Automatic cleaning and disinfecting system and cleaning and disinfecting method for milk cows

A cleaning, disinfection, and automatic cleaning technology, applied in cleaning devices, milking devices, dairy products, etc., can solve the problems of inability to solve cleaning and disinfection problems, high system real-time requirements, and short medicated bath operation time, so as to overcome intermittent The effect of running problems, compact space layout, and easy function expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the drawings and embodiments.

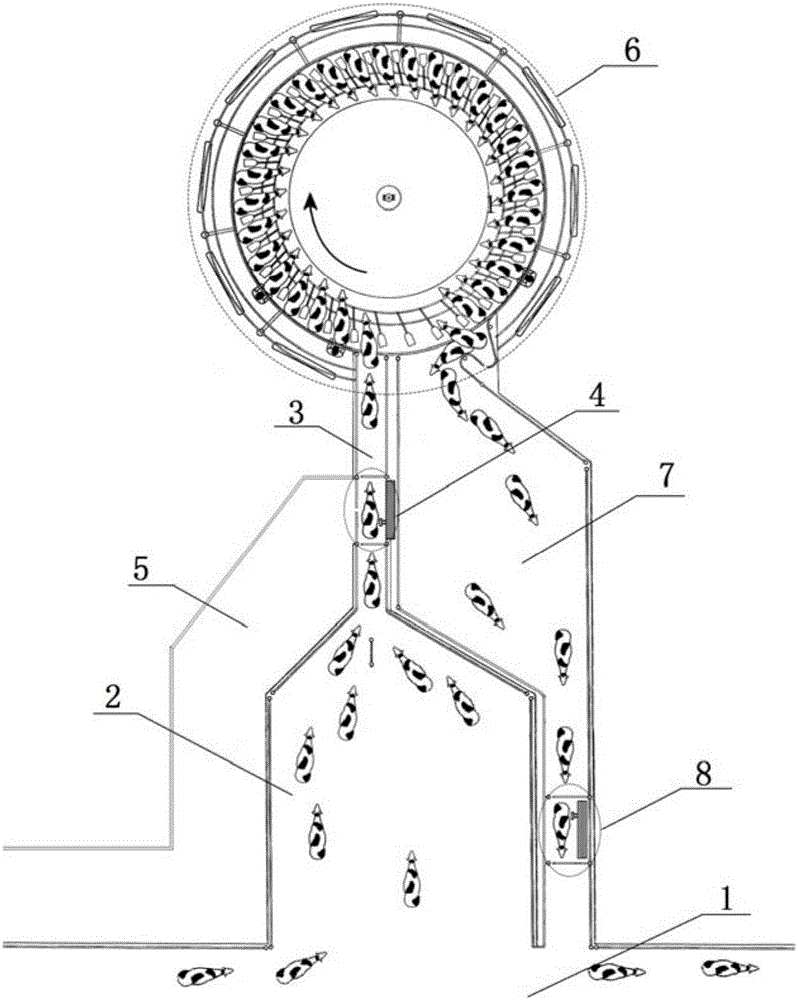

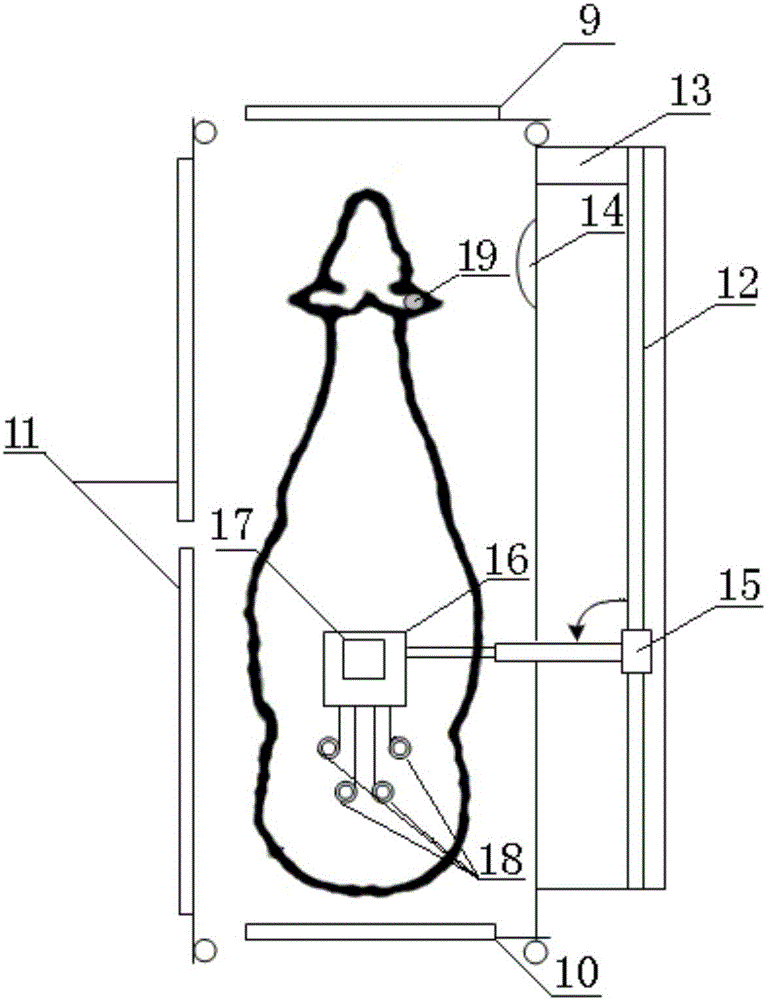

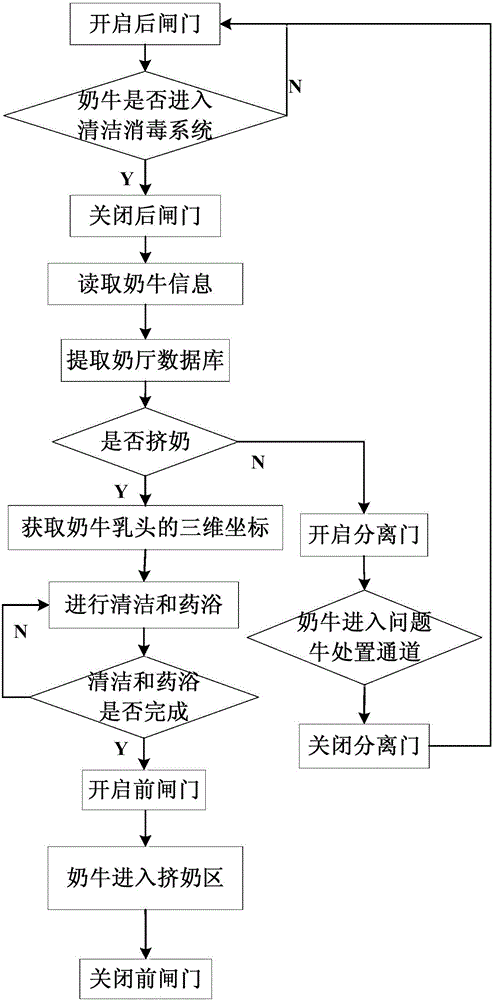

[0022] Such as figure 1 As shown, the present invention provides an automatic cleaning and disinfection system for dairy cows, which includes a swarm channel 1, a waiting area 2, a disinfection channel 3, a cleaning and disinfection system 4, a problematic cattle disposal channel 5, a milking zone 6, a return channel 7 and Disinfection system 8. The swarm channel 1 communicates with one end of the area to be squeezed 2, and the other end of the area to be squeezed 2 communicates with one end of the disinfection channel 3. The disinfection channel 3 is provided with a cleaning and disinfection system 4 for cleaning and medicating the cows before milking. One side of the cleaning and disinfection system 4 is connected to one end of the problematic cattle disposal channel 5, and is used to leave the cows that do not meet the milking requirements through the problematic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com