Fibrous-bed-based gas reaction apparatus

A technology of reaction device and fiber bed, which is applied in the field of gas reaction device, can solve the problems of high carbon content in fly ash entrained by gas, mixing, waste of energy in fly ash, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

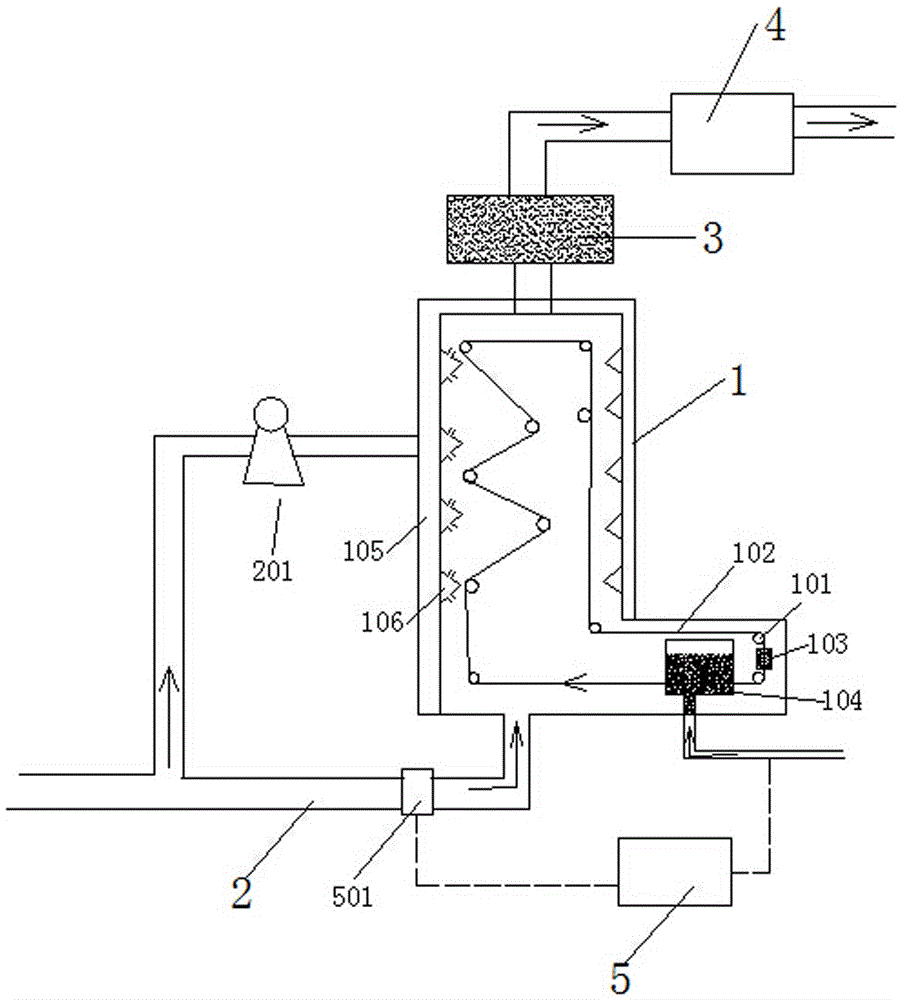

[0026] Specific embodiment 1: as figure 1 , figure 2 As shown, this embodiment discloses a gas reaction device based on a fiber bed, including a reaction tank 1, a steam delivery pipe 2, and a drying layer 3;

[0027] The steam delivery pipe 2 is connected to the bottom of the reaction tank 1, and the top of the reaction tank 1 is connected with a drying layer 3;

