Mesh-belt built-in hot-air cyclic heating tempering furnace and heating method thereof

A hot air circulation, mesh belt technology, applied in heat treatment furnaces, furnaces, furnace types, etc., can solve the problems of uneven temperature distribution, increased cost, increased failure rate, etc., and achieves easy assembly, disassembly, maintenance, maintenance, and low noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be further described in detail below with reference to the drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the principles of the present invention, and are not intended to limit the present invention.

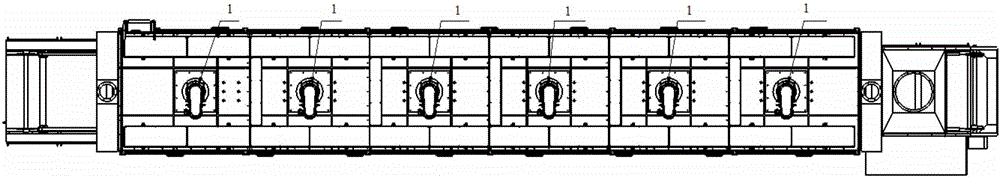

[0030] like figure 1 It is a tempering furnace structure using a traditional stirring and uniform temperature system. A 12-meter-long furnace body requires six sets of mixing systems 1, which increases the manufacturing cost, the failure rate, and the user's use cost; If the exchange is not uniform, it will cause the temperature here to be high or low.

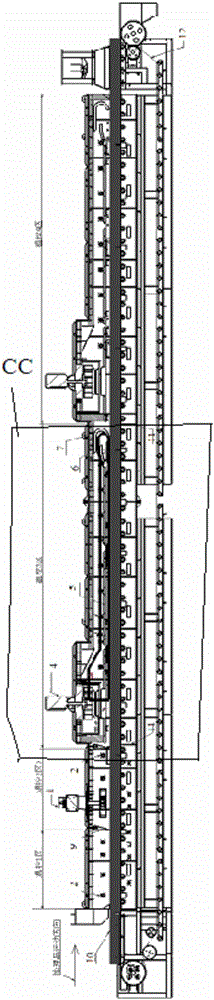

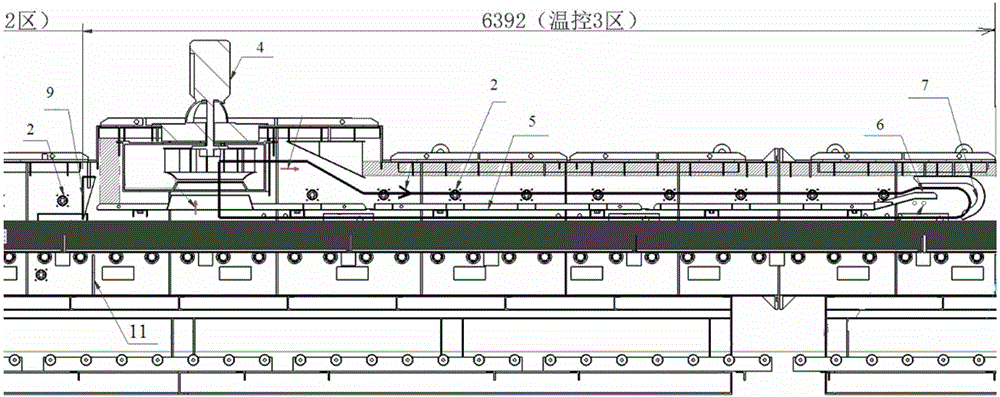

[0031] like figure 2 It is a tempering furnace structure heated by built-in hot air circulation. The mesh belt type built-in hot air circulation heating tempering furnace includes a hot air inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com