Automatic cutting point device and method

A point and cutting technology, applied in the cutting of textile materials, textile and papermaking, metal processing, etc., can solve the problem of slow work efficiency, and achieve the effect of high production efficiency, improved production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

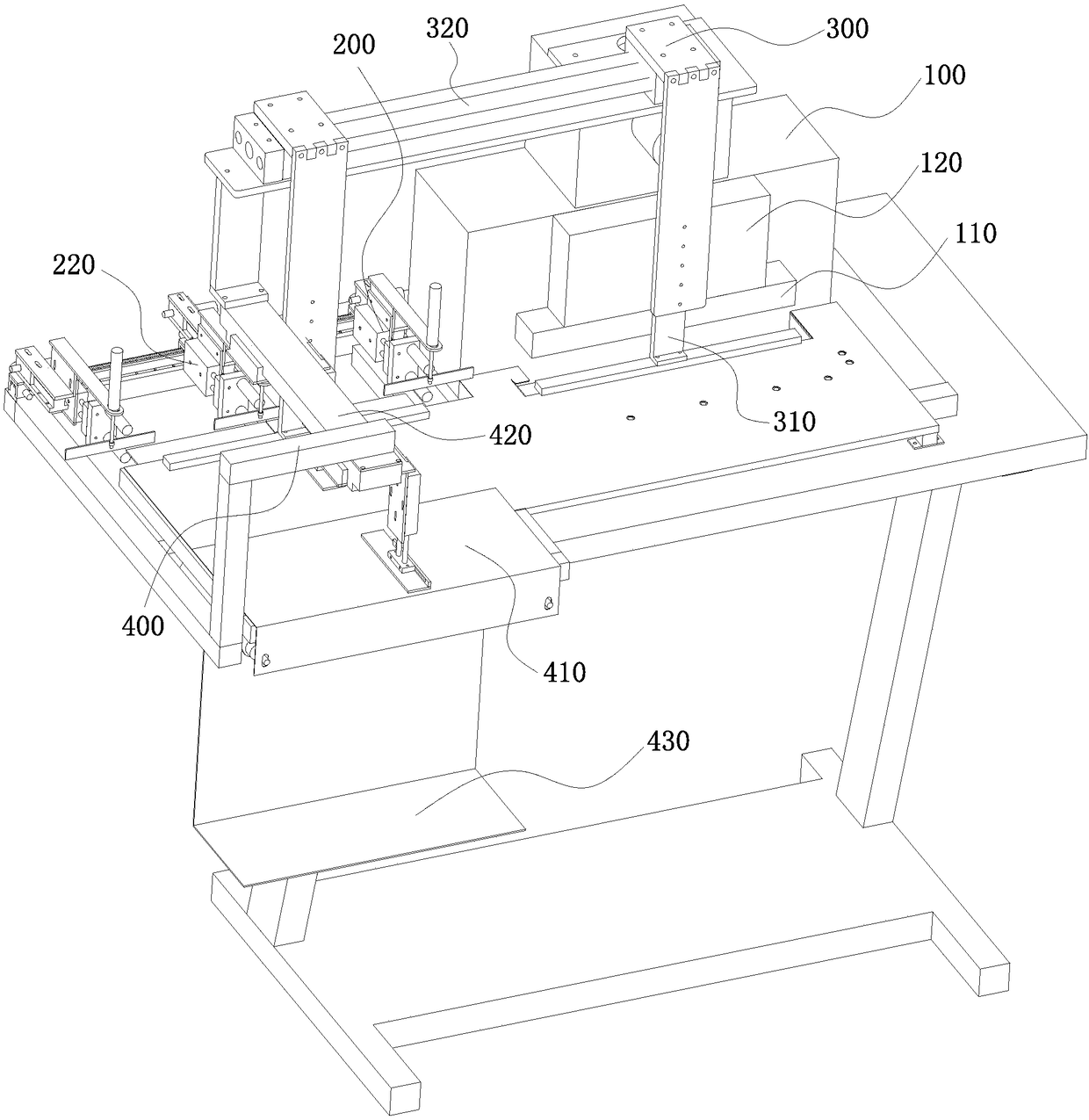

[0050] An automatic cutting point device, such as figure 1 As shown, it includes: a cutting mechanism 100 , a point mechanism 200 , a feeding mechanism 300 and a receiving mechanism 400 .

