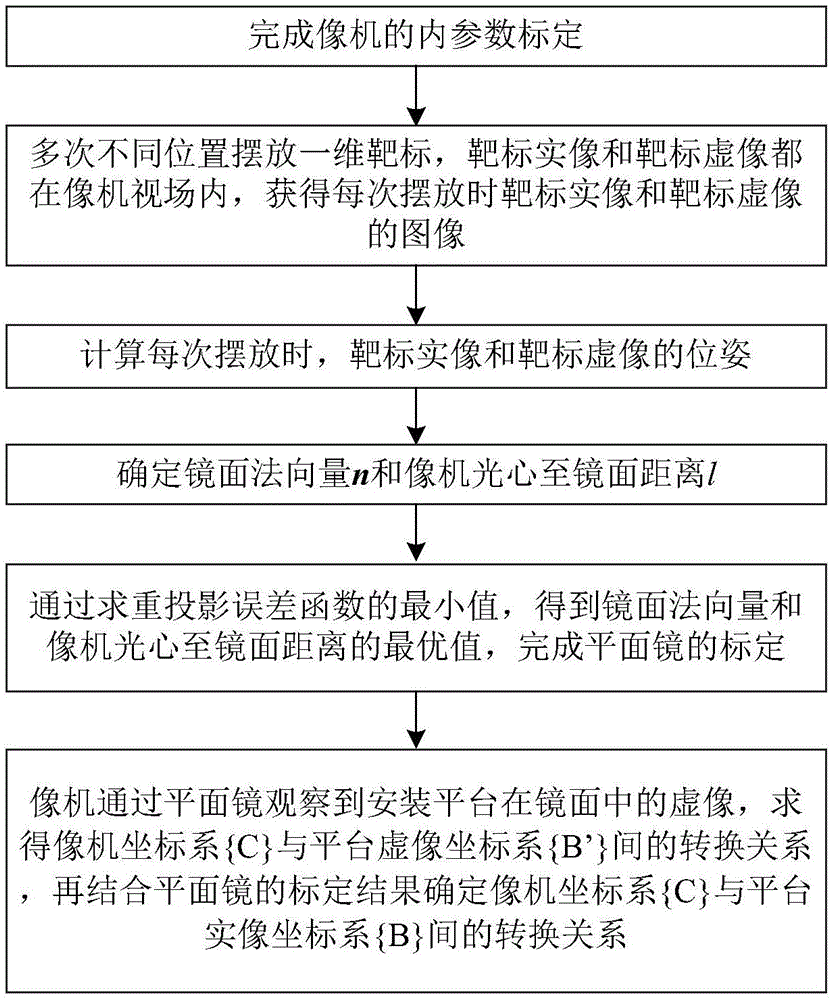

Method used

Image

Examples

Embodiment

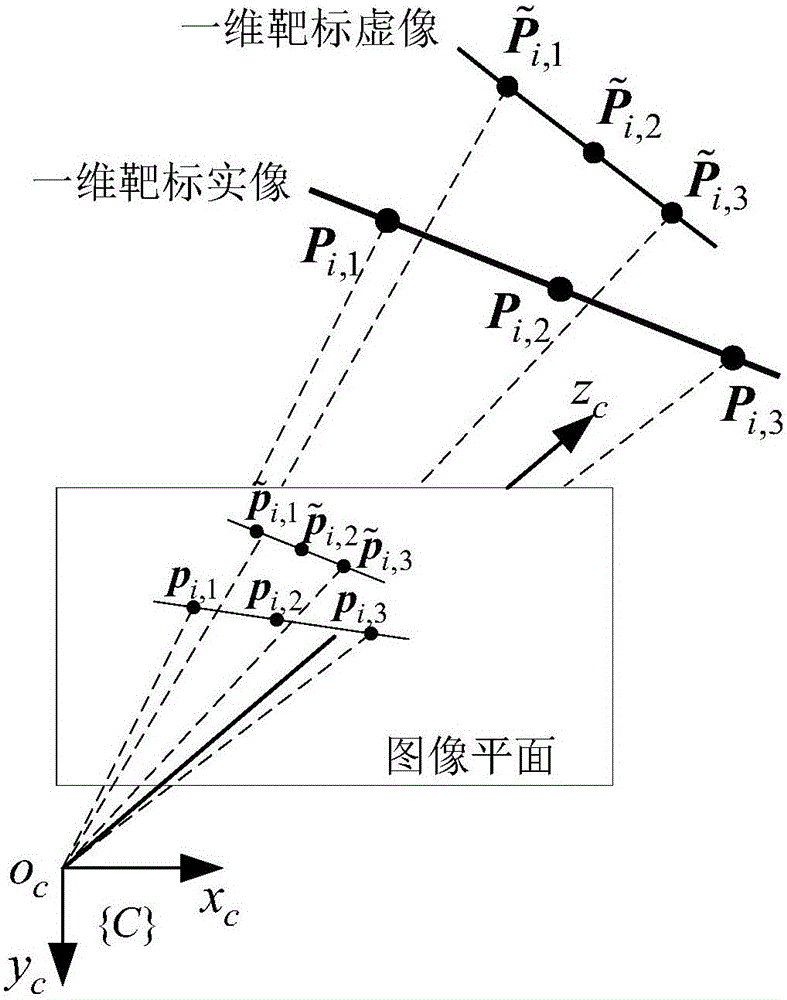

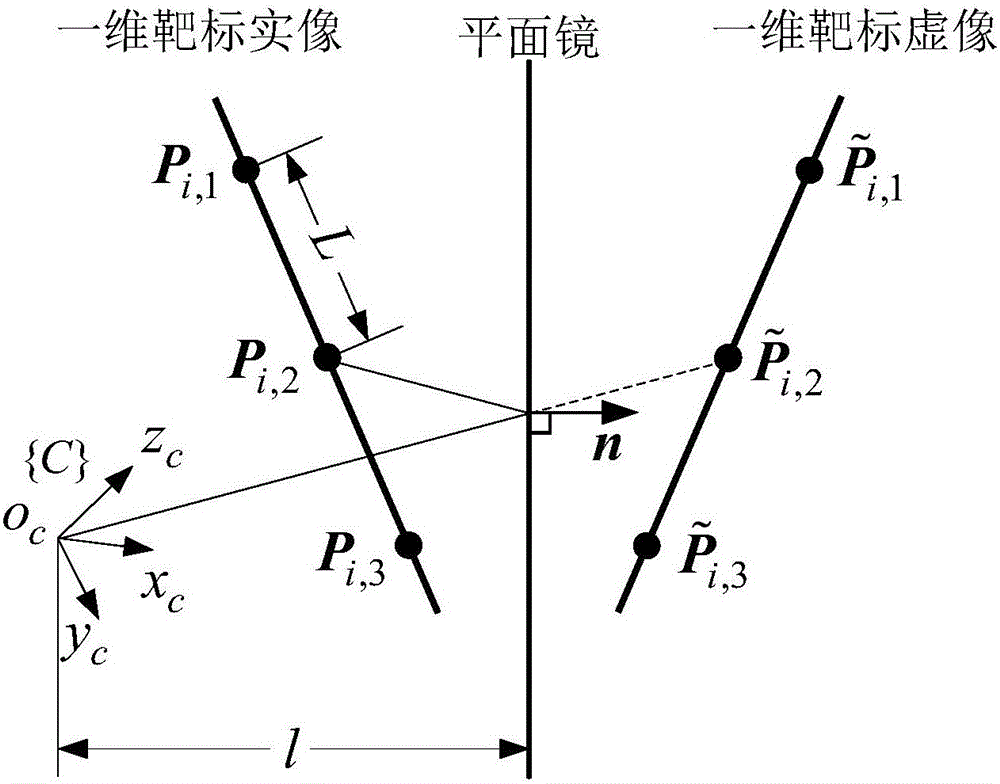

[0082] Mirror pose measurement is a key step in camera installation parameter calibration. In-camera parameter f x = f y =995.556,u 0 = 512 pixels, v 0 =384 pixels, the image resolution is 1024 pixels×768 pixels. Mirror plane normal vector n=[-0.5,0,0.866] T , the distance from the mirror plane to {C} is l=400mm, and the distance between adjacent feature points is L=25mm.

[0083] Define the mirror normal vector error E n , the distance error E from the mirror surface to the optical center l and the reprojection error E q :

[0084] E n = arccos ( n T n g ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com