Bend pipe winding disc with rolling function

A winding coil and pipe bending technology, which is applied in the field of curved pipe winding coils, can solve the problems of rolling on the surface of the anti-corrosion tape, poor effect of air bubbles, and reducing labor intensity, so as to improve the efficiency of winding operations, simple structure, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

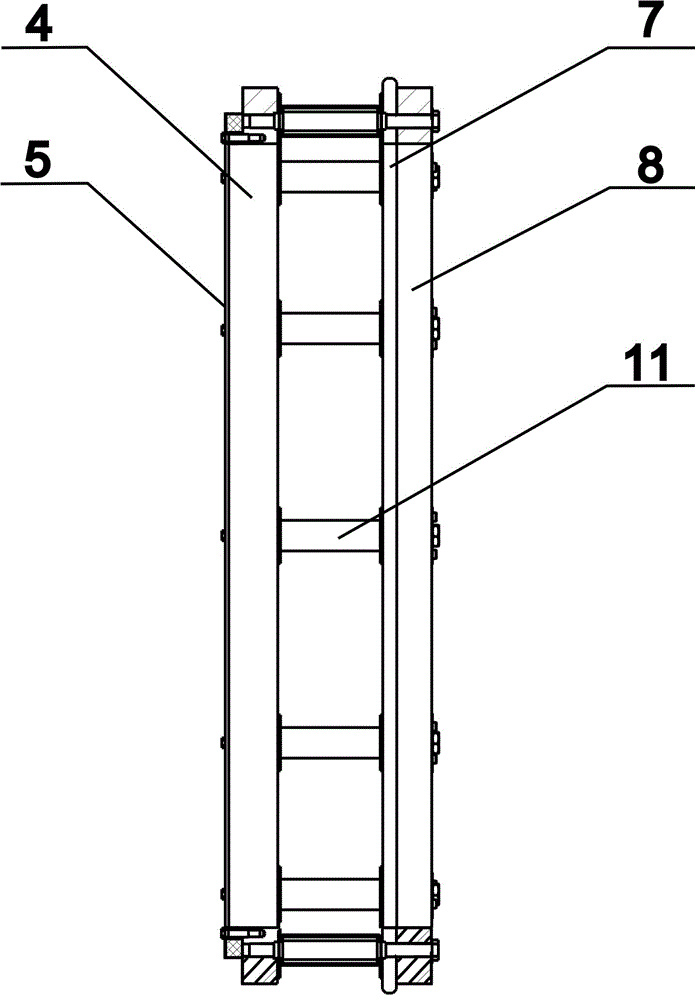

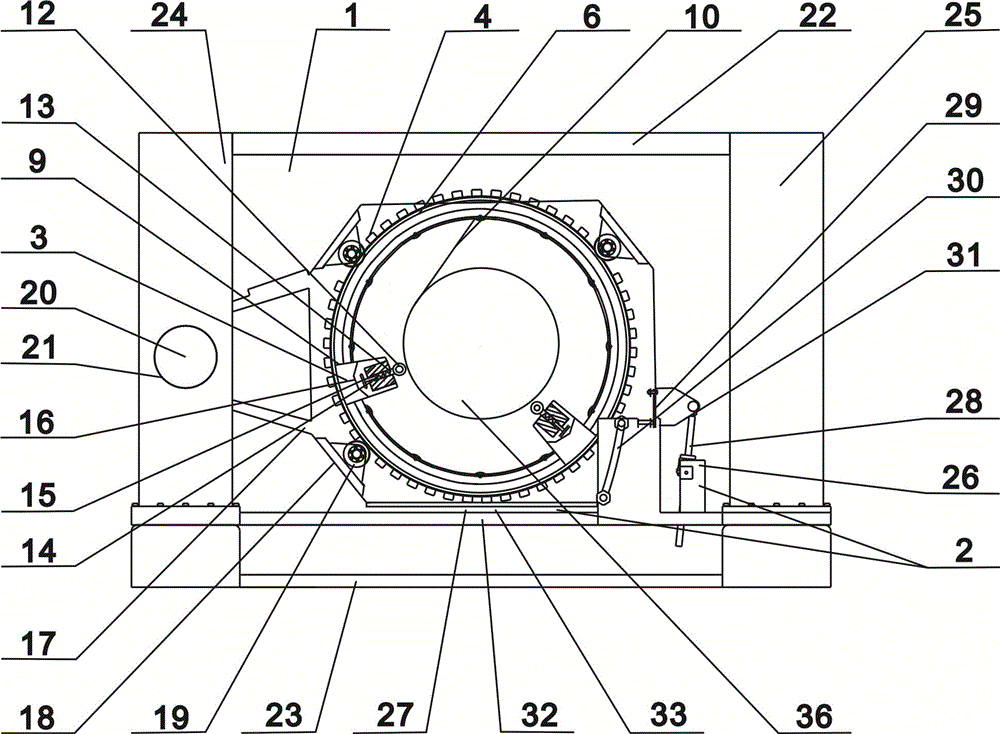

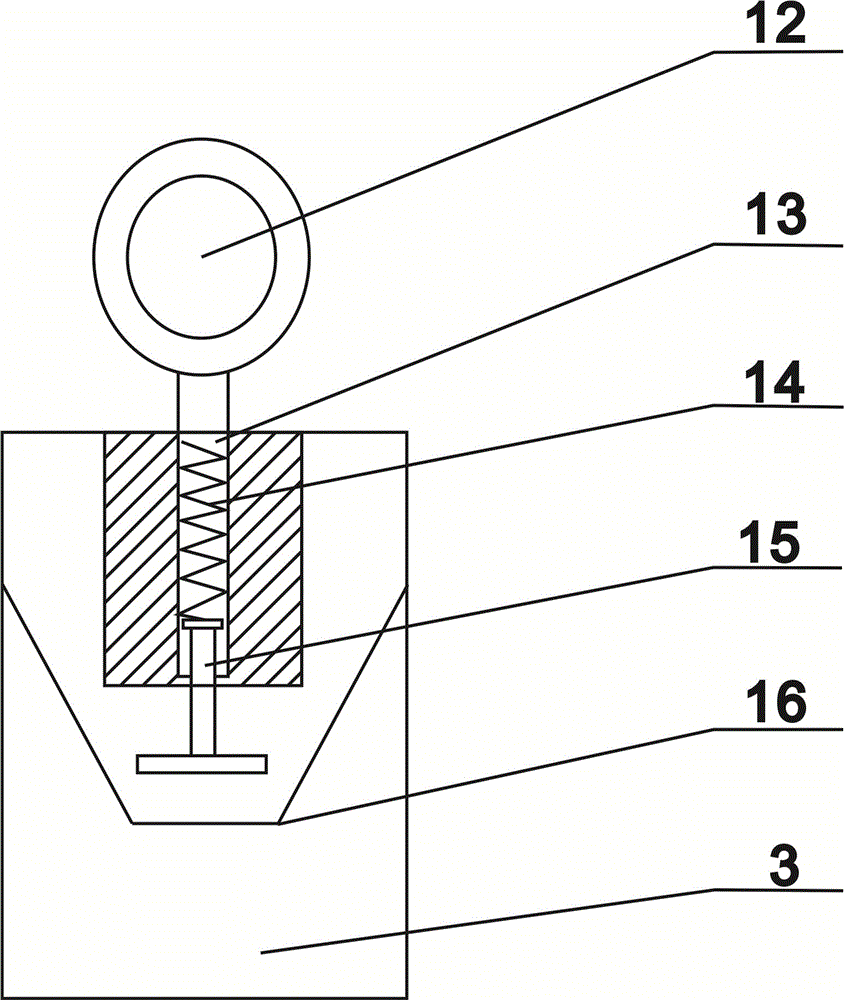

[0024] As shown in the figure, a curved pipe winding disc with rolling function includes a winding disc 1, an aligning device 2, and a rolling device 3; the winding disc 1 is composed of a gear 4, a gear side plate 5, a mounting base plate 6, a brush Side plate 7, brush ring 8, connecting plate 9, winding tape 10, mandrel 11, bracket 17, support plate 18, support roller 19, fixed shaft 20, shaft hole 21, upper cover plate 22, lower bottom plate 23, left Composed of column 24 and right column 25, gear 4 is arranged on the right side of gear side plate 5, and is fixedly connected with gear side plate 5; brush side plate 7 is arranged on the right side of gear 4, on the right side of brush side plate 7 A brush ring 8 is arranged on the side, and a mandrel 11 is arranged at the middle position between the gear 4 and the brus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com