Miniature waveguide filter

A waveguide filter and waveguide technology, applied in waveguide devices, electrical components, circuits, etc., can solve the problems of volume and weight restrictions, and achieve the effect of improving the degree of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

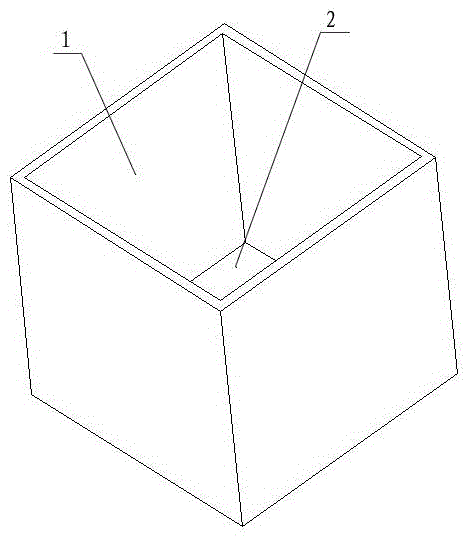

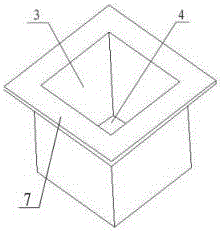

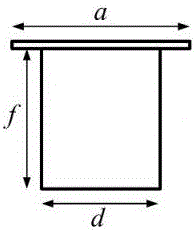

[0028] The present invention provides a miniaturized waveguide resonator. A single concave structure body is embedded in a single waveguide body to form a miniaturized waveguide resonator, such as Figure 1-7 As shown, the external dimensions of the miniaturized waveguide resonator are a=29.2mm, b=29.2mm, c=29.2mm, and the metal thickness is 1mm. The recessed structure is located at the center of the upper surface of the waveguide, d=21.2mm, e=21.2mm , F=24.2mm, d1=5mm, d2=5mm, d3=5mm, d4=5mm, d5=3mm. The resonant frequency of the main mode of the miniaturized waveguide resonator is reduced from 7.8GHz of the conventional waveguide resonator before adding the recessed structure to 2.394GHz after adding the recessed structure. If the conventional waveguide resonator without the recessed structure is used to achieve the main mode resonance of 2.394GHz For frequency, the external dimensions need to be larger as a=90.3mm, b=90.3mm, and c=90.3mm. Compared with a conventional wavegu...

Embodiment 2

[0030] The present invention provides a miniaturized waveguide filter, such as Figure 8 As shown, two miniaturized waveguide resonators are combined by nesting to form a second-order filter, and the coupling between miniaturized waveguide resonators is realized by opening a coupling window on the bonding part of the nested structure, input and output ports The feed is directly completed by the probe; the frequency response of the miniaturized waveguide filter is as Picture 9 As shown, the center frequency is 2GHz, the bandwidth is about 0.19GHz, and the outer maximum size of the miniaturized waveguide filter is only 36×36×51mm 3 .

Embodiment 3

[0032] The present invention provides a miniaturized waveguide filter, such as Picture 10 As shown, three miniaturized waveguide resonators are combined by nesting to form a third-order filter, and the coupling between the miniaturized waveguide resonators is realized by opening a coupling window on the bonding part of the nested structure, input and output ports The feed is directly completed by the probe; the frequency response of the miniaturized waveguide filter is as Picture 11 As shown, the center frequency is 2.6GHz, and the bandwidth is about 0.22GHz. There is a transmission zero at 2.3GHz to effectively improve the lower sideband selectivity. The outer maximum size of the miniaturized waveguide filter is only 25×25×34.8mm. 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com