Heat treatment improvement process of wave spring for bearing

A technology of wave spring and process, which is applied in the field of spring processing technology and heat treatment improvement process of wave spring for bearings. It can solve the problems of unstable anti-decarburization protection, bonding and oxidation of carburizing agent and workpiece, and achieve improved quenching protection. method, prevention of oxidative decarburization, and the effect of optimizing process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

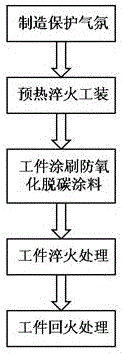

Image

Examples

Embodiment

[0018] The specific processing method is as follows:

[0019] a) To create a protective atmosphere, first heat the box-type resistance furnace to 850°C, then add charcoal to the furnace and keep the temperature constant for 20 minutes, so that the charcoal will react with the oxygen in the furnace to generate carbon dioxide or carbon monoxide gas, thereby reducing the amount of gas in the process of workpiece processing Oxidative decarburization trend.

[0020] b) Preheat the quenching tool, put the quenching tool in the box-type resistance furnace to keep the temperature for 30 minutes, then take it out, and wait for the workpiece to be installed.

[0021] c) The workpiece is painted with anti-oxidation and decarburization coating, and the self-made anti-oxidation and decarburization coating is painted on the surface of the workpiece to isolate the oxygen from the surface of the workpiece during the quenching and heating process, and further reduce the tendency of oxidation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com