Glass incrustation cleanser and preparing method thereof

A cleaning agent and scale technology, which is applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of difficulty in removing old scale on glass or other hard surfaces, and water droplets on the glass surface. The effect of improving the hydrophilic and softening water performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

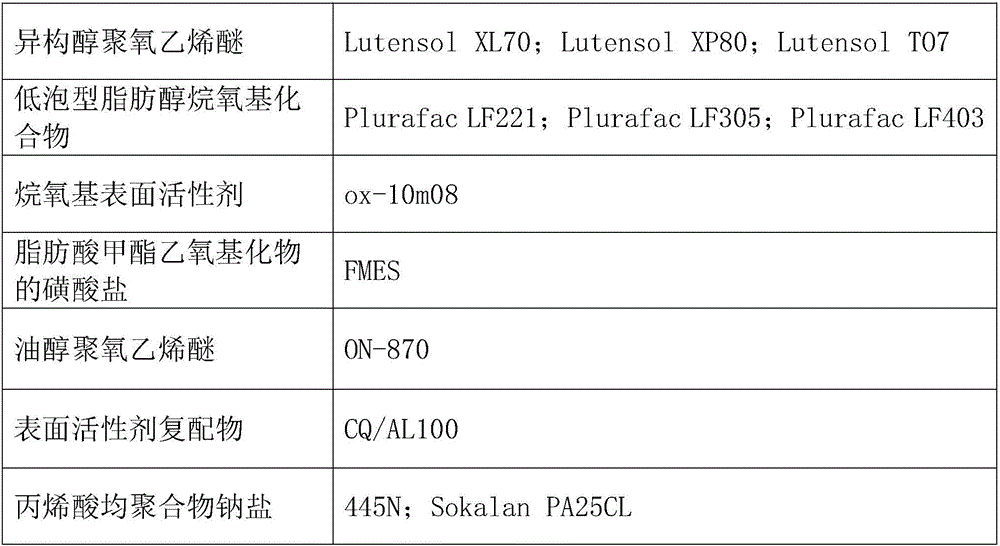

[0033] Example 1: Mix isomeric alcohol polyoxyethylene ether (Lutensol XL70) and low-foaming fatty alcohol alkoxylate (Plurafac LF221) in a ratio of 3:2 to prepare 5 parts of surfactant, ammonium bifluoride 5 parts as fluoride, phosphoric acid and citric acid are mixed according to the weight ratio of 2:1 to make 15 parts of weak acid, 2 parts of acrylic acid homopolymer sodium salt (445N), 5 parts of borax, and 10 parts of isopropanol as solvent , 58 parts of demineralized water at 50°C, set aside.

[0034] Add demineralized water at 50°C to the container, add fluoride and borax to the container, add weak acid after the fluoride and borax are completely dissolved, and stir until the solution is transparent.

[0035] Add surfactant and acrylic acid homopolymer sodium salt to the container in sequence, and stir until the acrylic acid homopolymer sodium salt is completely dissolved to obtain solution a.

[0036] After the temperature of solution a is lower than 40°C, add solven...

Embodiment 2

[0037] Embodiment 2: get isomerized alcohol polyoxyethylene ether (Lutensol XL70) and alkoxyl surfactant (ox-10m08) and mix by the weight ratio of 4:3 and make 7 parts of surfactant, hydrofluoric acid and Sodium fluorosilicate was mixed in the proportion of 20:1 to obtain 10.5 parts of fluoride, glacial acetic acid and citric acid were mixed in the proportion of 3:2 to obtain 25 parts of weak acid, acrylic acid homopolymer sodium salt (445N ) 1 part, 3 parts of borax, 5 parts of ethanol as a solvent, 48.5 parts of demineralized water at 50°C, set aside.

[0038] Add demineralized water at 50°C to the container, add fluoride and borax to the container, add weak acid after the fluoride and borax are completely dissolved, and stir until the solution is transparent.

[0039] Add surfactant and acrylic acid homopolymer sodium salt to the container in sequence, and stir until the acrylic acid homopolymer sodium salt is completely dissolved to obtain solution a.

[0040] After the t...

Embodiment 3

[0041] Example 3: Take alkoxy surfactant (ox-10m08) and surfactant compound (CQ / AL100) and mix according to the weight ratio of 3:5 to prepare 8 parts of surfactant, sodium bifluoride and fluorine Sodium silicate was mixed at a ratio of 2:1 to obtain 1.5 parts of fluoride, oxalic acid and citric acid were mixed at a ratio of 1:2 to obtain 15 parts of weak acid, and acrylic acid homopolymer sodium salt (445N)2 1 part, 1 part of borax, 10 parts of ethanol as a solvent, 62.5 parts of demineralized water at 50°C, set aside.

[0042] Add demineralized water at 50°C to the container, add fluoride and borax to the container, add weak acid after the fluoride and borax are completely dissolved, and stir until the solution is transparent.

[0043] Add surfactant and acrylic acid homopolymer sodium salt to the container in sequence, and stir until the acrylic acid homopolymer sodium salt is completely dissolved to obtain solution a.

[0044] After the temperature of solution a is lower ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap