Hammering device

A horizontal and box-mounted technology, applied in clothing, shoe-making machinery, beating machines, etc., can solve the problem of leather beating equality, achieve the effect of improving efficiency, good effect, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

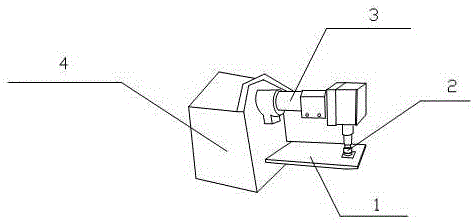

[0018] Such as figure 1 As shown, the present invention includes a support plate 1, a striking head 2, a cross bar 3 and an installation box 4, and a driving device is installed in the installation box 4. The striking head 2 of the present invention is located directly above the support plate 1, the striking head 2 is fixed on the end of the cross bar 3, the striking head 2 can move up and down, the supporting plate 1 corresponding to the bottom of the striking head 2 is provided with a square through hole, The size of the through hole can pass through the beating head 2, and the beating head 2 is cylindrical with smooth surface. The support plate 1 and the cross bar 3 of the present invention are all horizontally fixed on the installation box 4, the installation ends of the support plate 1 and the cross bar 3 are on the same straight line, and there is a certain distance between the support plate 1 and the cross bar 3 in the vertical direction .

[0019] The beating head ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com