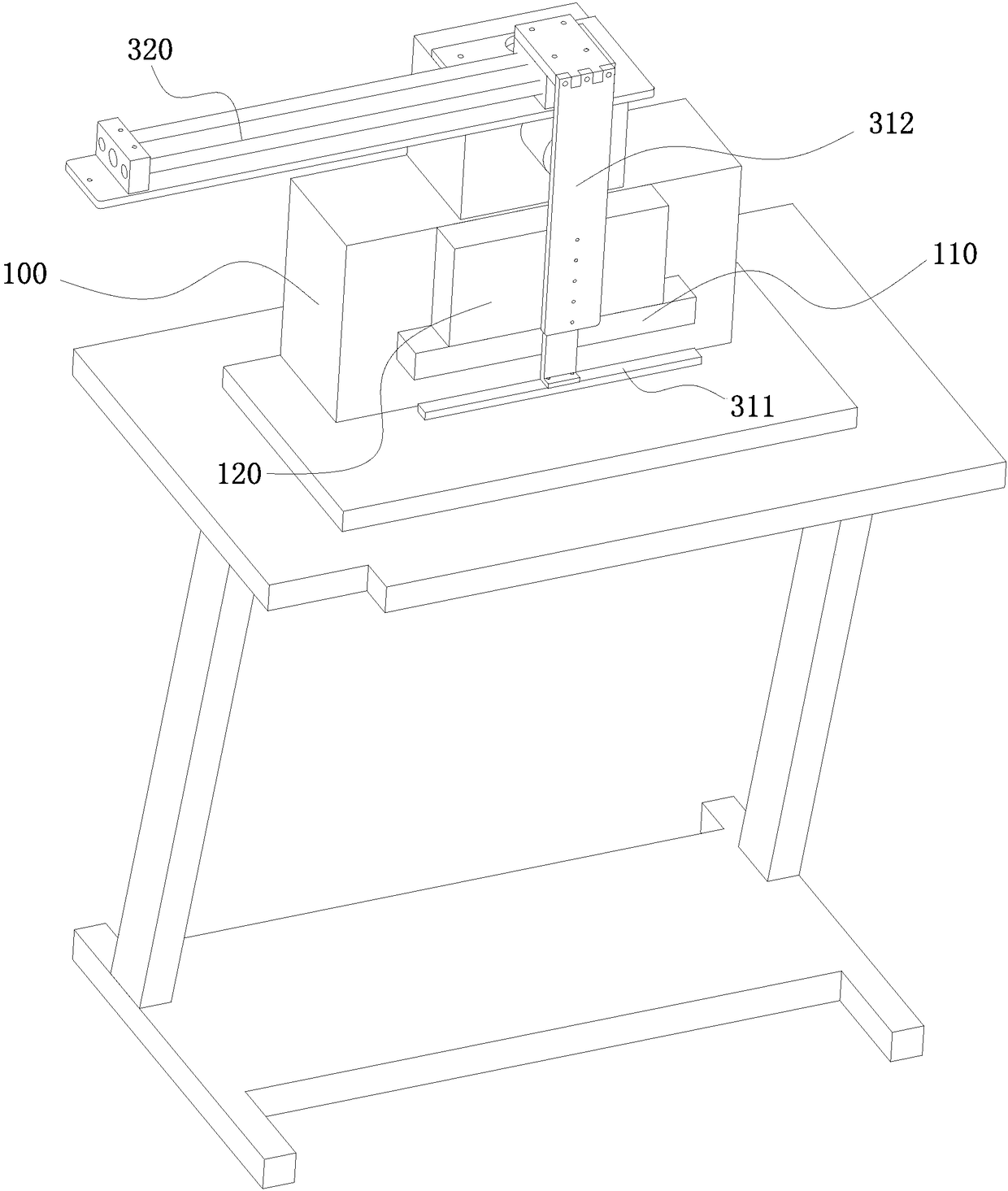

[0051] Such as image 3 As shown, the cutting mechanism 100 includes a cutting piece 110 and a cutting driving mechanism 120, the cutting piece 110 has a blade for cutting, and the cutting driving mechanism 120 drives the cutting piece 110 performs a cutting movement.

