Mixed carbonization treatment method of plant fiber and sludge in garbage undersize

A plant fiber and carbonization treatment technology, which is applied to chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of large hazards, long fermentation treatment cycle, and large floor area, and achieve fast fiber carbonization speed , realize the effect of resource utilization and heat exchange rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

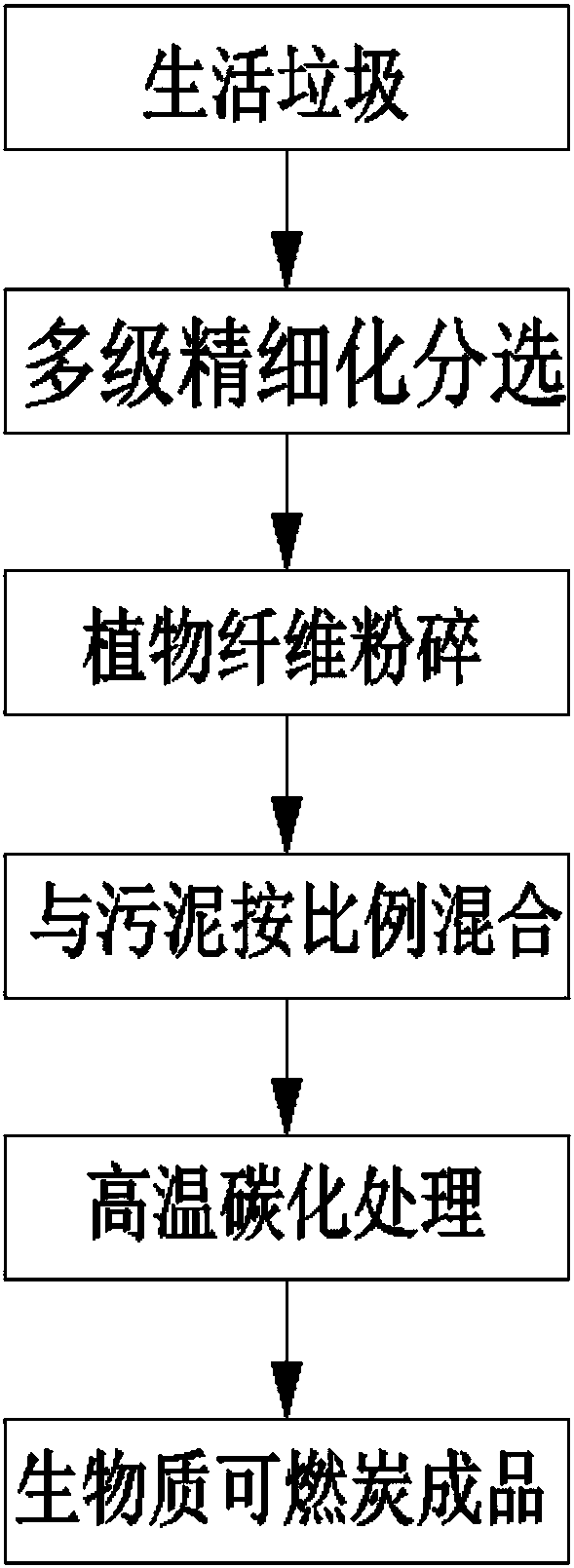

[0035] Such as figure 1 As shown, a mixed carbonization treatment method of plant fibers and sludge in garbage undersize, the treatment steps are as follows:

[0036] The first step is the multi-level fine sorting process, which is to finely classify the undersieve of domestic waste according to the composition, and subdivide into inorganic substances, metals, plastic petroleum products, plant fibers, animal carcasses, Six categories of substances such as batteries or electronic products, and select useful waste rich in plant fibers; the specific steps in this example are:

[0037] Step 1: First unpack the packaged domestic waste according to the size, and perform a first-level manual classification, sort out and classify the large-sized clothing, wood, and building materials waste in the waste, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com