Non-disassembling building template assembly

A technology of building templates and templates, which is applied in the direction of building components, buildings, building structures, etc., to achieve the effects of saving construction costs and time, good thermal insulation, and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

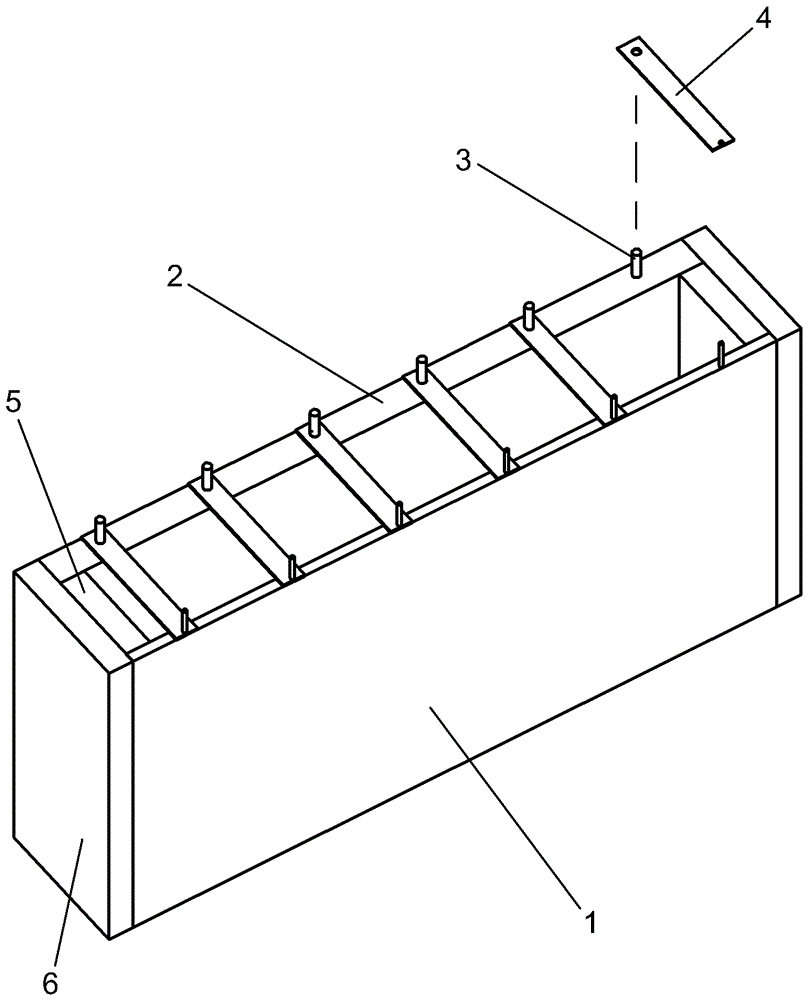

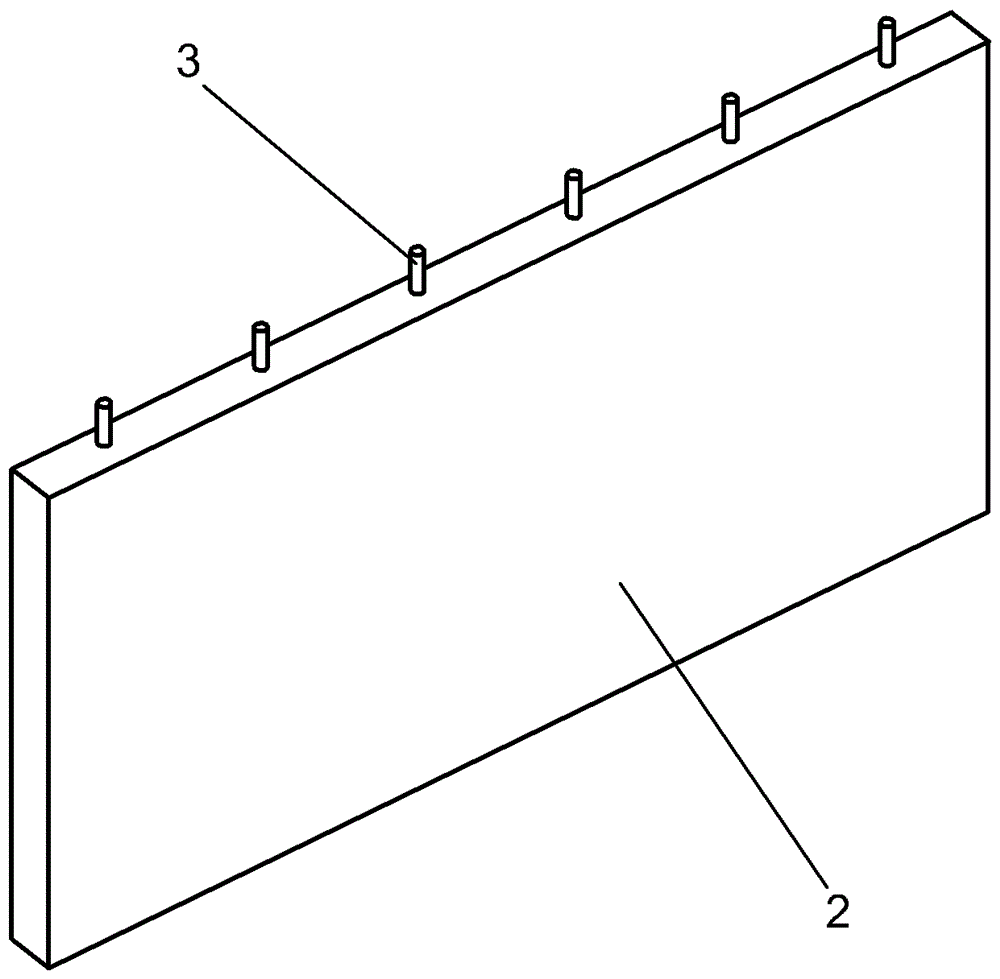

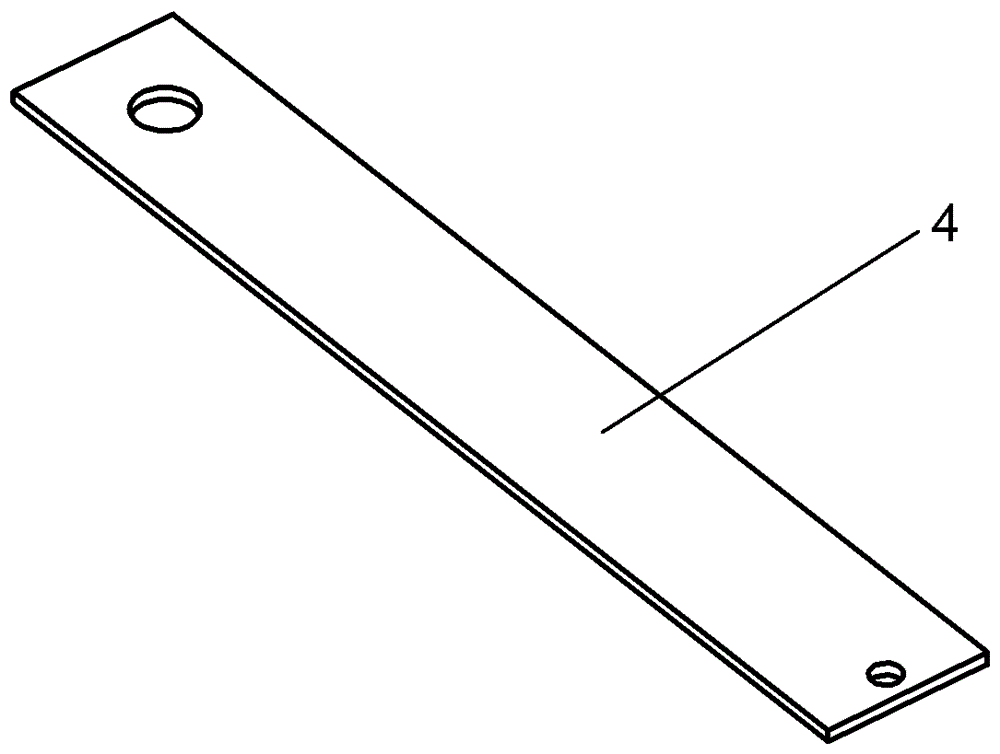

[0020] refer to figure 1 , The building formwork assembly of the present invention includes an inner formwork panel (1), an outer formwork panel (2), a reinforcement bolt (3), a tie bar (4), a limiter (5), and a sealing member (6). Three or more bolt holes are respectively arranged on the upper and lower end surfaces of the inner template panel (1) and the outer template panel (2), and the depth of the latch holes is 1-5 cm. Reinforcing bar bolt (3) is inserted in the latch hole on the inner template panel (1) and the outer template panel (2). The inner formwork panel (1) and the outer formwork panel (2) are relatively placed and connected by tie bars (4). The limiter (5) is in the shape of a cuboid and is placed between the inner formwork panel (1) and the outer formwork panel (2) to limit the distance between the opposite inner formwork panel (1) and the outer formwork panel (2). The sealing piece (6) is in the shape of a cuboid and placed on both ends of the building form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com