Riveting machine for riveting circuit board

A technology for riveting machines and circuit boards, applied in the field of riveting machines, can solve the problems of unstable riveting, hidden dangers of safe operation, and uneven warping and deformation of the bottom of rivets, so as to increase friction and avoid slippage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

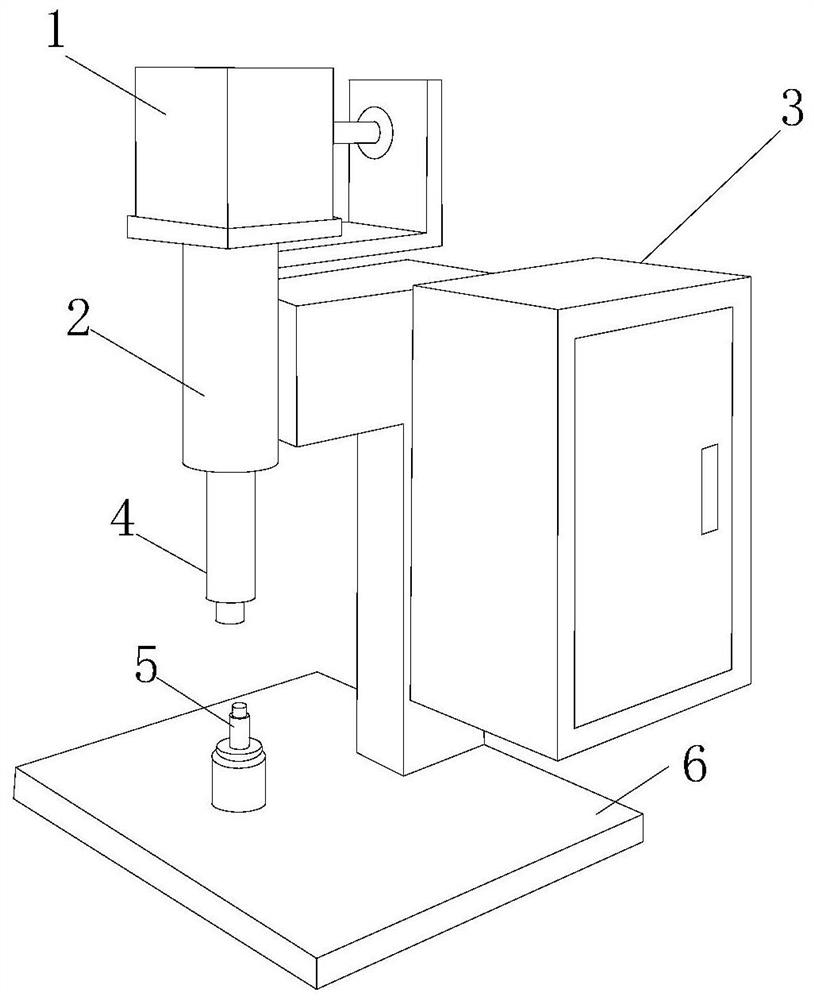

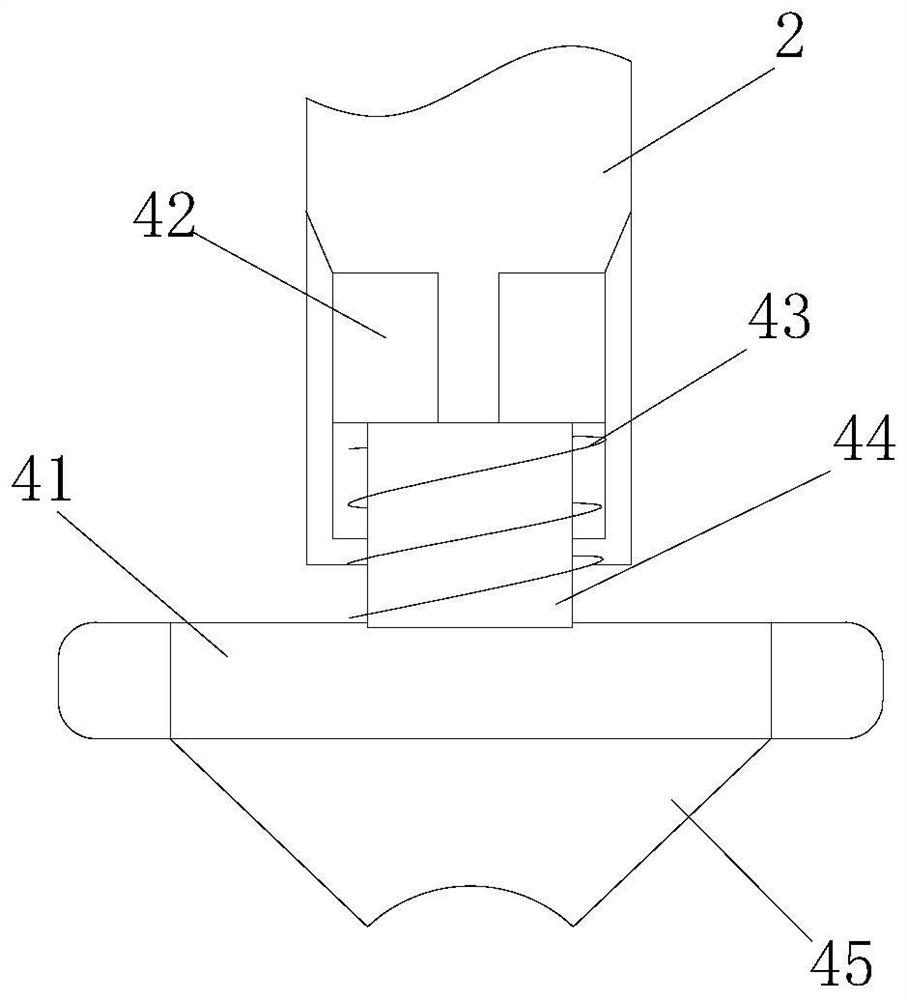

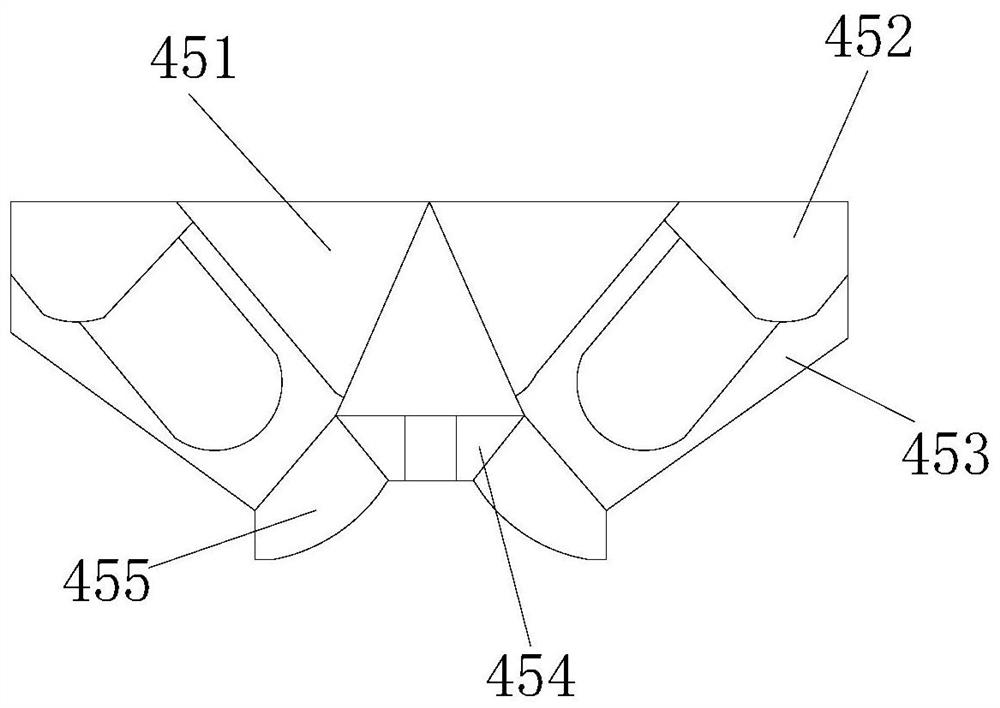

[0028] Such as Figure 1-Figure 4 As shown, the present invention provides a riveting machine for circuit board riveting, its structure includes a console 1, a telescopic rod 2, a motor 3, a pressure pin 4, a thimble 5, and a base 6, and the console 1 and the motor 3 pass through The way of electrical connection is matched, and its bottom is fixedly connected with a telescopic rod 2, and the telescopic rod 2 is provided with a pressing pin 4, and the pressing pin 4 and the thimble 5 are indirectly matched together, and the pressing pin 4 includes a pressing pin Disc 41, connecting block 42, spring 43, connecting rod 44, opening and closing buckle 45, the connecting block 42 is welded and connected between the telescopic rod 2 and the connecting rod 44, and the connecting rod 44 is connected with a spring 43 around it, And its bottom is fixedly connected with a pressure plate 41, and the middle part of the pressure plate 41 is equipped with an opening and closing buckle 45, and...

Embodiment 2

[0030] Such as Figure 5-Figure 8 As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components. The pressure collecting assembly 552 includes a ball 2a1, a pocket 2a2, a folding protrusion 2a3, and a running-in belt 2a4. The top of the pocket 2a2 The running-in belt 2a4 is indirectly fitted on the stabilizing device 553. The running-in belt 2a4 is sleeved and connected to the outside of the folded protrusion 2a3, and balls 2a1 are rolled on both sides. The folded protrusion 2a3 includes a subduction groove a31, a groove containing a32, pendulum piece a33, flexible buckle a34, and guide plate a35. The dive groove a31 and guide plate a35 are embedded and connected to both sides of the running-in belt 2a4, and a flexible buckle a34 is sleeved and connected between them. The flexible buckle a34 is internally installed with Containing slot a32 and pendulum piece a33, the flexible buckle a34 is indirectly matche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com