A high-efficiency abc dry powder fire extinguishing agent

A dry powder fire extinguishing agent, high-efficiency technology, applied in fire prevention equipment, etc., can solve the problems of low fire extinguishing efficiency, low content of monoammonium phosphate, poor fire extinguishing effect, etc., to improve sports performance, high content of monoammonium phosphate, and good fire extinguishing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The raw material of the main components adopts 820 kilograms of monoammonium phosphate with a purity of 92.71% produced by our company, wherein the content of ammonium sulfate is 2.62%, and other components are purchased from the market. The converted formula is as follows:

[0027] Monoammonium Phosphate

Silica

Quartz sand

silicone oil

activated clay

iron yellow

760kg

152kg

13kg

11kg

6kg

11kg

11kg

0.02kg

[0028] Break the monoammonium phosphate and ammonium sulfate separately; add all the raw materials into the silicification machine (except silicone oil) according to the formula; stir and heat to 60-70°C; spray the emulsion of silicone oil and water; The temperature of the reaction material is 110-115°C; the siliconized reaction material is cooled to below 60°C, screened, and packaged to obtain a high-efficiency ABC dry powder fire extinguishing agent product.

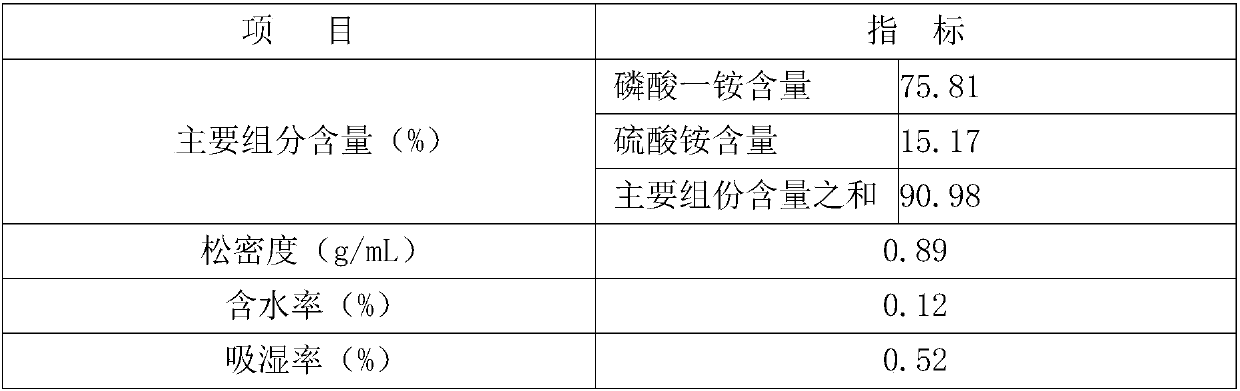

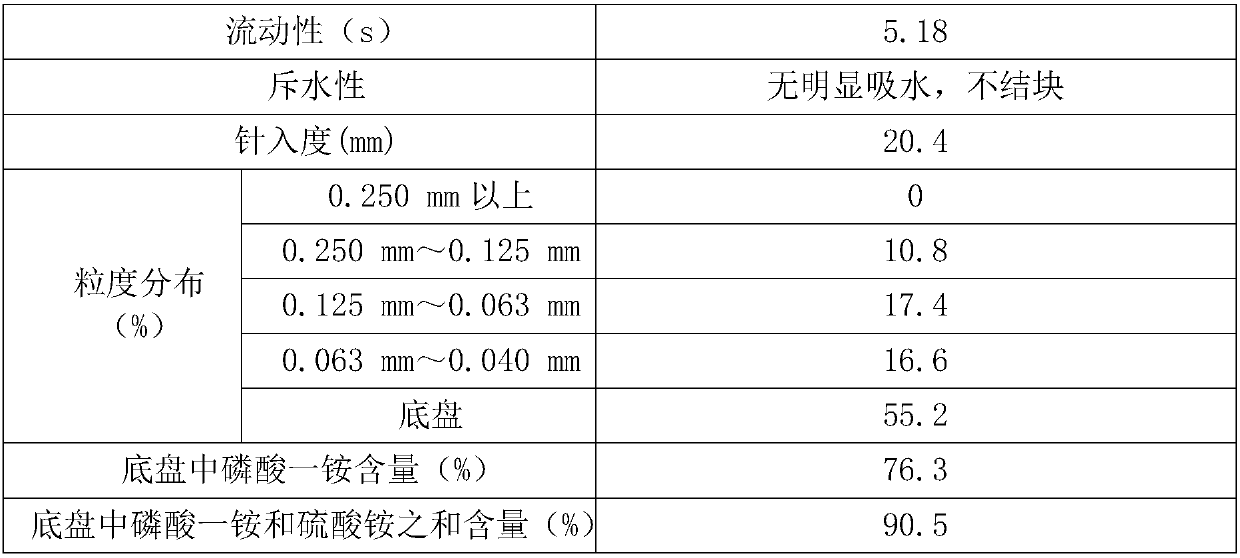

[0029] T...

