Processing method of PCB (printed circuit board) laminate realizing uniform edge gumming, laminate and PCB

A processing method and technology for laminates, applied in the field of laminates and PCB boards, can solve the problems of insufficient glue flow in the insulation area of the core board frame, extremely high requirements for lamination parameters, and increased production processes, so as to overcome the lack of glue flow and pressure. Combine foaming, ensure product quality stability, and overcome the effects of numerous production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

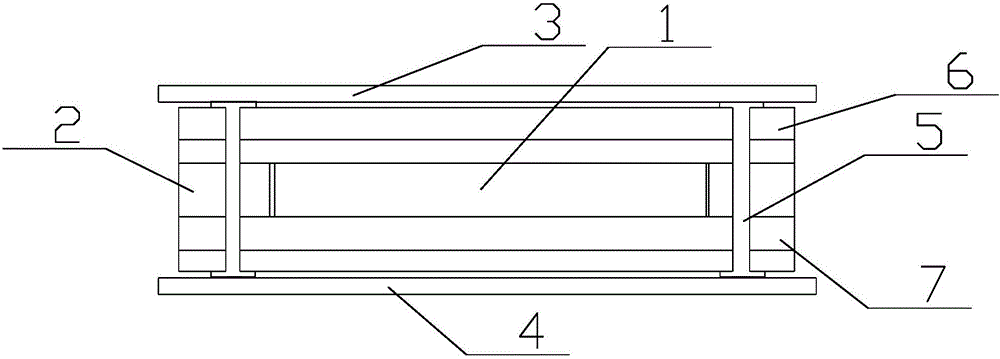

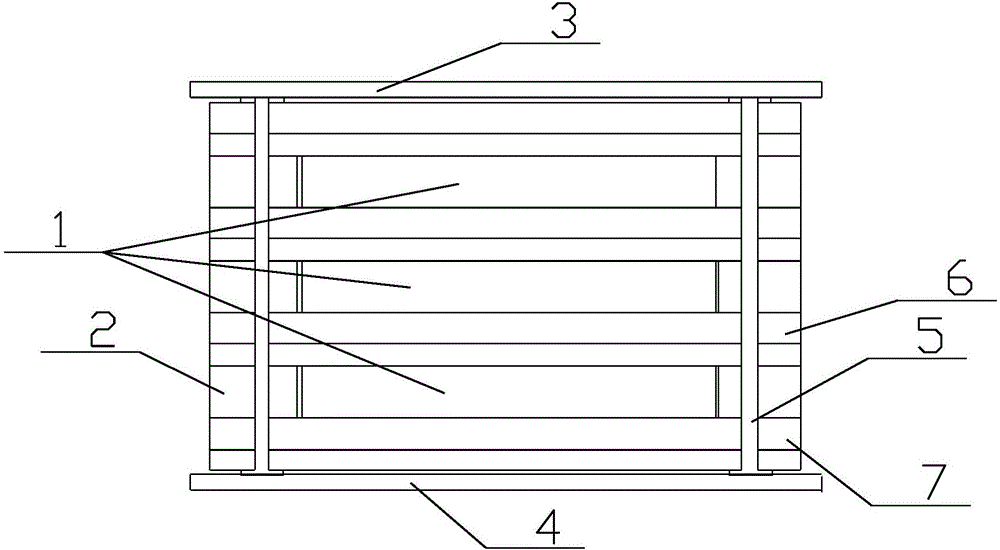

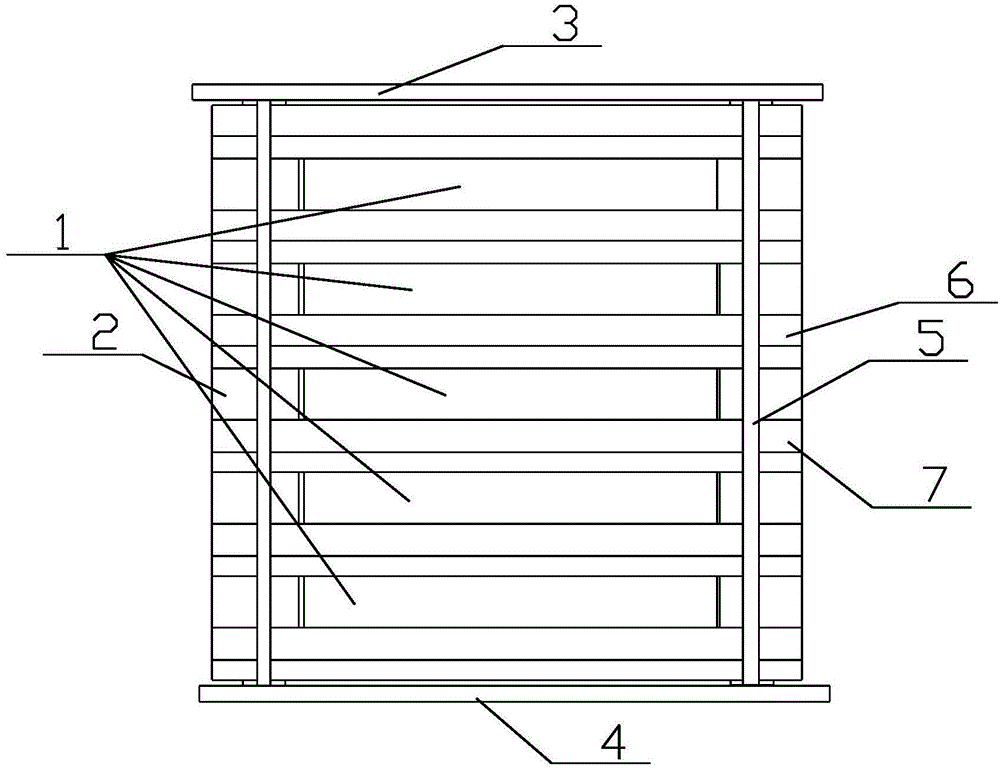

[0039] Such as Figure 1-7 As shown in the figure, a PCB laminate with uniform glue flow at the edge of the board includes a copper-based unit, an upper copper foil 3 and a lower copper foil 4, the copper-based unit is located between the upper copper foil 3 and the lower copper foil 4, and the upper copper-based unit , and the lower surface are closely attached to the upper copper foil 3 and the lower copper foil 4 respectively.

[0040] There are multiple copper-based units, and each copper-based unit is composed of a copper-based core board 1, an FR-4 outer frame 2, an upper insulating sheet 6 and a lower insulating sheet 7, and the copper-based