Waste cable insulating layer stripping device

A technology for waste cables and insulating layers, which is used in electronic waste recycling, equipment for dismantling/armoring cables, and recycling technology, etc. The effect of reducing safety hazards and improving peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

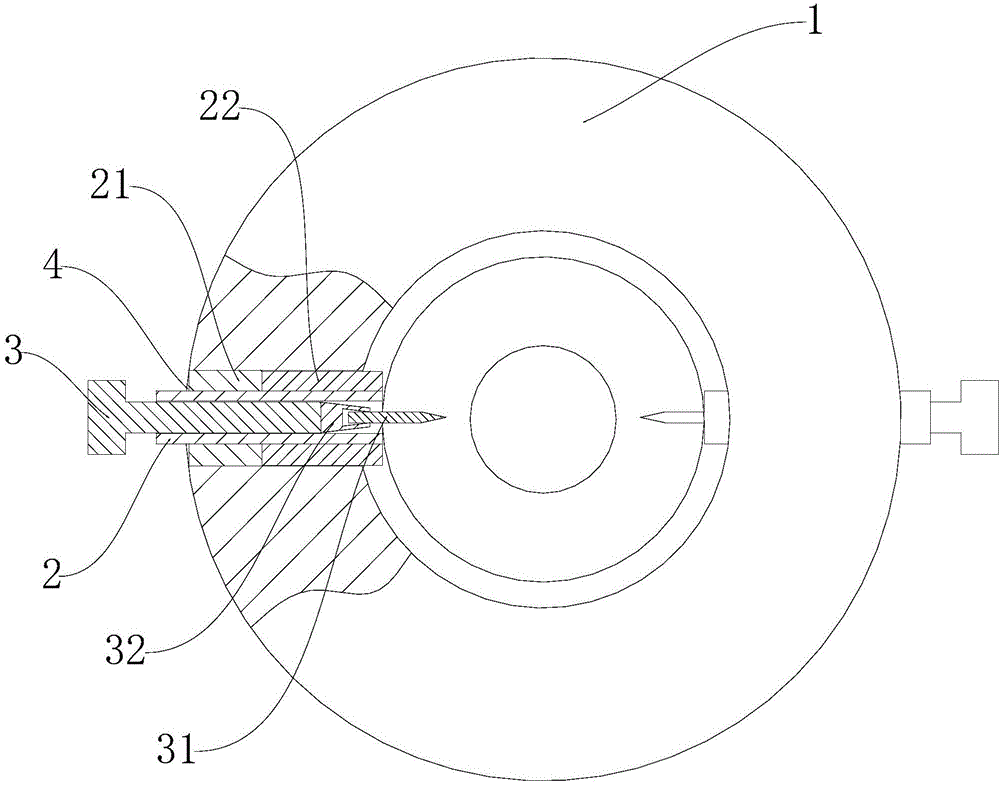

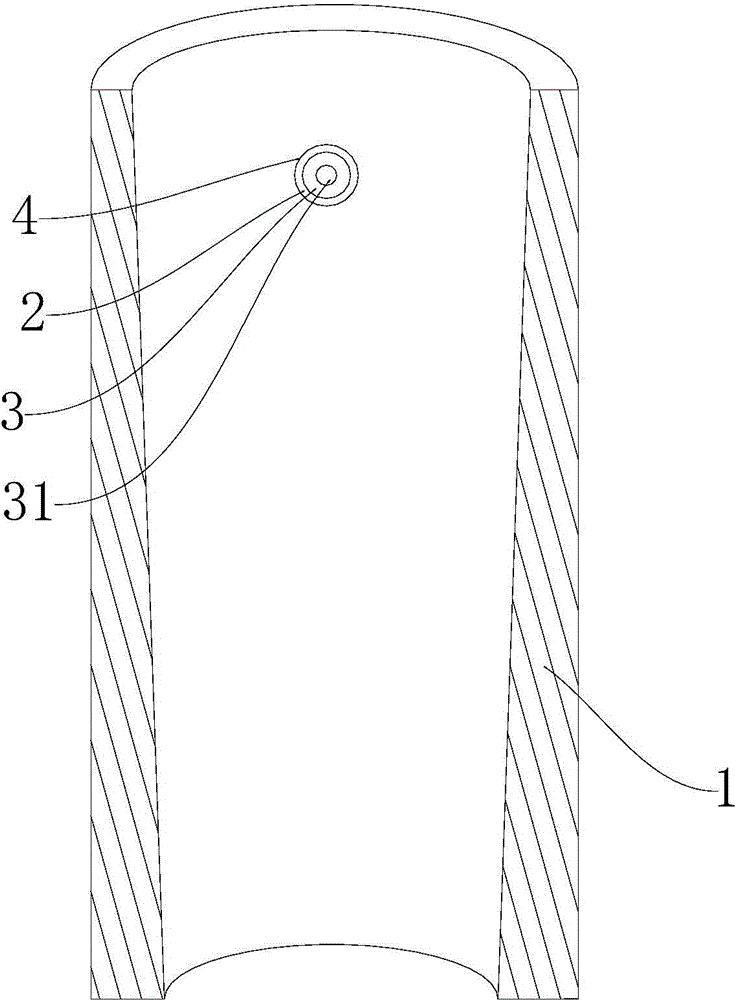

[0022] Such as figure 1 with figure 2 As shown, a waste cable insulation layer stripper includes a fixed barrel 1 with both ends open, a knife barrel 2 with both ends open, and a knife shaft 3, the inner diameter of one end of the fixed barrel 1 is larger than the inner diameter of the other end, There are two radially symmetrically arranged through holes 4 which penetrate the outer and inner walls of the fixed cylinder 1 on the cylinder wall at the larger end of the inner diameter of the fixed cylinder 1. The inner wall of the through hole 4 is provided with a first thread, and the outer wall of the knife cylinder 2 A threaded portion 21 that can be threaded with the first thread and a deformed portion 22 with a diameter smaller than the diameter of the threaded portion 21 are sleeved. The inner wall of the tool barrel 2 is provided with a second thread, and the tool shaft 3 is provided with a second threaded thread. With the matching third thread, a diamond-shaped blade 31 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com