Sealed cable entry devices passing through the outer and inner walls of the containment vessel of a nuclear power plant

A technology for introducing devices and sealing cables, which is applied in the field of electrical engineering and can solve problems such as damage to insulation sheaths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

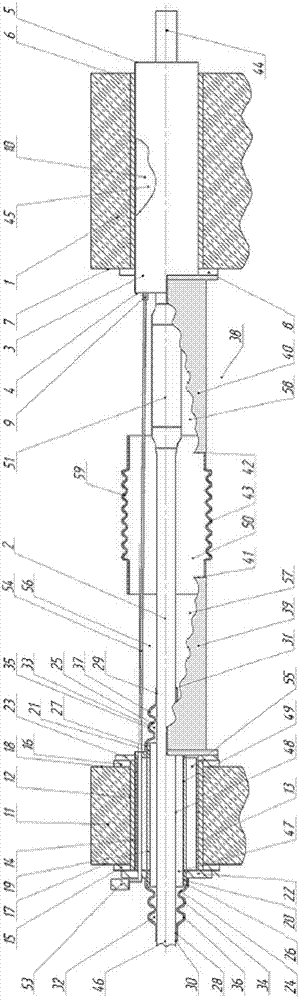

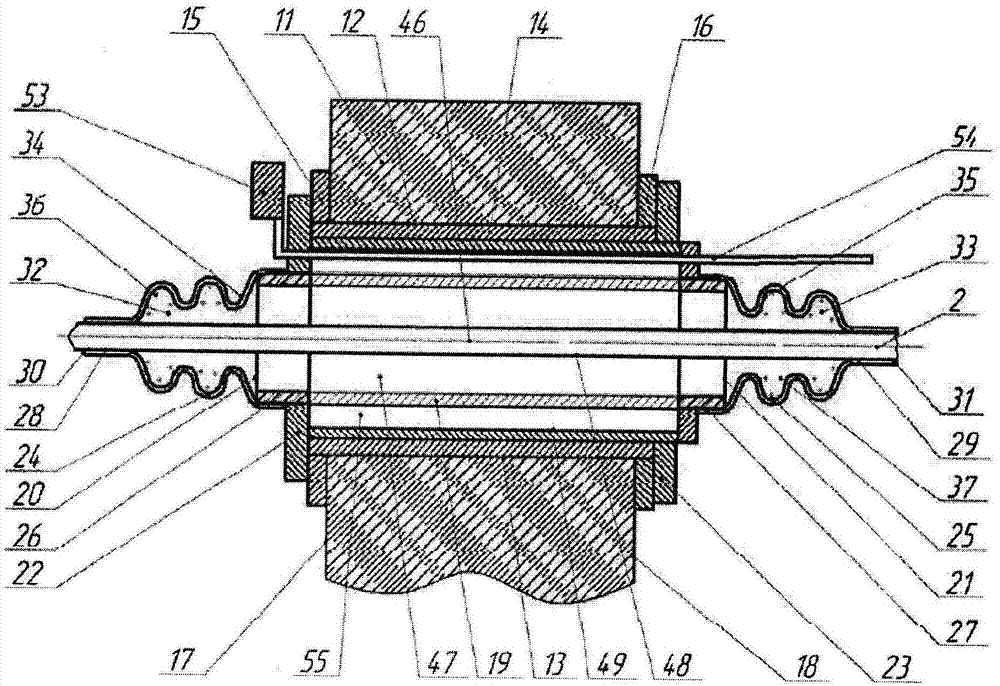

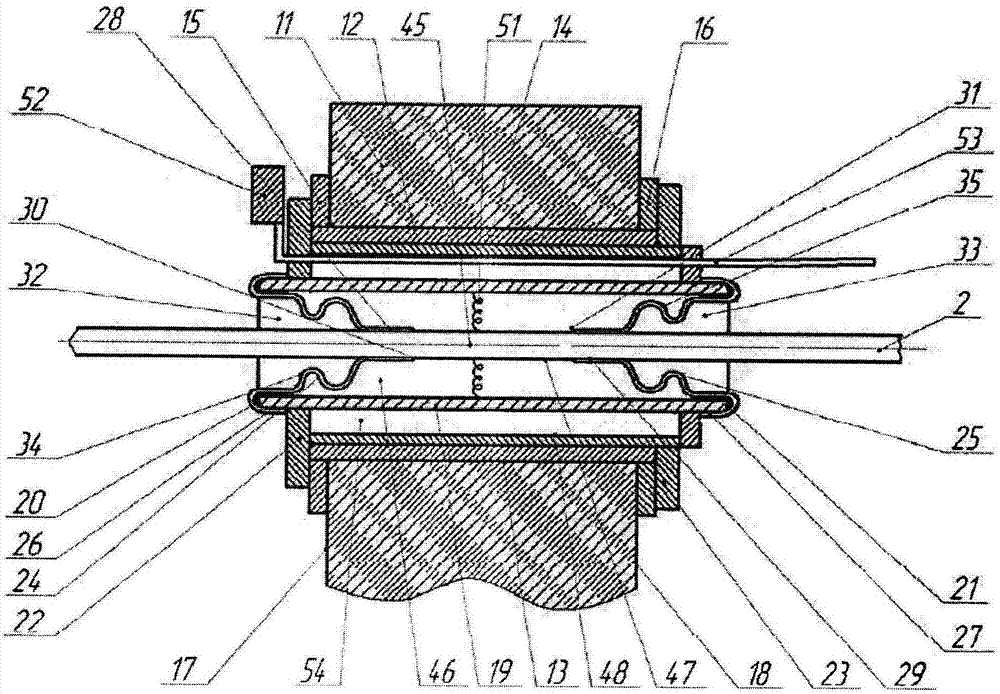

[0026] The sealed cable lead-in device passing through the outer wall and inner wall of the containment vessel of a nuclear power plant includes a first penetration assembly composed of embedded sleeves 3 fixed in the reinforced concrete inner wall 1, and the cables 2 in the penetration assembly are stable. The inner wall 1 is arranged in a sealed dome shape with an average thickness of about 1.2 meters, and its function is to ensure that the remaining internal pressure can be preserved when an accident occurs in the containment. The ends 4 and 5 of the sleeve 3 protrude a little from the plane of the outer 6 and inner 7 surfaces of the inner wall 1 . The end 4 of the bushing 3 on the side of the inner surface 7 of the wall 1 is fitted with a transition flange 8 enabling a rigid and tight connection of the bushing 3 in the wall 1 . A pipe joint 9 communicating with the cavity 10 of the sleeve 3 is also installed at the end 4 of the sleeve 3 . A hole 12 coaxial with the casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com