Explosion-proof shock-proof protecting system of cable-girder anchorage zone and manufacturing method of explosion-proof shock-proof protecting system

A protection system and anti-shock technology, applied to bridges, bridge parts, bridge construction, etc., to achieve the effects of avoiding direct collisions, good ductility, and high protection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

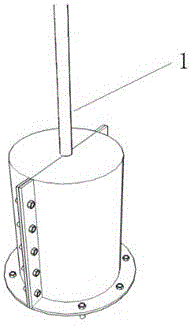

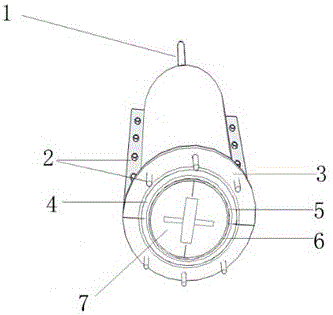

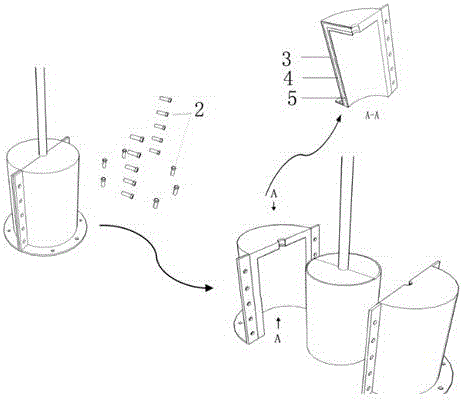

[0043] Such as Figure 1-Figure 5 As shown, an anti-explosion and anti-shock protection system for the anchorage area of a cable beam includes an α-type hemihydrate plaster mold 7, a PTFE membrane material layer 6, an inner steel plate 5, a foamed aluminum layer 4, and an outer steel plate 3. The α-type hemihydrate The gypsum mold 7 is wrapped outside the cable beam anchorage area 1, the PTFE membrane material layer 6 is wrapped around the outside of the α-type hemihydrate plaster mold 7 and the PTFE membrane material layer 6 is at least three layers, and the PTFE membrane material layer 6 is outside The inner steel plate 5, the foamed aluminum layer 4, and the outer steel plate 3 are set sequentially. On the outer side and the bottom of the outer steel plate 3, there are a plurality of high-strength bolts 2 connection holes for connecting with the bridge deck of the cable beam anchorage area 1.

[0044] The α-type hemihydrate gypsum mold 7 is composed of two symmetrical sem...

Embodiment 2

[0064] Such as Figure 1-Figure 5 As shown, an anti-explosion and anti-shock protection system for the anchorage area of a cable beam includes an α-type hemihydrate plaster mold 7, a PTFE membrane material layer 6, an inner steel plate 5, a foamed aluminum layer 4, and an outer steel plate 3. The α-type hemihydrate The gypsum mold 7 is wrapped outside the cable beam anchorage area 1, the PTFE membrane material layer 6 is wrapped around the outside of the α-type hemihydrate plaster mold 7 and the PTFE membrane material layer 6 is at least three layers, and the PTFE membrane material layer 6 is outside The inner steel plate 5, the foamed aluminum layer 4, and the outer steel plate 3 are set sequentially. On the outer side and the bottom of the outer steel plate 3, there are a plurality of high-strength bolts 2 connection holes for connecting with the bridge deck of the cable beam anchorage area 1.

[0065] The α-type hemihydrate gypsum mold 7 is composed of two symmetrical sem...

Embodiment 3

[0085] Such as Figure 1-Figure 5 As shown, an anti-explosion and anti-shock protection system for the anchorage area of a cable beam includes an α-type hemihydrate plaster mold 7, a PTFE membrane material layer 6, an inner steel plate 5, a foamed aluminum layer 4, and an outer steel plate 3. The α-type hemihydrate The gypsum mold 7 is wrapped outside the cable beam anchorage area 1, the PTFE membrane material layer 6 is wrapped around the outside of the α-type hemihydrate plaster mold 7 and the PTFE membrane material layer 6 is at least three layers, and the PTFE membrane material layer 6 is outside The inner steel plate 5, the foamed aluminum layer 4, and the outer steel plate 3 are set sequentially. On the outer side and the bottom of the outer steel plate 3, there are a plurality of high-strength bolts 2 connection holes for connecting with the bridge deck of the cable beam anchorage area 1.

[0086]The α-type hemihydrate gypsum mold 7 is composed of two symmetrical semi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com