Suspended vertical carbonization furnace

A carbonization furnace and vertical technology, applied in the field of suspended vertical carbonization furnaces, can solve the problems of secondary environmental pollution, long time consumption, occupation of land resources, etc., to meet the requirements of free expansion and sealing, easy temperature control, and high carbonization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

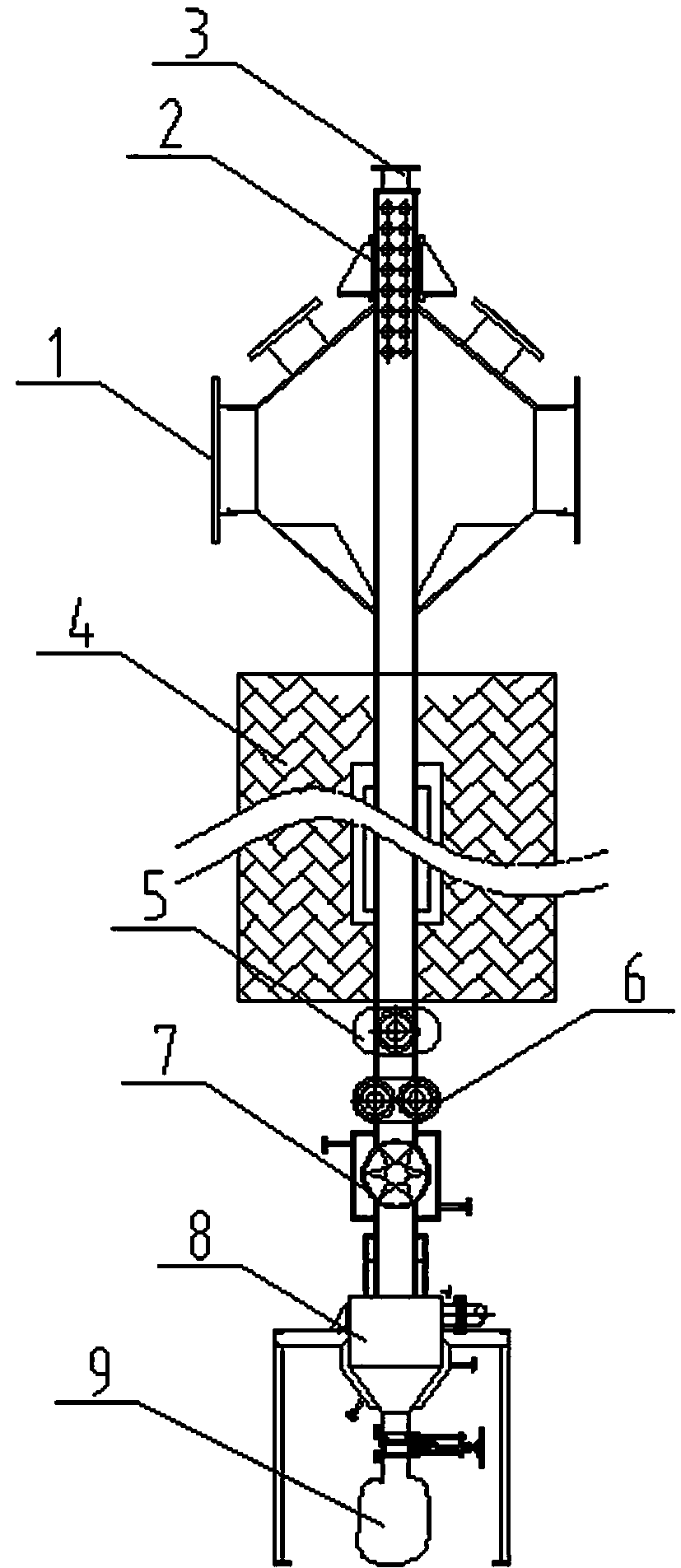

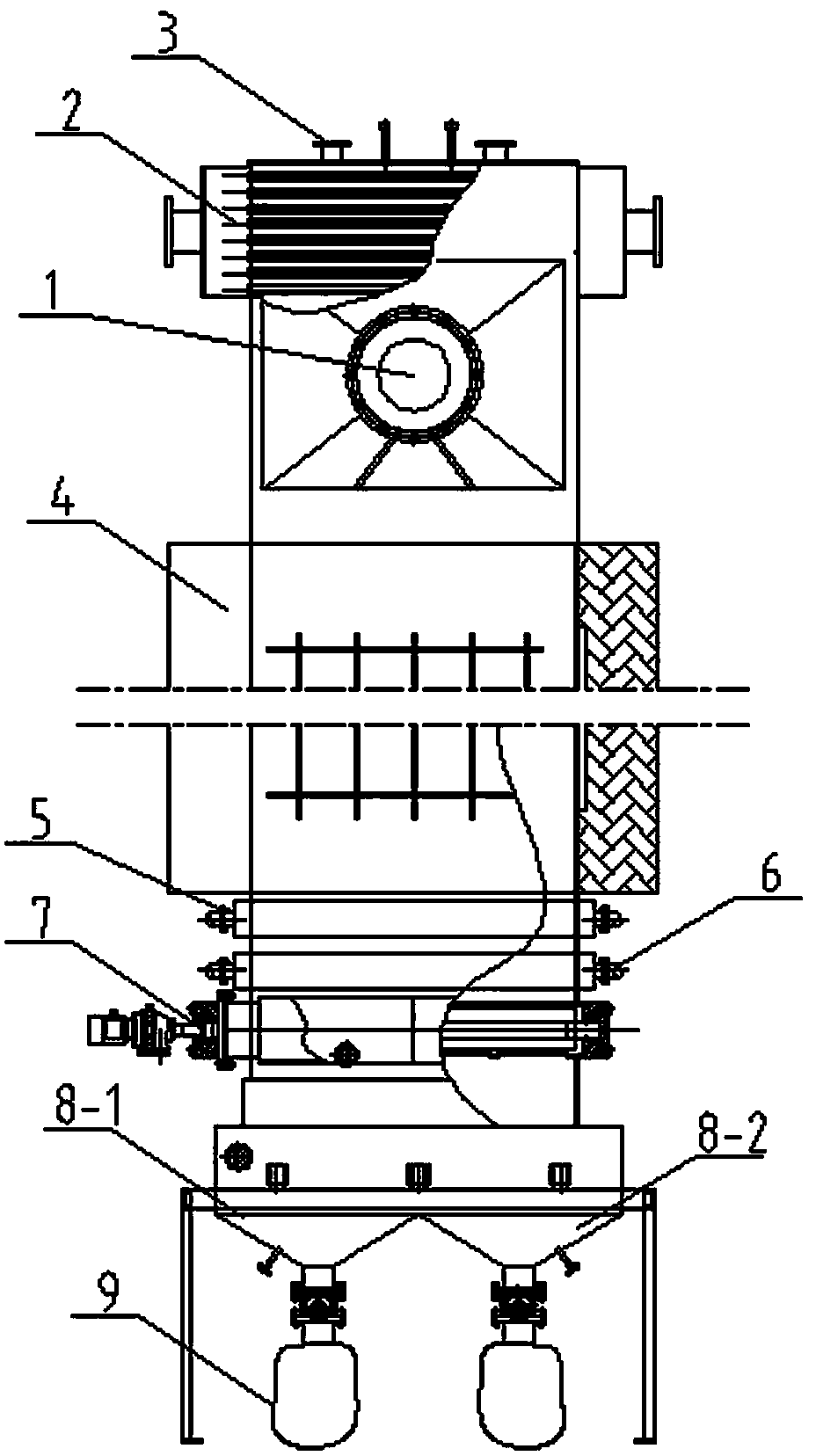

[0022] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

[0023] As shown in the figure, a suspended vertical carbonization furnace includes a feed inlet 1, a heat exchanger 2, a pyrolysis gas outlet 3, a heater 4, a heat exchange pipe 5, a circulating cooling water pipe 6, a rotary feeder 7, an outlet Feed port 8 and receiving box 9. The upper section of the carbonization furnace body is provided with two symmetrical horizontal bucket-shaped feed ports 1, and the feed ports 1 are surrounded by plug-in flange pipe bodies and 4 side cone plates. A deflector is welded on the lower cone plate in 1; a heat exchanger 2 is provided above the feed port in the carbonization furnace, and two pyrolysis gas outlets 3 are provided on the top of the carbonization furnace, and the garbage in the pyrolysis furnace is cracked from After the feed inlet enters, the pyrolysis gas is convected upwards with the heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com