core board 1 is placed on the FR-4 outer frame 2 Inside, the upper insulating sheet 6 and the lower insulating sheet 7 clamp the copper-based core board 1 and the FR-4 outer frame 2 in the middle, and stick to each other.

[0041] The copper-based core board 1 and the FR-4 outer frame 2 match each other, and the concave part 11 of ...

Embodiment 2

[0046] A method for processing a PCB laminate with uniform edge flow glue in Embodiment 1, comprising the following steps:

[0047] (1) FR-4 frame production.

[0048] ① Take FR-4 epoxy board, the thickness of the board is 0.05-0.1mm smaller than the thickness of the copper-based core board.

[0049] ② Drill positioning holes and rivet holes.

[0050] ③ Gong frame, the frame out of the gong fits just outside the copper-based core board and fits closely.

[0051] (2) Take the copper-based core board, and embed the copper-based core board into the FR-4 outer frame produced in step (1).

[0052] (3) Riveting and prefolding

[0053] Take the 2116 high-glue PP board and copper foil, stack the lower copper foil, 2116 high-glue PP board, copper-based core board with FR-4 outer frame, 2116 high-glue PP board, upper copper foil from bottom to top, and then Riveting into laminates with rivets.

[0054] (4) Pressure plate. The riveted laminate is pressed, and the pressed plate is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com