A high-efficiency pad printing machine with automatic material receiving function

An automatic material receiving and printing machine technology, applied to printing machines, rotary printing machines, screen printing machines, etc., can solve problems such as difficulties in automatic production, messy products, and irregular shapes, so as to shorten waiting time and ensure transfer Printing quality, preventing blurring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

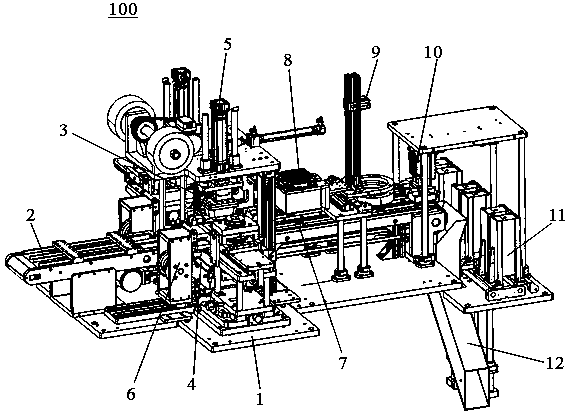

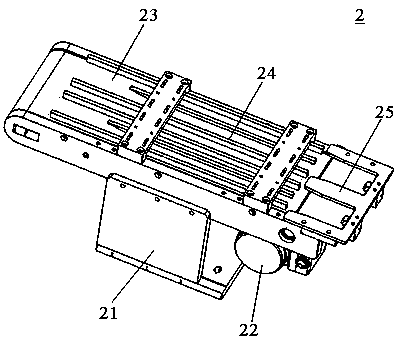

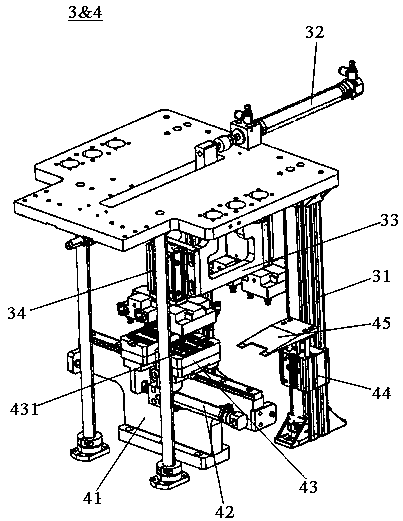

[0038] Please refer to Figure 1-Figure 7 , the present embodiment is a high-efficiency pad printing machine 100 with automatic material receiving function, which includes a machine platform 1, a feeding conveying unit 2 fixed on the machine platform 1, a feeding adsorption unit 3 docked with the feeding conveying unit 2, The distributing unit 4 located below the feeding and absorbing unit 3, the two pad printing assemblies 5 symmetrically arranged on both sides of the feeding and absorbing unit 3, the glue cleaning head assembly 6 located next to the pad printing assembly 5, and the feeding and absorbing unit 3 The docked material conveying unit 7, the drying unit 8 located above the material conveying unit 7, the detection unit 9 located downstream of the drying unit 8, the blanking adsorption unit 10 docked with the material conveying unit 7, and the blanking adsorption unit 10 docked The receiving device 11. A waste material collection box 12 is arranged at the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com