Clamp connection structure capable of being disassembled and assembled quickly

A connection structure and fast technology, applied in the direction of electrical components, casings/cabinets/drawer parts, electrical equipment casings/cabinets/drawers, etc., can solve the problems of inconvenient disassembly, reduced matching strength, inconvenient disassembly and assembly, etc. , to achieve the effect of ensuring convenience, high structural strength and strengthening assembly strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

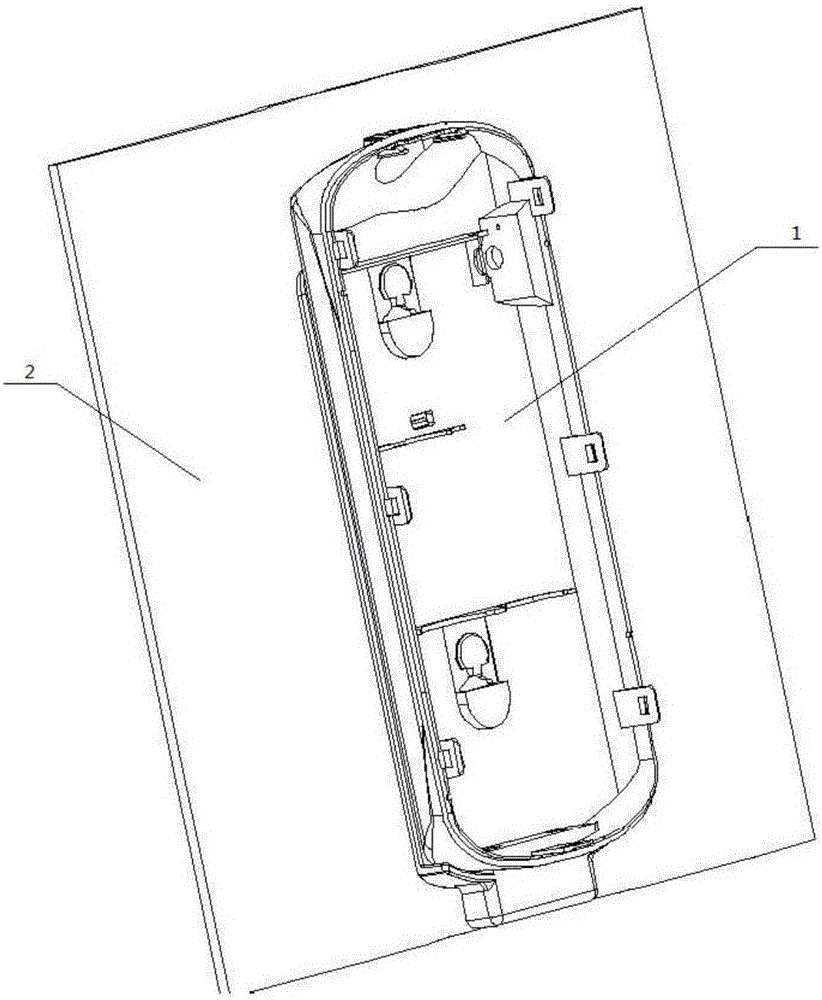

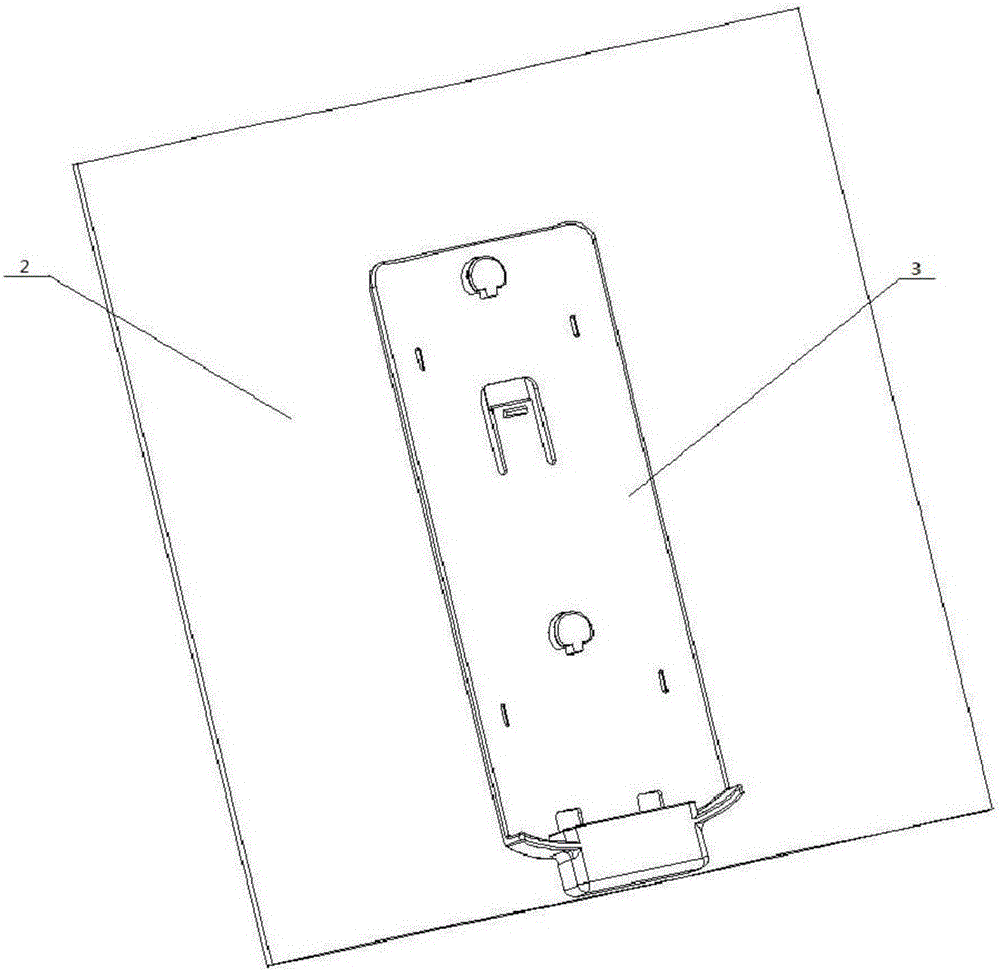

[0046] Such as figure 1 , 2 As shown, the overall diagram of a quick-detachable clamping structure includes a main body 1, a wrapping cloth 2, and a bottom plate 3. The wrapping cloth is made of soft fibers and is fixedly