A kind of laser cutting method of tempered glass

A tempered glass, laser cutting technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of no longer cutting or opening, to prevent edge chipping and overall cracking defects, fast speed, cutting good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

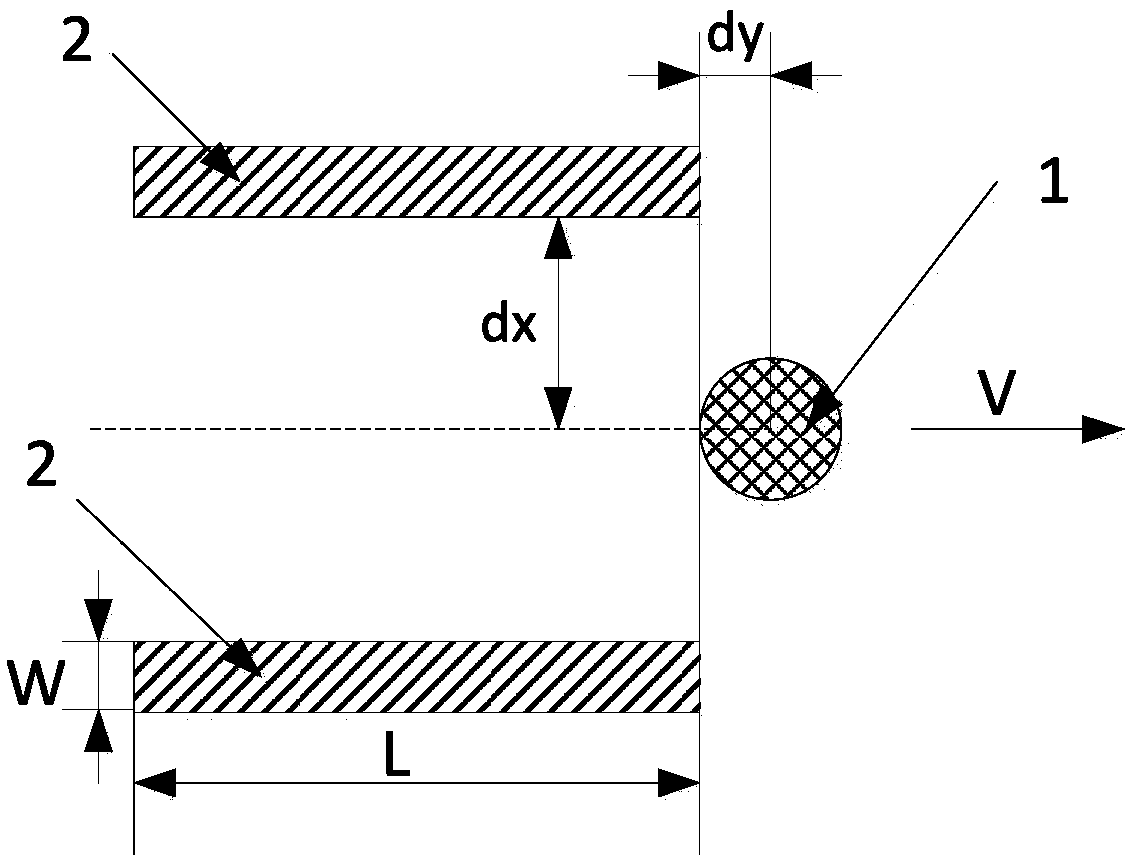

[0028] Assuming that the cutting speed along the path to be cut of the tempered glass is a vector V, the value of the vector V is the cutting speed value, and the direction of the vector V is the cutting direction.

[0029] The invention provides a laser cutting method for tempered glass, which specifically includes the following steps:

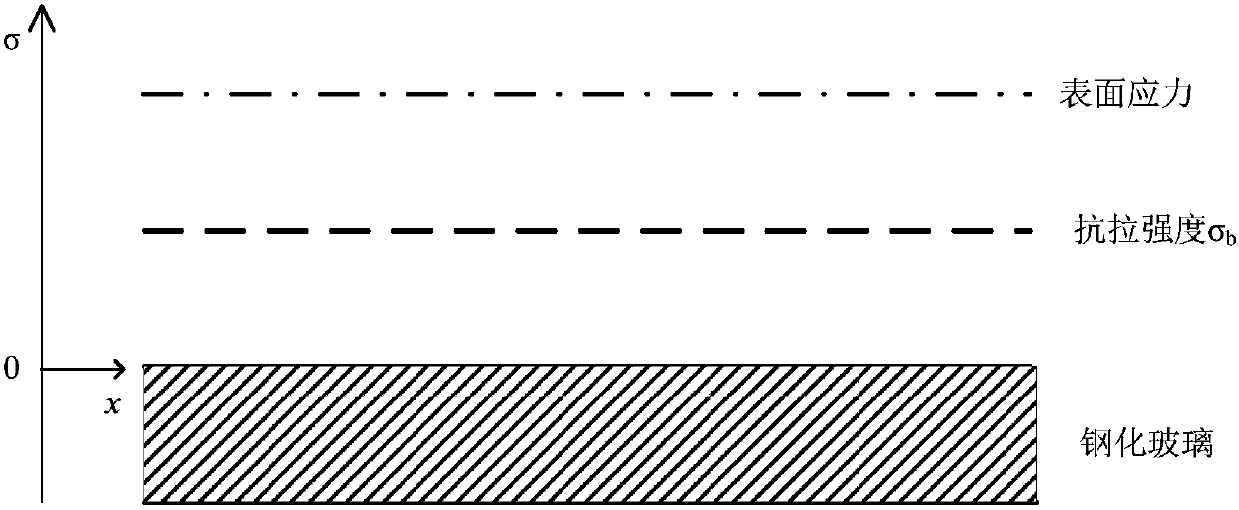

[0030] (1) if figure 1 As shown, the laser cutting beam assisted by bilateral cooling jets is arranged at the starting point of the tempered glass to be cut. The included angle (incident angle less than 45 degrees) is incident on the surface of the tempered glass, focusing on the surface of the tempered glass or having a certain amount of defocus, that is, forming a laser spot with a diameter of R on the surface of the tempered glass. In order to obtain a fine cutting slit width, R is required less...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com