Embodiment 2

[0033] The raw material of the main components adopts 810 kilograms of monoammonium phosphate with a purity of 96.43% produced by our company, wherein the content of ammonium sulfate is 1.08%, and other components are purchased from the market. The converted formula is as follows:

[0034] Monoammonium Phosphate

ammonium sulfate

Silica

Quartz sand

activated clay

iron yellow

781kg

153kg

25kg

12kg

9kg

25kg

12kg

0.01kg

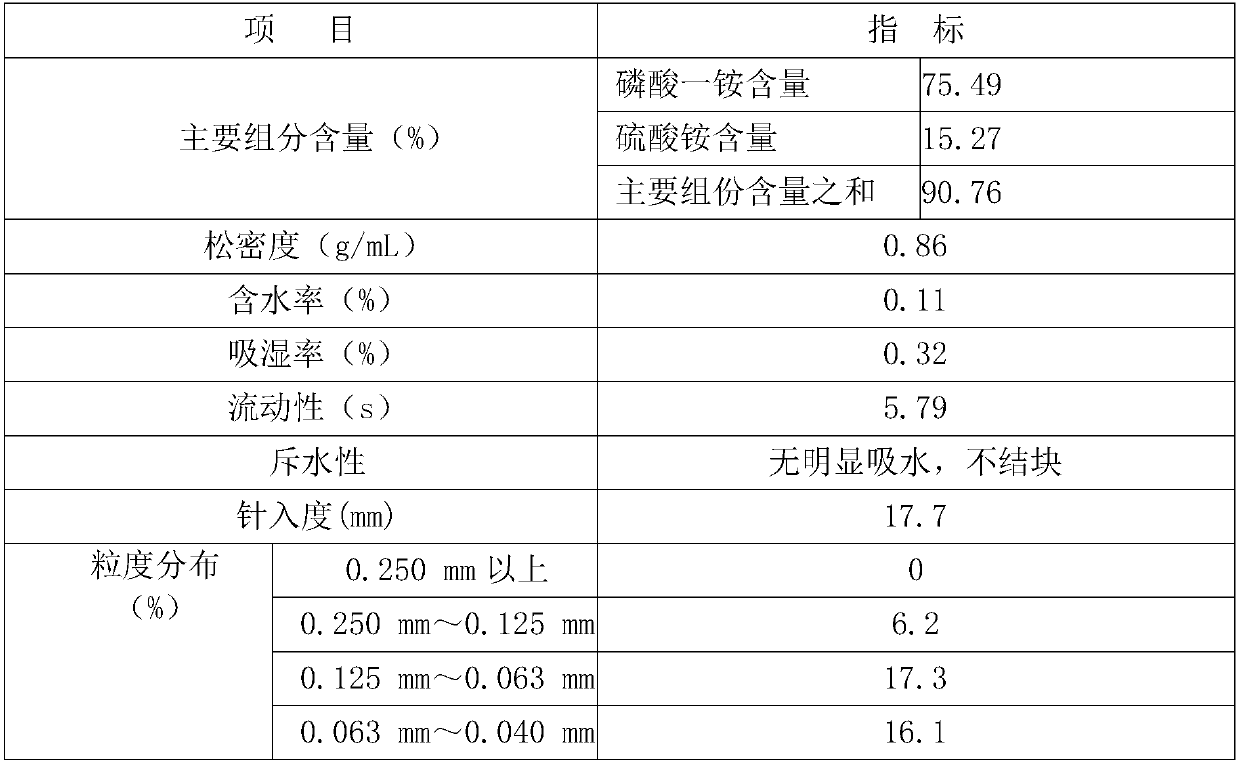

[0035] Break the monoammonium phosphate and ammonium sulfate separately; add all raw materials into the siliconization machine (except silicone oil) according to the formula; stir and heat to 65-75°C; spray the emulsion of silicone oil and water; siliconization reaction for 2.5 hours, siliconization The temperature of the reaction material is 90-95°C; the siliconized reaction material is cooled to below 60°C, screened and packaged to obtain a high-efficiency ABC dry powd...

Embodiment 3

[0040] The raw material of the main components adopts 816 kilograms of monoammonium phosphate with a purity of 94.39% produced by our company, wherein the content of ammonium sulfate is 3.12%, and other components are purchased from the market. The formula after conversion is as follows:

[0041] Monoammonium Phosphate

ammonium sulfate

Silica

Quartz sand

silicone oil

activated clay

lead chrome yellow

770kg

156kg

10kg

26kg

5kg

15kg

21kg

0.01kg

[0042] Break the monoammonium phosphate and ammonium sulfate separately; add all raw materials into the siliconization machine (except silicone oil) according to the formula; stir and heat to 75-85°C; spray the emulsion of silicone oil and water; siliconization reaction for 2 hours, siliconization The temperature of the reaction material is 105-110°C; the siliconized reaction material is cooled to below 60°C, screened, and packaged to obtain a high-efficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com