[0052] In this embodiment, the cutting mechanism 100 is built with a collar cutting machine as a carrier, and the above-mentioned cutting driving mechanism adopts a cylinder with compressed air as the power source, and the compressed air is used as the power source, and the electromagnetic valve changes the transmission direction of the compressed air. Drive the cylinder to move to drive the cutting piece to complete the function of the incision, which has a better cutting effect.

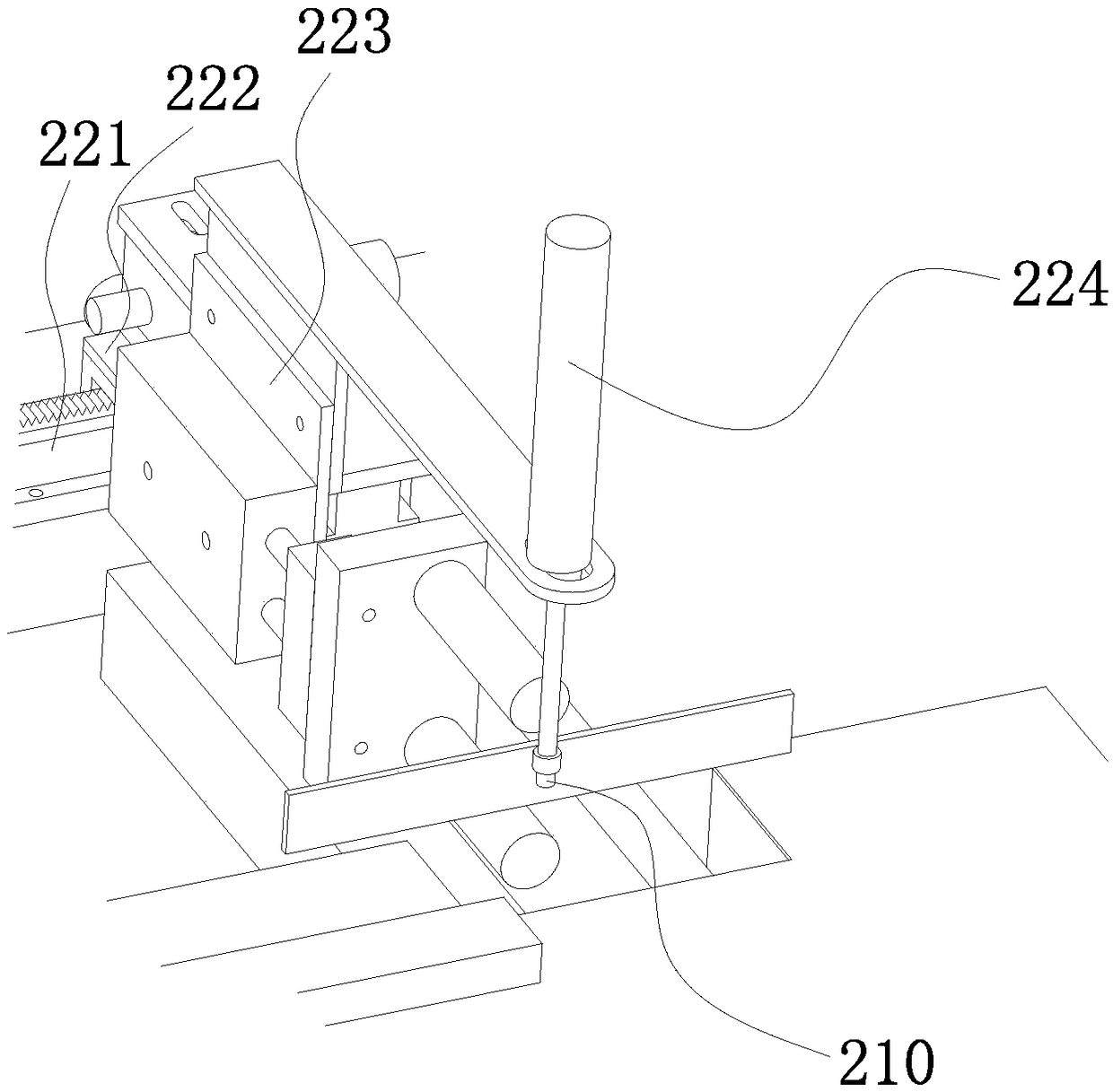

[0053] Such as figure 2 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com