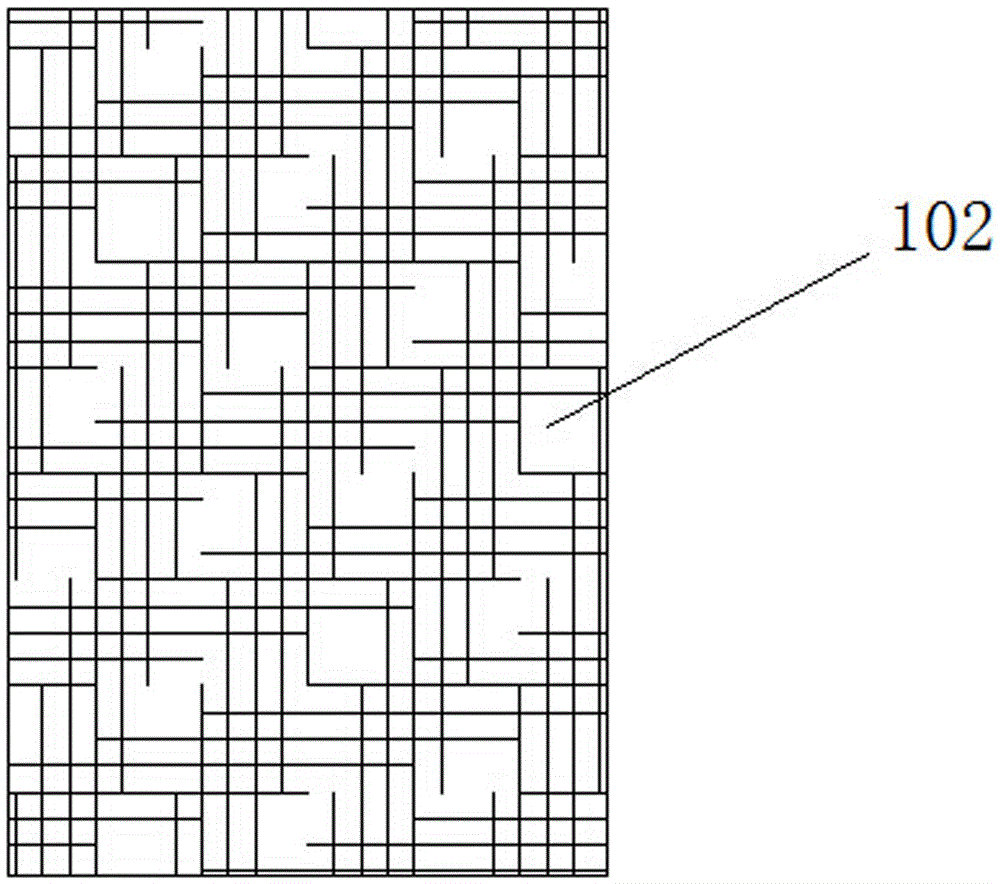

[0028] The inner wall of the reaction tank 1 is provided with a transmission rod 101, and at least one of the transmission rods is connected to an external motor. The transmission rod 101 is provided with a fiber bed 102, and the fiber bed 102 moves through the transmission rod 101, and the reaction A protruding coal ash storage space is provided on one side of the lower end of the tank 1, and the coal ash storage space is provided with a coal ash storage tank 104, the fiber bed 102 passes through the coal ash storage tank 104, and the coal ash storage tank 104 is connected with a coal ash storage tank A supply s...

specific Embodiment 2

[0039] Specific embodiment 2: as figure 1 , figure 2 As shown, this embodiment discloses a gas reaction device based on a fiber bed, including a reaction tank 1, a steam delivery pipe 2, and a drying layer 3;

[0040] The steam delivery pipe 2 is connected to the bottom of the reaction tank 1, and the top of the reaction tank 1 is connected with a drying layer 3;

[0041] The inner wall of the reaction tank 1 is provided with a transmission rod 101, and at least one of the transmission rods is connected to an external motor. The transmission rod 101 is provided with a fiber bed 102, and the fiber bed 102 moves through the transmission rod 101, and the reaction A protruding coal ash storage space is provided on one side of the lower end of the tank 1, and the coal ash storage space is provided with a coal ash storage tank 104, the fiber bed 102 passes through the coal ash storage tank 104, and the coal ash storage tank 104 is connected with a coal ash storage tank A supply s...

specific Embodiment 3

[0052] Specific embodiment 3: as figure 1 , figure 2 As shown, this embodiment discloses a gas reaction device based on a fiber bed, including a reaction tank 1, a steam delivery pipe 2, and a drying layer 3;

[0053] The steam delivery pipe 2 is connected to the bottom of the reaction tank 1, and the top of the reaction tank 1 is connected with a drying layer 3;

[0054] The inner wall of the reaction tank 1 is provided with a transmission rod 101, and at least one of the transmission rods is connected to an external motor. The transmission rod 101 is provided with a fiber bed 102, and the fiber bed 102 moves through the transmission rod 101, and the reaction A protruding coal ash storage space is provided on one side of the lower end of the tank 1, and the coal ash storage space is provided with a coal ash storage tank 104, the fiber bed 102 passes through the coal ash storage tank 104, and the coal ash storage tank 104 is connected with a coal ash storage tank A supply s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com