NOTE unmanned automatic production line

A technology for automated production lines and drive mechanisms, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as failure to achieve automated production goals, simplify structural design and equipment maintenance efficiency, improve operational stability, and ensure The effect of combined power and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

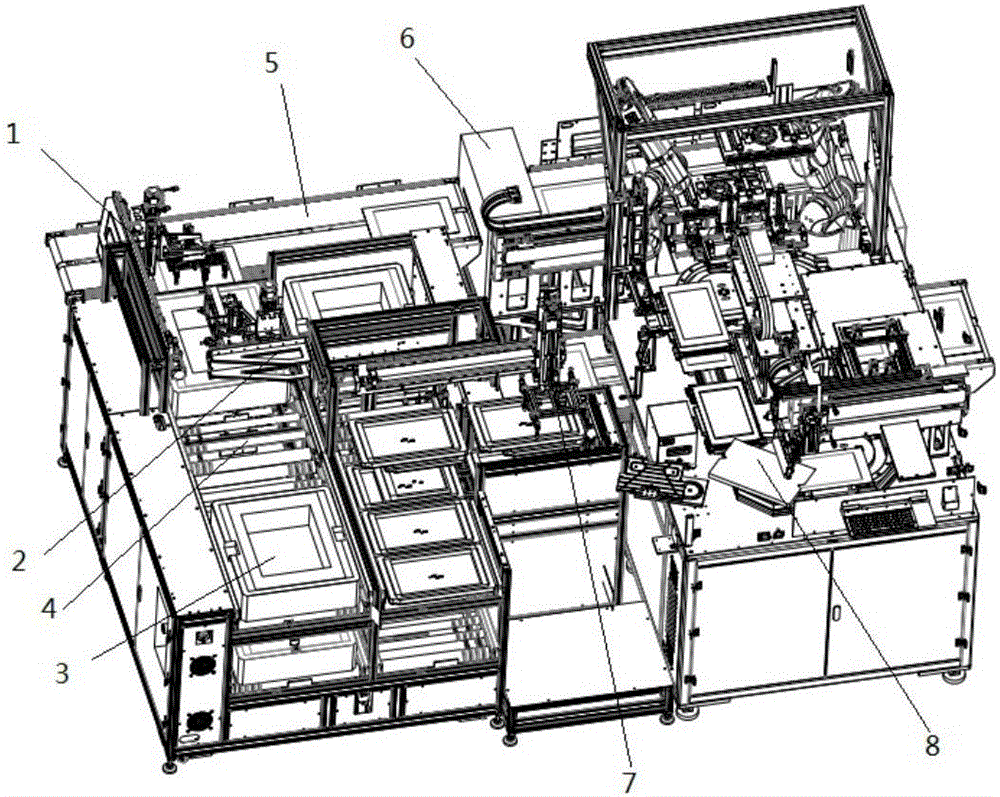

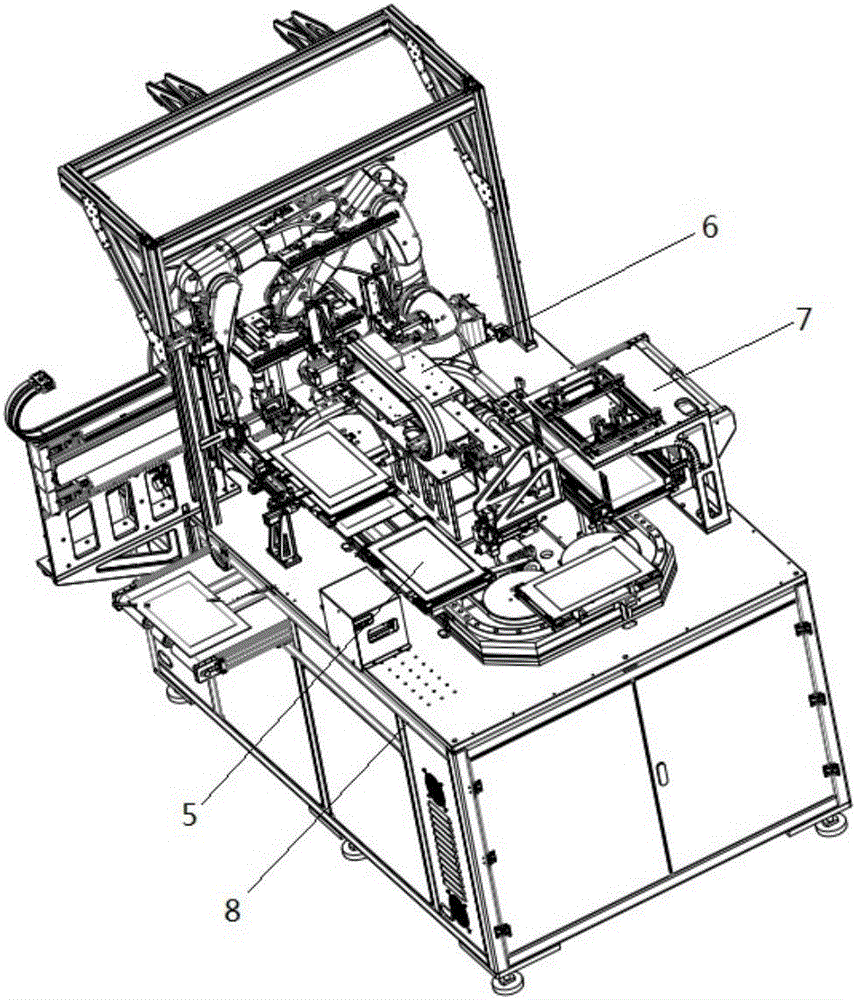

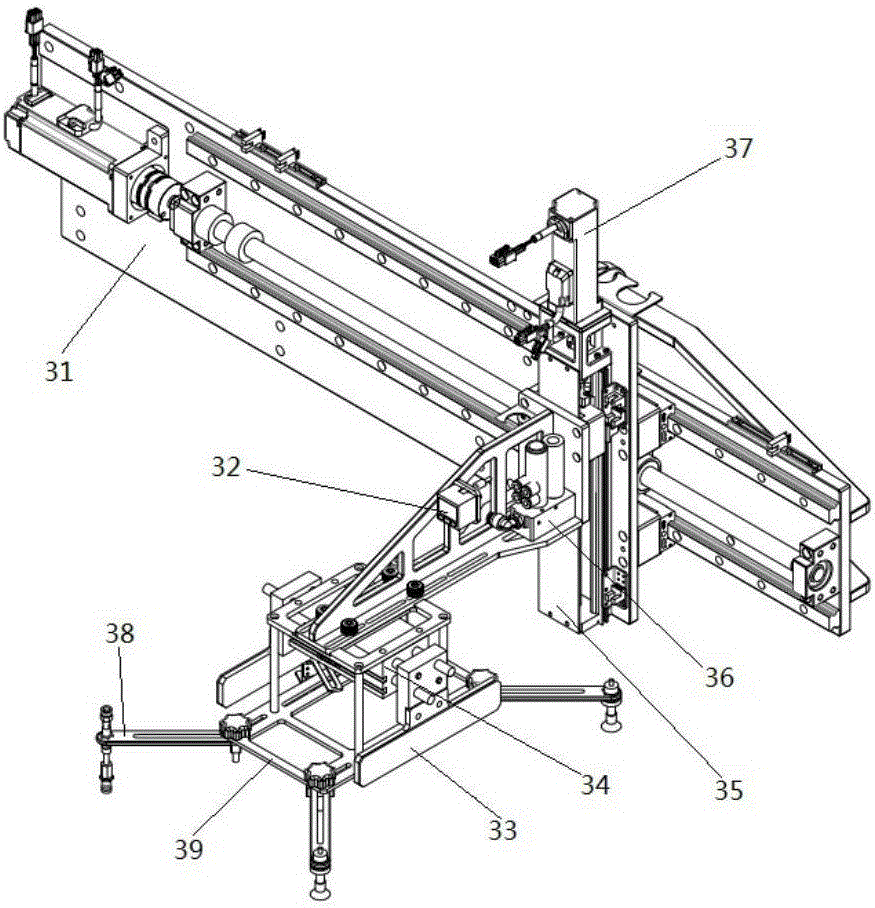

[0050] Such as figure 1 As shown, this embodiment discloses a NOTE unmanned automated production line, including a feeding mechanism and an automatic association mechanism 8, including a drum frame 4, a panel loading and handling mechanism 1, an empty BOX return steering mechanism, and a panel BOX Handling mechanism 2, panel horizontal return elevator, panel conveying track 5, panel cleaning equipment 6; roller frame 4 includes roller tracks set up and down, of which the upper roller track is the feeding track, and the lower roller track is the BOX outflow track; panel feeding The conveying mechanism 1 is arranged on the side of the extension line of the feeding track, and cooperates with the panel conveying track. The panel feeding and conveying mechanism 1 is provided with a first grabbing component for grabbing the panel. The first grabbing component is used to move the panel from Grab the steering in the panel BOX and place it on the panel conveying track;

[0051] The em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com