Taper spring sleeve for prefabricated parts of underground comprehensive pipe gallery - card sleeve connection assembly device

A technology of integrated pipe gallery and assembly device, which is applied to underwater structures, water conservancy projects, artificial islands, etc. It can solve the problems of difficult guarantee of manufacturing accuracy and engineering quality, narrow space of comprehensive pipe gallery, and difficult construction environment, etc. Firm and reliable, guarantee the quality of construction, and promote the effect of factory manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

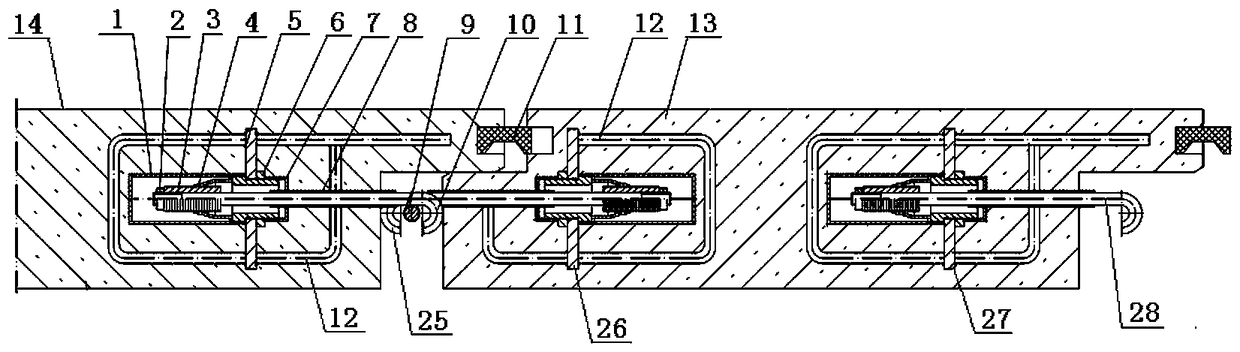

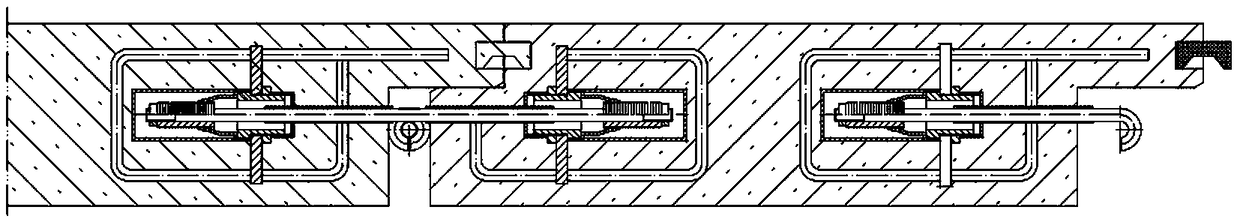

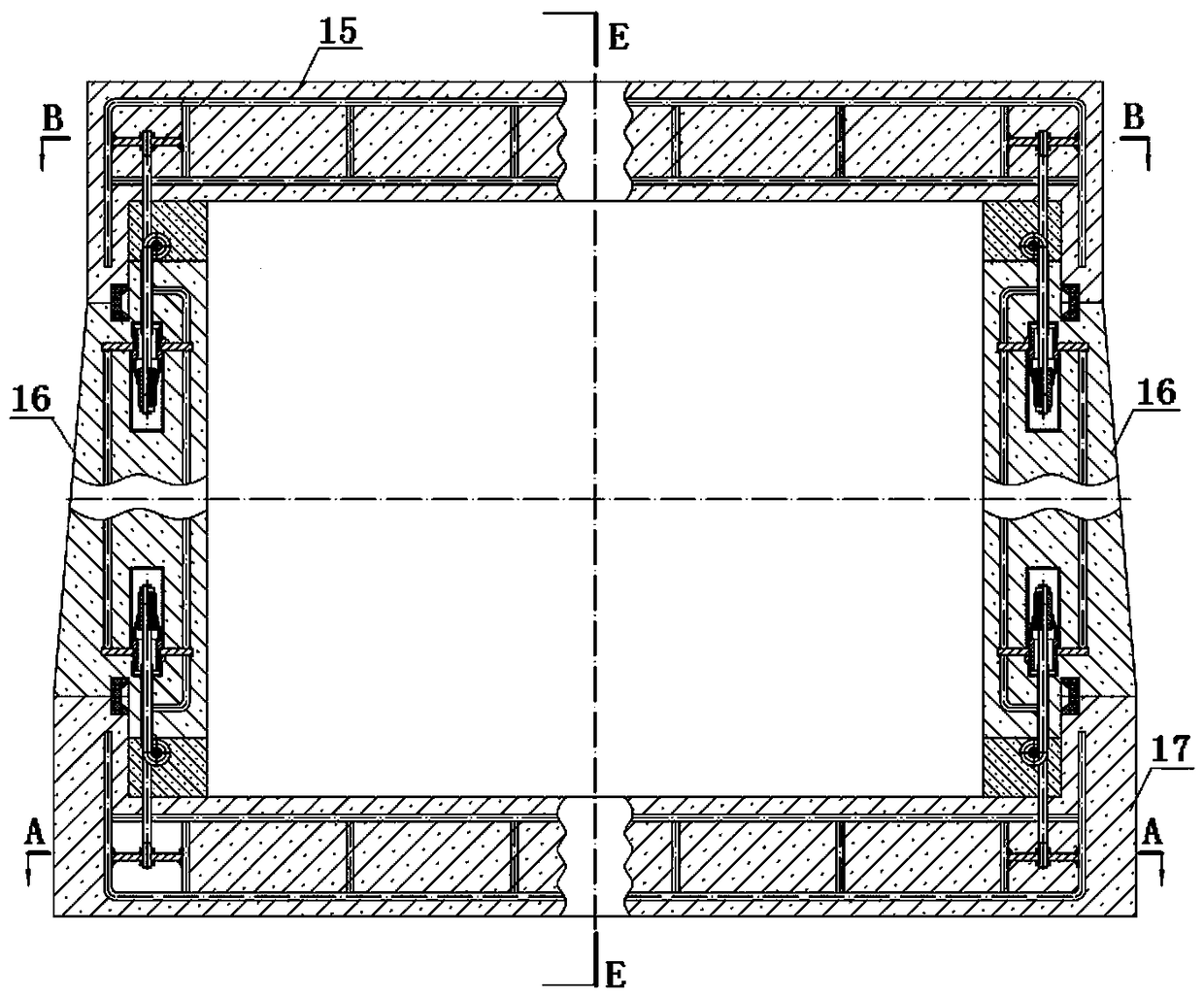

[0016] The taper spring sleeve 4 is tightly connected by the nut 6 and the steel plate 5, and the steel plate 5 and the steel bar 12 are welded into a whole; the ferrule 3 is threadedly connected with the pull rod 10, and is fastened on the pull rod 10 by the nut 2, and the semicircle hook of the pull rod 10 is opposite to the mandrel 9 hinged; the saw-shaped teeth of the ferrule 3 and the saw-shaped teeth of the tapered spring sleeve 4 bite each other; the plastic sleeve 1 is set on the tapered spring sleeve 4 and the ferrule 3 and is threadedly connected with the large end of the tapered spring sleeve. 7 sets of plastic sleeves are threaded at the 4 small ends of the tapered spring sleeves and the 4 small ends of the tapered spring sleeves. The plastic sleeve 8 is sleeved on the pull rod 10 and penetrates into the plastic sleeve 7 . The effect of plastic cover 1,7,8 is exactly to cover taper spring cover 4, ferrule 3, and pull bar 10 is isolated with concrete, and protection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com