Acrylic-cellulose acetate fiber functional knitted fabric and knitting method

A technology of acetate blue fiber and knitted fabric, applied in knitting, weft knitting, textile and papermaking, etc., can solve the problems of short timeliness, loss, etc., and achieve the effects of improving moisture conductivity, reducing stroking friction and good warmth retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] A functional knit fabric of acetate blue fiber, the front side of the fabric is jacquard, the middle layer of polyester is closely connected, and the reverse side is made of acetate blue fiber blended yarn;

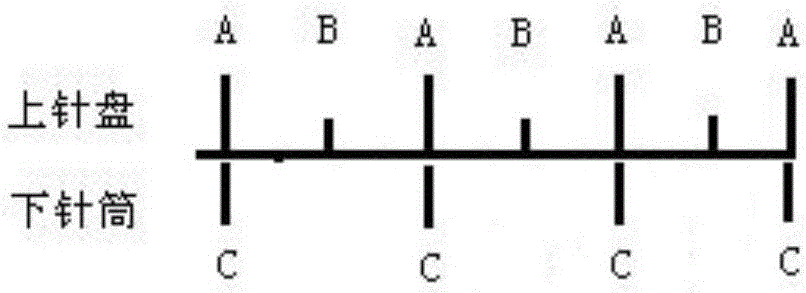

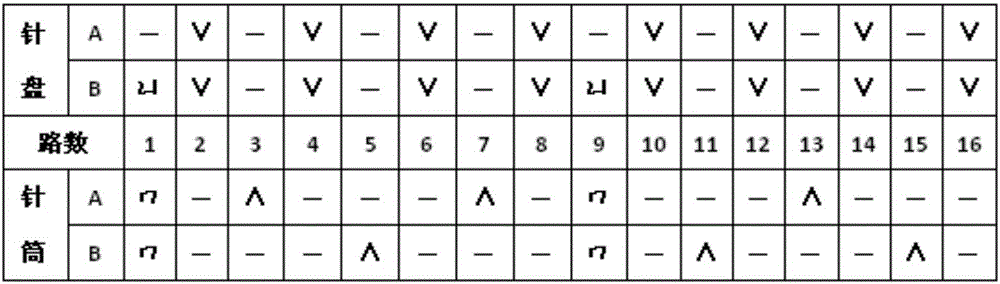

[0046] Moreover, the fabric is woven with jacquard threading combined with variable rib weave and variable flat stitch; the variable rib weave is alternately woven with acrylic-viscose blended yarn strands, cotton-nylon 6 blended yarn strands, and polyester , the variable plain stitch is woven on the dial by using acetate green fiber blended yarn, and the acetate green fiber blended yarn is acetate green-modal-Veloft blended yarn.

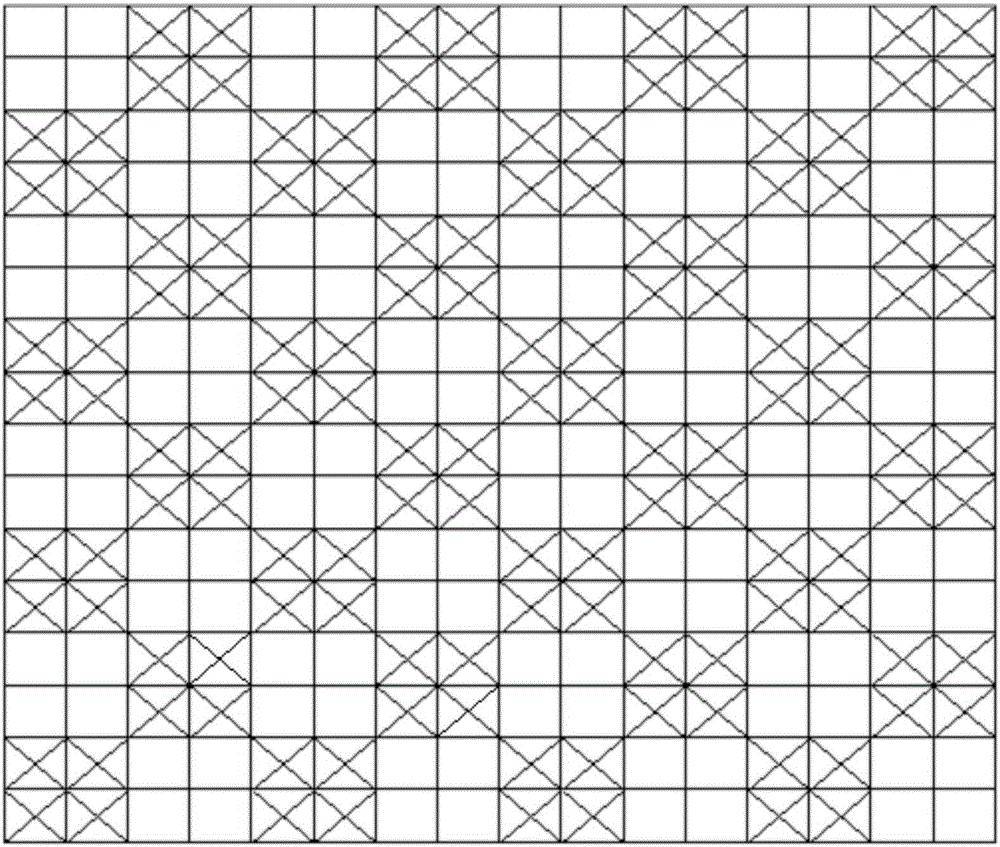

[0047] The jacquard on the front side is in the shape of zigzag corrugations, and the back side is in the shape of polka dots and horizontal stripes.

[0048] This embodiment gives full play to the functions of various fibers, and has multiple functions such as softness and comfort, anti-pilling, moisture absorption and breathability, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Barrel diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com