Waste cable insulating layer stripper

A technology for waste cables and insulating layers, which is applied in dismantling/armoring cable equipment, electronic waste recycling, recycling technology, etc., can solve the problems of increasing labor load and low efficiency of workers, and achieve improved stripping efficiency, The effect of improving work efficiency and improving the peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

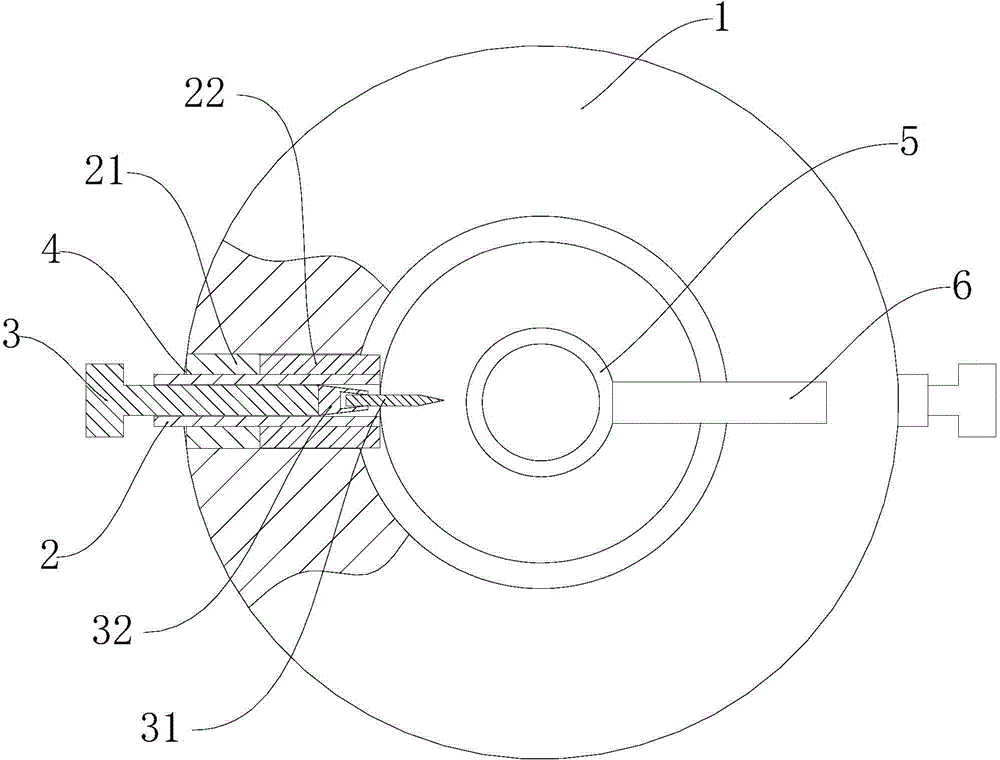

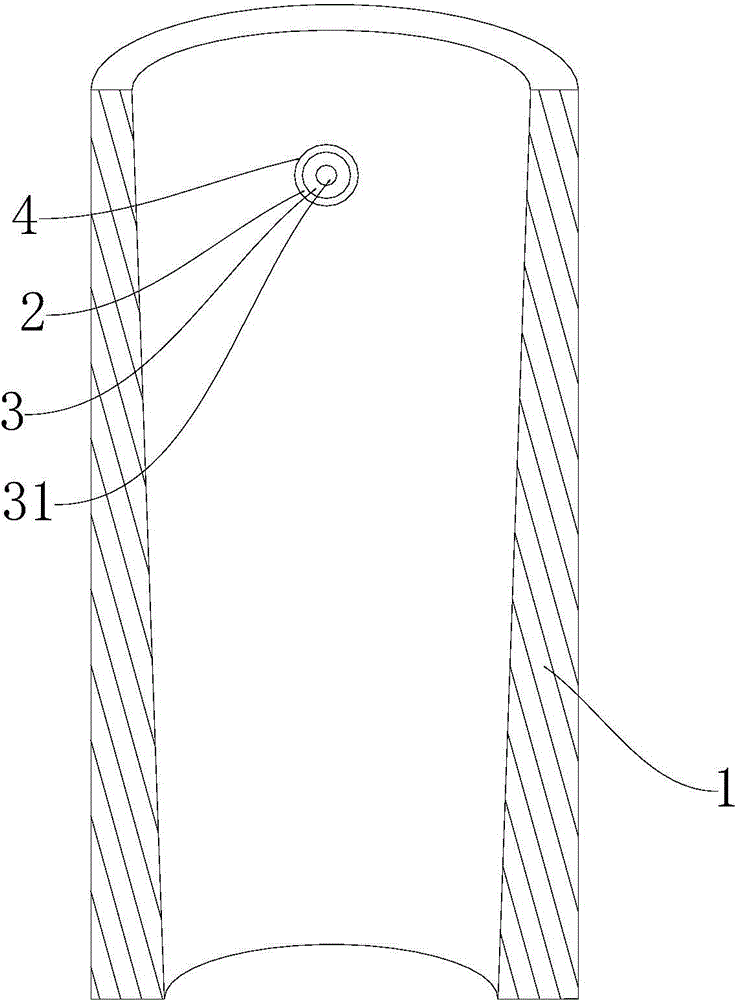

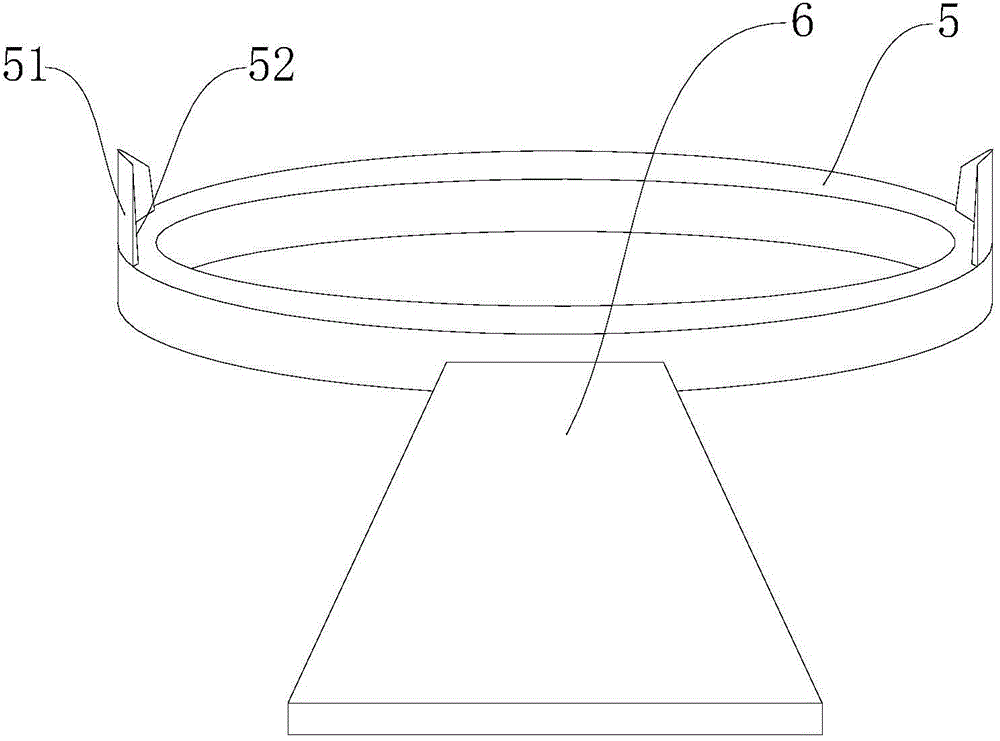

[0026] like Figure 1 to Figure 3 As shown, the stripper for the insulation layer of waste cables includes a fixed cylinder 1 with openings at both ends, a knife cylinder 2 with both ends open, a knife rod 3 and a coaxial arrangement with the fixed cylinder 1 and the diameter of the outer ring is smaller than that of the fixed cylinder 1 The guide ring 5 of the inner wall diameter, the inner diameter of one end of the fixed cylinder 1 is larger than the inner diameter of the other end, and the inner diameter of the fixed cylinder 1 is larger. Hole 4, the inner wall of through hole 4 is provided with first screw thread, and the outer wall of described cutter cylinder 2 is provided with threaded part 21 and the deformation part 22 that diameter is less than threaded part 21 diameters that can cooperate with first screw thread thread, and cutter barrel 2 The inner wall of the knife bar 3 is provided with a second thread, and the knife bar 3 is provided with a third thread thread ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com