connected with the bottom plate with glue. The product needs to connect the main body and the wrapping The cloth is detachably connected, and the present invention is assembled by sticking the bottom plate on the wrapping cloth, and then assembling the bottom plate and the main body through snap-fit mounting and dismounting.

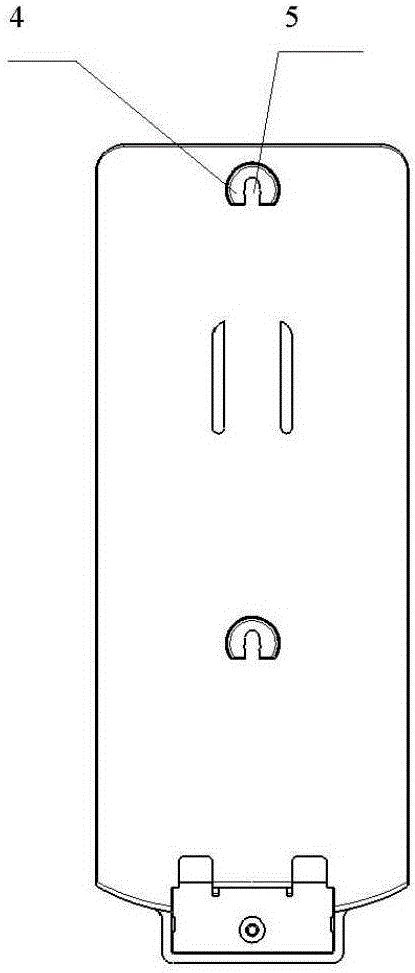

[0047] Base structure such as Figure 3-7 As shown, there is a T-shaped protruding structure and a shrapnel 6 structure on the bottom plate, and buckles 7 are arranged on the shrapnel, and the T-shaped protruding structure is formed by a vertical combination of a T-pillar 5 and a T-surface 4 . T-shaped protruding structures such as Figure 8-11 shown.

[0048] Body 1 is structured like Figure 12-15 As shown, there are T-surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com