Rotating, cutting and coring device capable of rapidly digging landmine pit in hard ground

A technology of rotary cutting and coring device, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of affecting operation efficiency, slow mining speed, inaccurate size, etc., to improve combat effectiveness, camouflage Good effect and low waste pit rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

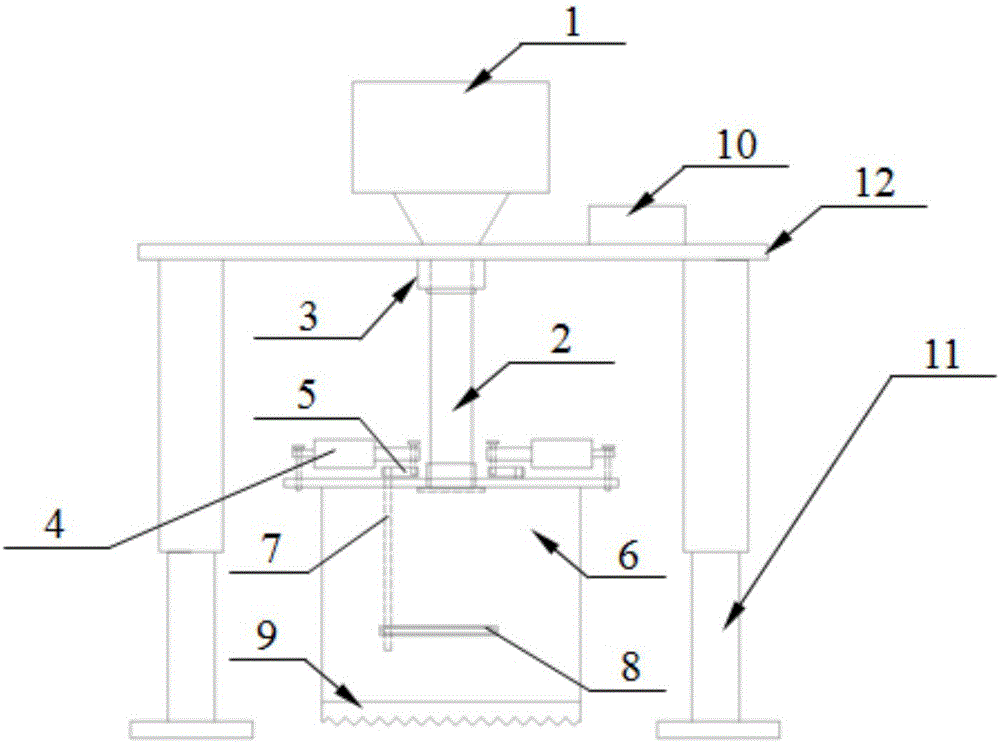

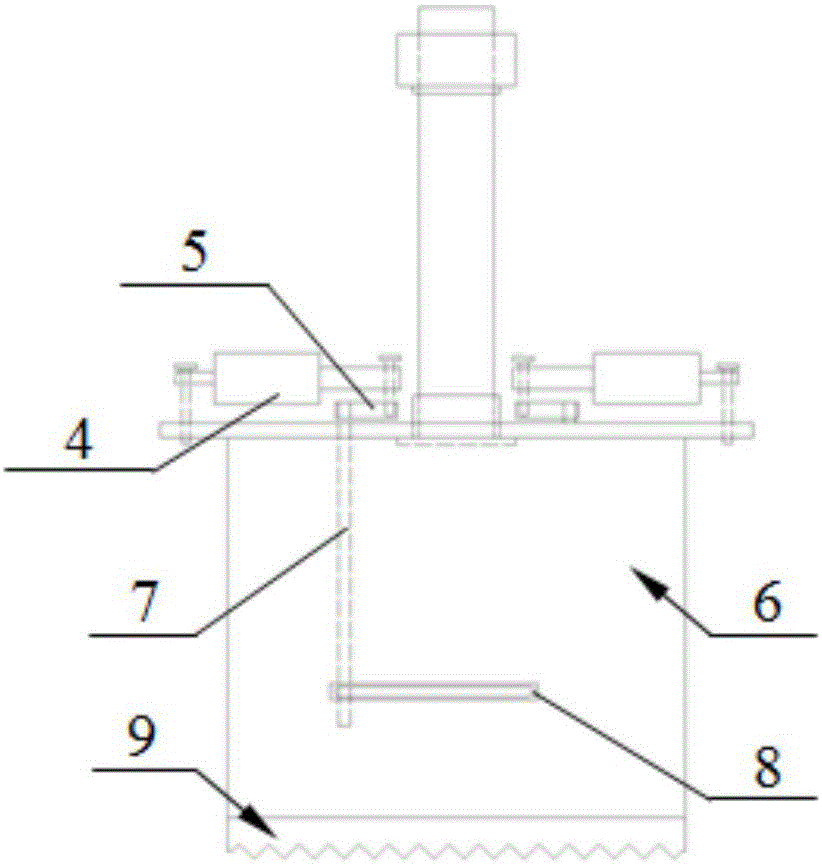

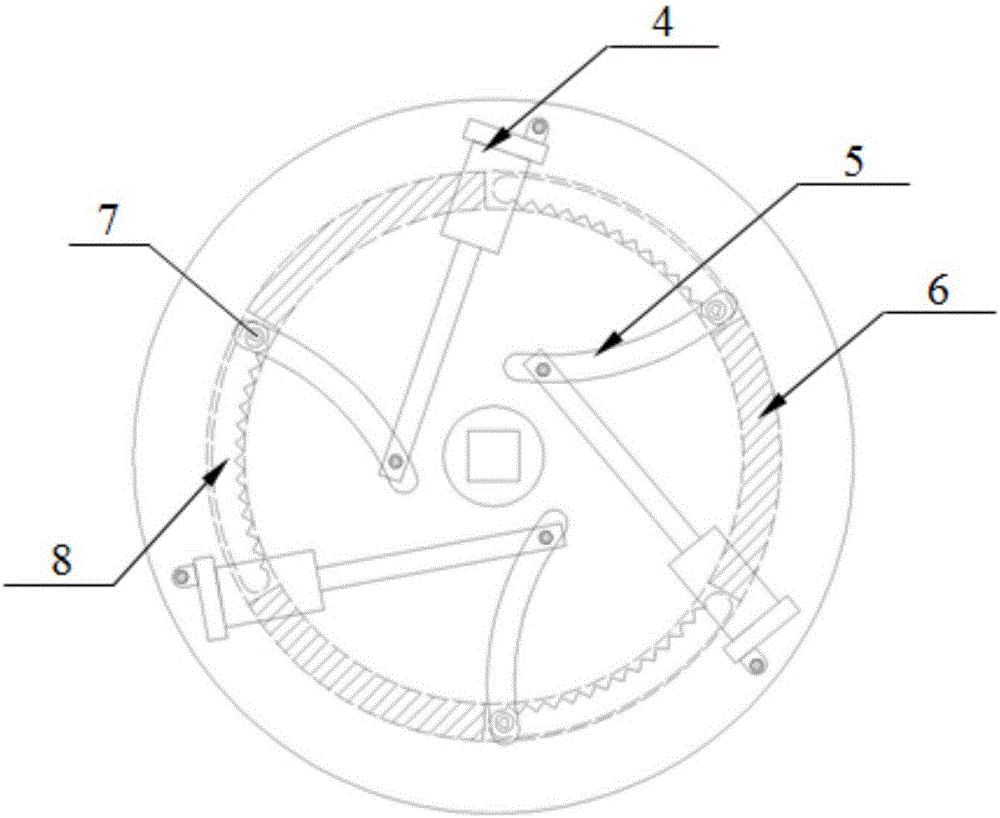

[0023] Such as Figure 1 to Figure 5 As shown, a rotary cutting and coring device for rapidly digging mine pits on hard ground of the present invention includes a power output system, an electric drive system, and an excavation mechanism. The power output system includes a battery 10 and a gasoline engine 1, and an electric drive The system includes a conductive slip ring 3, an electric push-pull rod 4, and an electric lift rod 11. The excavation mechanism includes a sleeve 6 and a cross-cutting blade 8. The sleeve 6 is fixedly connected to a mounting plate on the top of the sleeve 6. There are at least three sets of transverse cutting devices uniformly distributed on the circumference. The transverse cutting device includes a linkage shaft 7 and a cross-cutting blade 8. The linkage shaft 7 is installed in a non-through hole of the cylinder wall. The upper end of the linkage shaft 7 is connected to the dial The rod 5 is fixedly connected, the shift rod 5 is hinged with the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com