Precise-amplification microreactor and preparation method application thereof

A micro-reactor and precise technology, applied in the field of micro-chemical industry, can solve the problems of difficult connection, channel sealing, packaging difficulty, unstable contact, etc., and achieve the effect of broad application prospects, simple operation method and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

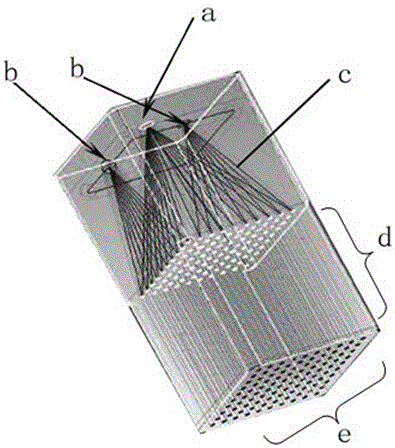

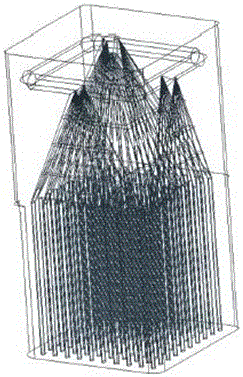

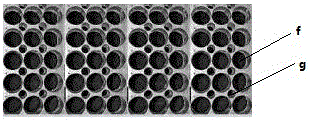

[0048] The accurately enlarged microreactor includes a feed inlet, 1000 channels, a feed outlet and connecting pipes. The diameter of the discharge pipe connected between the feed pipes from the feed inlet to the discharge inlet of the feed pipe gradually changes from large to small; the diameter of the feed pipe from the feed inlet to the discharge inlet of the feed pipe gradually changes from 0.5mm to 0.2mm , a single heat exchange unit is provided on a single channel, and the heat exchange unit includes a single heat exchange channel and its connecting pipes and liquid inlet and outlet (such as image 3 shown).

[0049] The precisely enlarged microreactor is applied in the process of liquid-liquid solvent extraction, especially the extraction reaction involving the separation of copper and iron.

[0050] The precisely enlarged microreactor preparation method, its specific steps are as follows:

[0051] (1) Study the reaction characteristics of the single channel to be enl...

Embodiment 2

[0061] The accurately enlarged microreactor includes a feed inlet, 10,000 channels, a feed outlet and connecting pipes. The diameter of the discharge pipe connected between the feed pipes from the feed inlet to the discharge inlet of the feed pipe gradually changes from large to small; the diameter of the feed pipe from the feed inlet to the discharge inlet of the feed pipe gradually changes from 0.5mm to 0.2mm , a single heat exchange unit is provided on a single channel, and the heat exchange unit includes a single heat exchange channel and its connecting pipes and liquid inlet and outlet (such as image 3 shown).

[0062] Apply the precisely enlarged microreactor to the gas absorption in the gas-liquid reaction, especially the reaction involving the absorption of hydrogen sulfide gas by dilute lye.

[0063] The precisely enlarged microreactor preparation method, its specific steps are as follows:

[0064] (1) Study the reaction characteristics of the single channel to be ...

Embodiment 3

[0075] The accurately enlarged microreactor includes a feed inlet, 100 channels, a feed outlet and connecting pipes. The diameter of the discharge pipe connected between the feed pipes from the feed inlet to the discharge inlet of the feed pipe gradually changes from large to small; the diameter of the feed pipe from the feed inlet to the discharge inlet of the feed pipe gradually changes from 0.5mm to 0.2mm , a single heat exchange unit is provided on a single channel, and the heat exchange unit includes a single heat exchange channel and its connecting pipes and liquid inlet and outlet (such as image 3 shown).

[0076] Application of precisely scaled-up microreactors for gas absorption in liquid-liquid reactions, especially for In 3+ and Fe 3+ , Zn 2+ microfluidic extraction separation.

[0077] The precisely enlarged microreactor preparation method, its specific steps are as follows:

[0078] (1) Study the reaction characteristics of the single channel to be enlarged,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com