Filter quantity meter, filter quantity metering method, filter element with metering function and filter

A filter and filter capacity technology, which is applied in the field of filter capacity, can solve problems such as increased energy consumption, difficult water and electricity isolation, and insecurity, and achieve the effects of simplified structure, sensitive capture, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

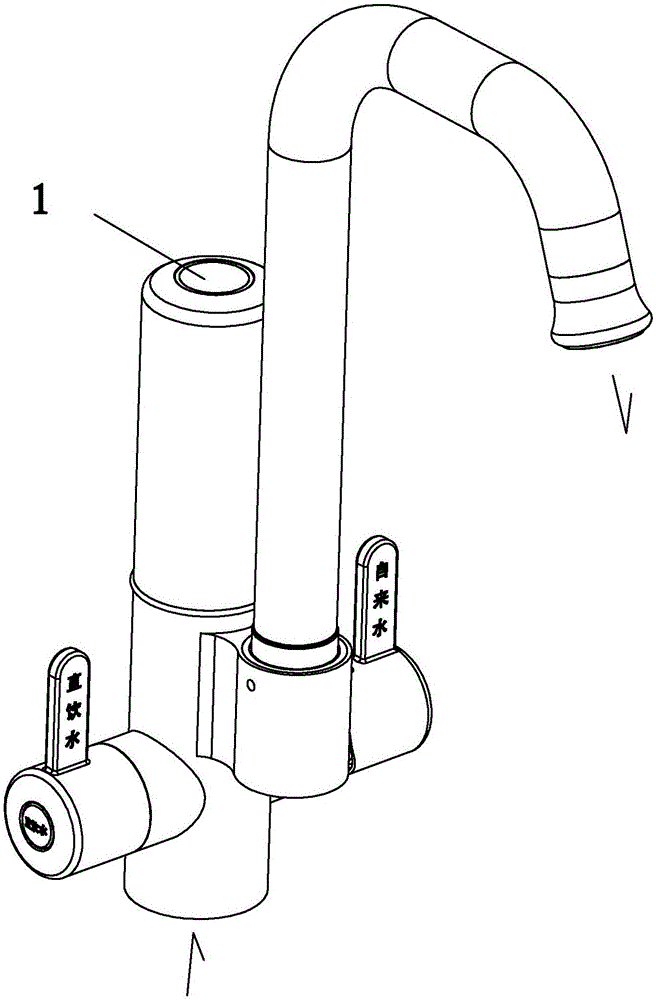

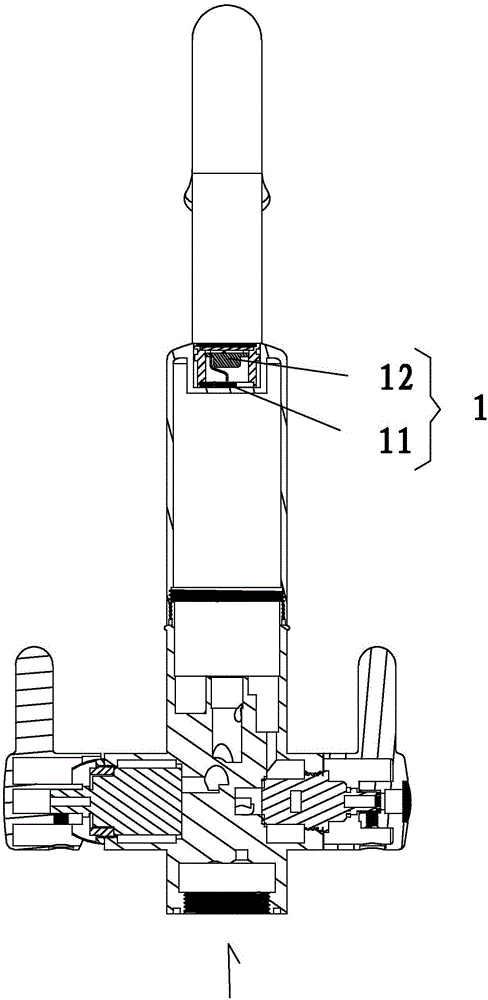

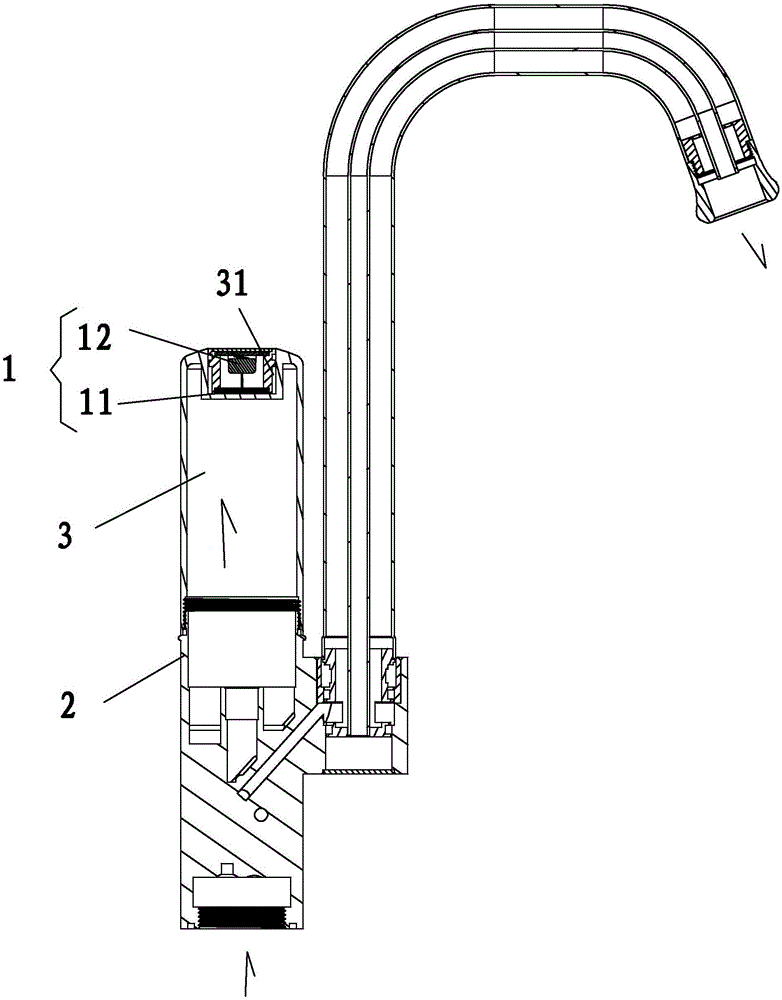

[0026] like Figure 1 to Figure 3 As shown, the filter meter 1 of this embodiment mainly includes a vibration sensor 11 and a metering mechanism 12 . The filtration meter in this embodiment can also be called a filtration flow meter.

[0027] Vibration sensor 11 can adopt existing structure. The sensing end of the vibration sensor can sense various vibrations caused by the measured medium, even tiny vibrations. The output end of the vibration sensor is connected to the input end of the metering mechanism. For example, the sensor can be made of high molecular polymer film, made of optical fiber and other sensors.

[0028] The metering mechanism 2 can adopt existing various metering institutions, electronic metering institutions, or liquid flowmeters and gas flowmeters, or flowmeters can be divided into differential pressure flowmeters, rotameters, throttling flowmeters, and fine flowmeters. Slit flowmeter, volume flowmeter, electromagnetic flowmeter, ultrasonic flowmeter an...

Embodiment 2

[0035] The flow metering method of this embodiment is the specific metering method of the first embodiment, which starts metering the parameters of the metered medium through the control module according to the signal generated by the vibration caused by the metered medium.

[0036] When this embodiment is used to measure the filtered medium, the method for measuring the filtration volume of the filtered medium is as described above.

Embodiment 3

[0038] Embodiment The filter element with metering is the specific application of the first and second embodiments. The metered filter element mainly includes filter material and filter meter. The filter meter adopts any structure as mentioned above, and the similarities will not be repeated here.

[0039] Preferably, the filter element with metering also includes a filter housing and a display mechanism. The filter material is arranged in the filter housing, and the filter housing is provided with filter holes for the metered medium to enter and exit. The metering mechanism and the display mechanism are arranged on the filter housing.

[0040] Preferably, a metering mechanism and a display mechanism are arranged outside the filter housing, which can shield the influence of the metered medium on the metering mechanism and the display mechanism, and effectively protect the metering mechanism and the display mechanism.

[0041] Wherein, the sensing end of the vibration sensor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com