Liquid crystal display screen liquid leakage transmission detection equipment and working method thereof

A technology of liquid crystal display and transmission detection, which is applied in the direction of conveyor objects, transportation and packaging, optics, etc., to achieve the effect of convenient use and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

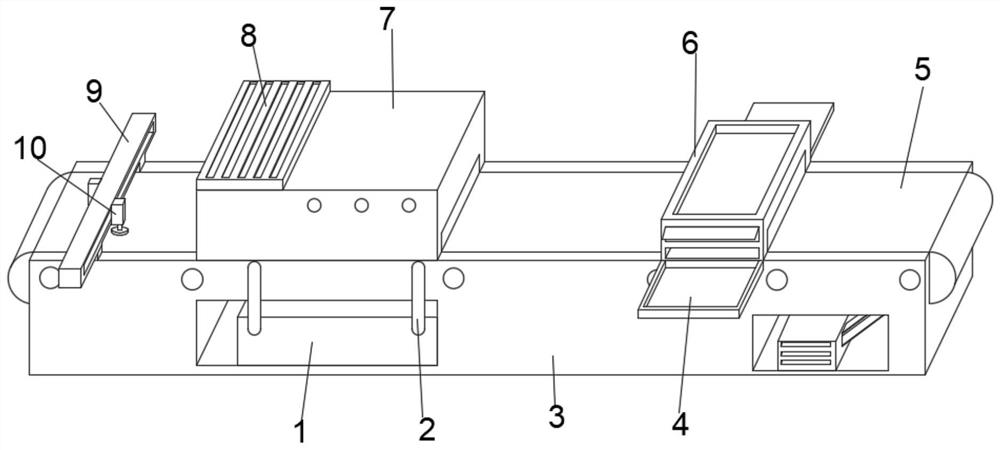

Embodiment 1

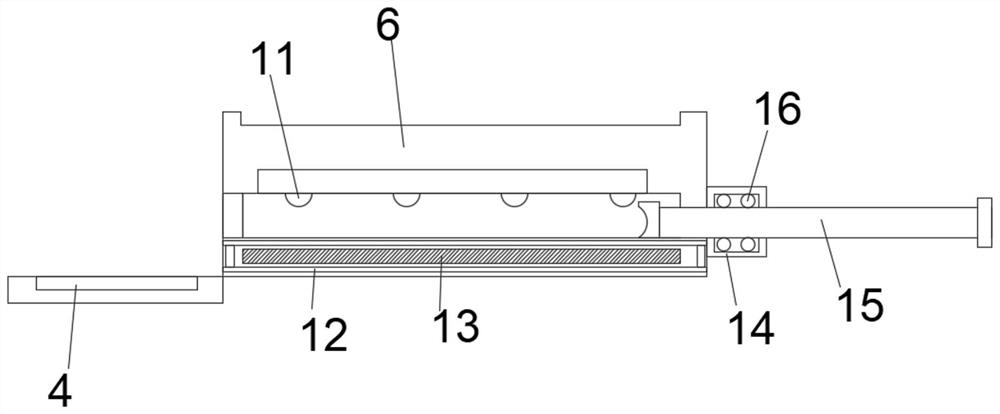

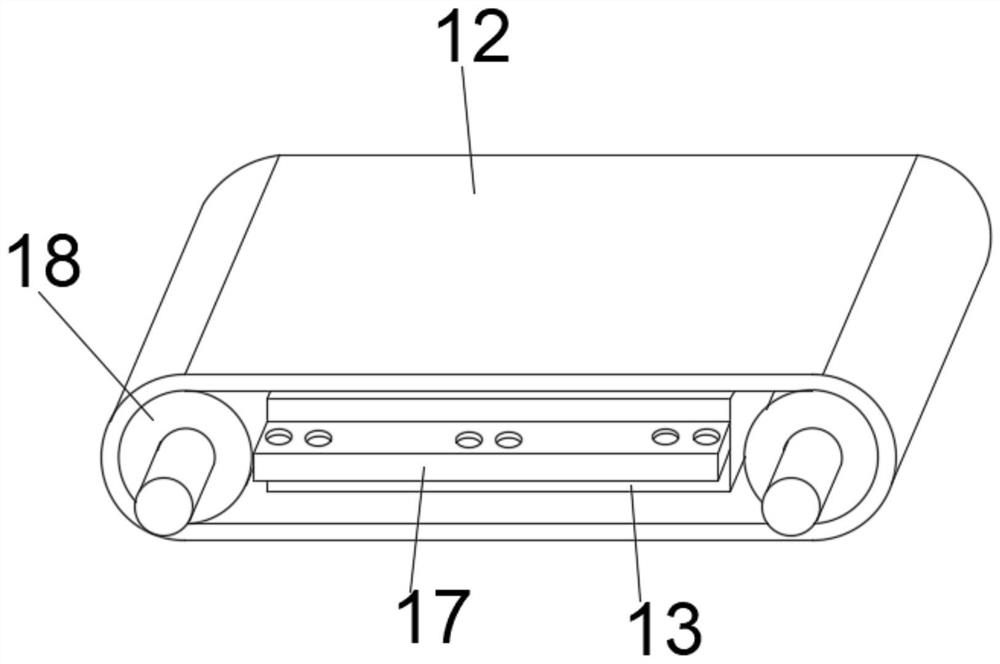

[0036] The inner lower part of the sorting box 6 is movably equipped with a second conveyor belt 12, and the middle part of the second conveyor belt 12 is provided with a light-emitting board 13, the second conveyor belt 12 is made of transparent plastic material, and the side of the light-emitting board 13 is provided with a fixed card. Bar 17, two groups of drive rollers 18 are sleeved on the inner side of the second conveyor belt 12, and the inside of the sorting box 6 is fixedly installed with a camera 11 close to the top of the second conveyor belt 12, and the liquid crystal display is transmitted to the sorting box through the first conveyor belt 5 On the second conveyer belt 12 in 6, by lighting the luminescent plate 13, the light emitted by the luminescent plate 13 is irradiated on the liquid crystal display screen through the second conveyer belt 12. When the liquid crystal display screen leaks, the irradiated area will display For different colors, use the camera 11 t...

Embodiment 2

[0040] The both sides outer surface of material receiving frame 9 is all movably installed with taking material assembly 10, and the inboard of material receiving frame 9 is provided with two groups of transverse chute 22, and the bottom of material receiving frame 9 is fixedly installed with two groups of support columns 24, and material receiving The rack 9 and the reclaiming assembly 10 are movably connected through the transverse chute 22, and the support column 24 plays a role in fixing the installation of the receiving rack 9. The retrieving assembly 10 can identify the position of the screen through the lens assembly and cooperate with the system to monitor the screen. Receiving grab operation.

[0041] The material retrieving assembly 10 includes a movable clamp 25, a first cylinder 26 and a second cylinder 27, the first cylinder 26 is fixedly installed on one side of the second cylinder 27, and the movable clamp 25 is fixedly installed on the other side of the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com