Big self-supporting combined steel formwork and firewall construction method thereof

A steel formwork, self-supporting technology, applied in formwork/formwork/work frame, connection parts of formwork/formwork/work frame, on-site preparation of building components, etc. Problems such as construction and template bulging are easy to achieve, achieving the effect of easy assembly and operation, fast construction speed and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

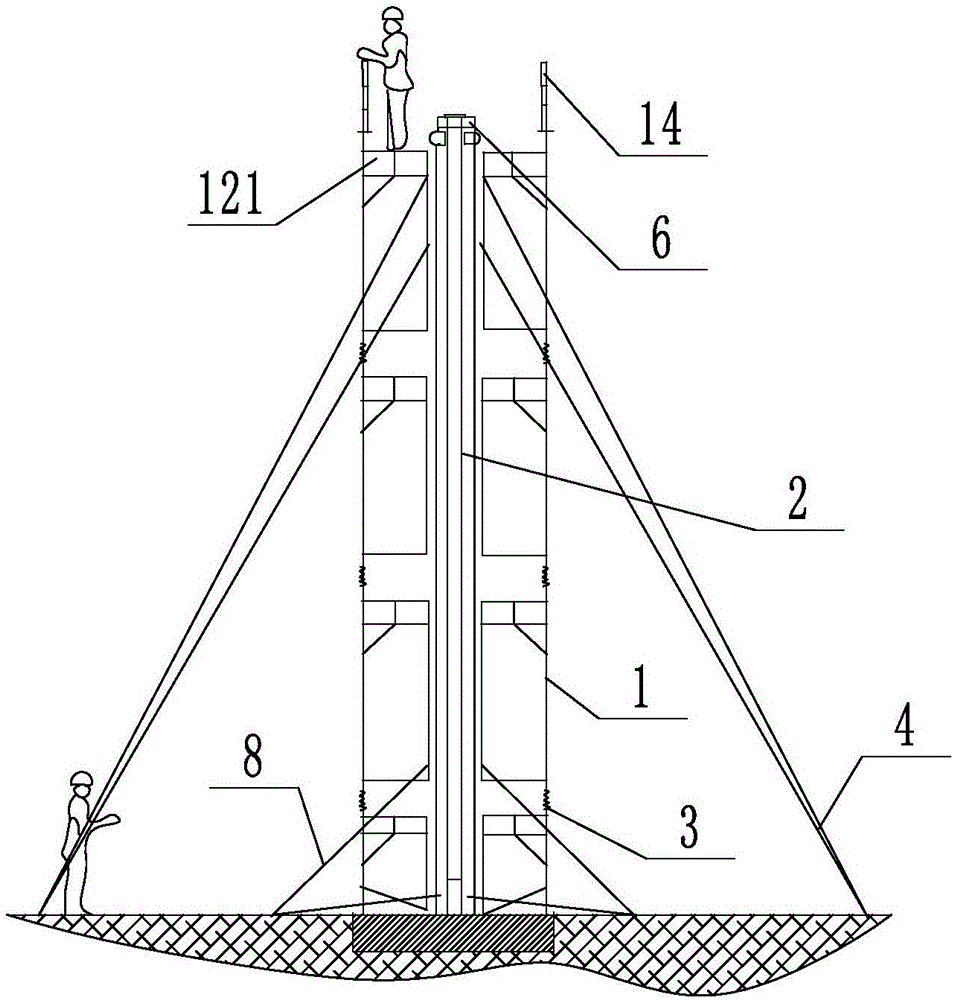

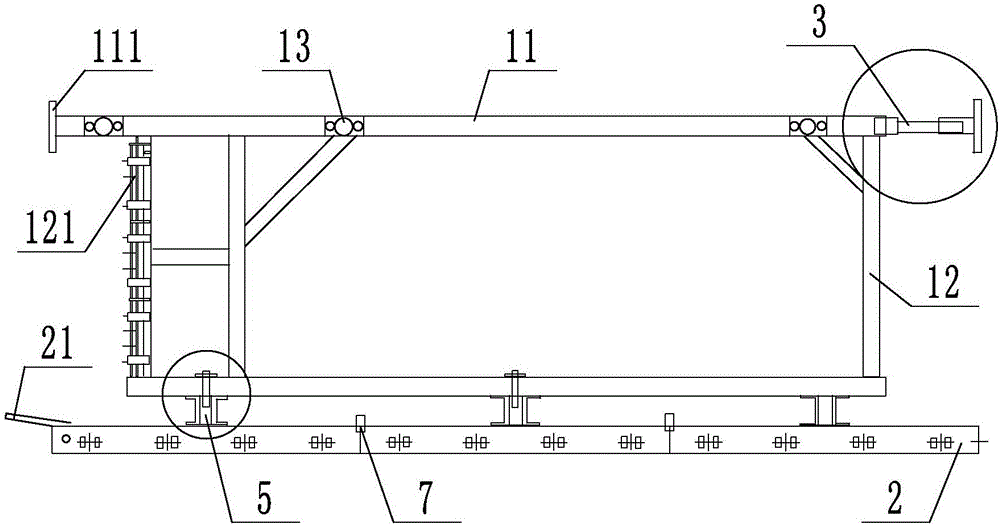

[0057] Such as Figure 1 to Figure 6 As shown, the present invention provides a self-supporting combined large steel formwork, including a supporting door bracket 1, a positive and negative buckle adjustment screw 3 connected between the door brackets 1 and the door Formwork connector 5 for connecting the type support 1 and the building formwork 2.

[0058] Such as figure 2 As shown, the door-type bracket 1 includes at least two door-shaped frame structures composed of two first supports 11 arranged vertically and a plurality of second supports 12 arranged vertically between the first supports 11, The door-shaped frame structures are connected by reinforcing braces 13, such as figure 2 As shown, the reinforcing brace 13 is provided with a plate with holes, which is connected and fixed with the first support 11 by bolts, and an operating platform 121 is provided on the second support 12 at the top of each section of the door bracket 1.

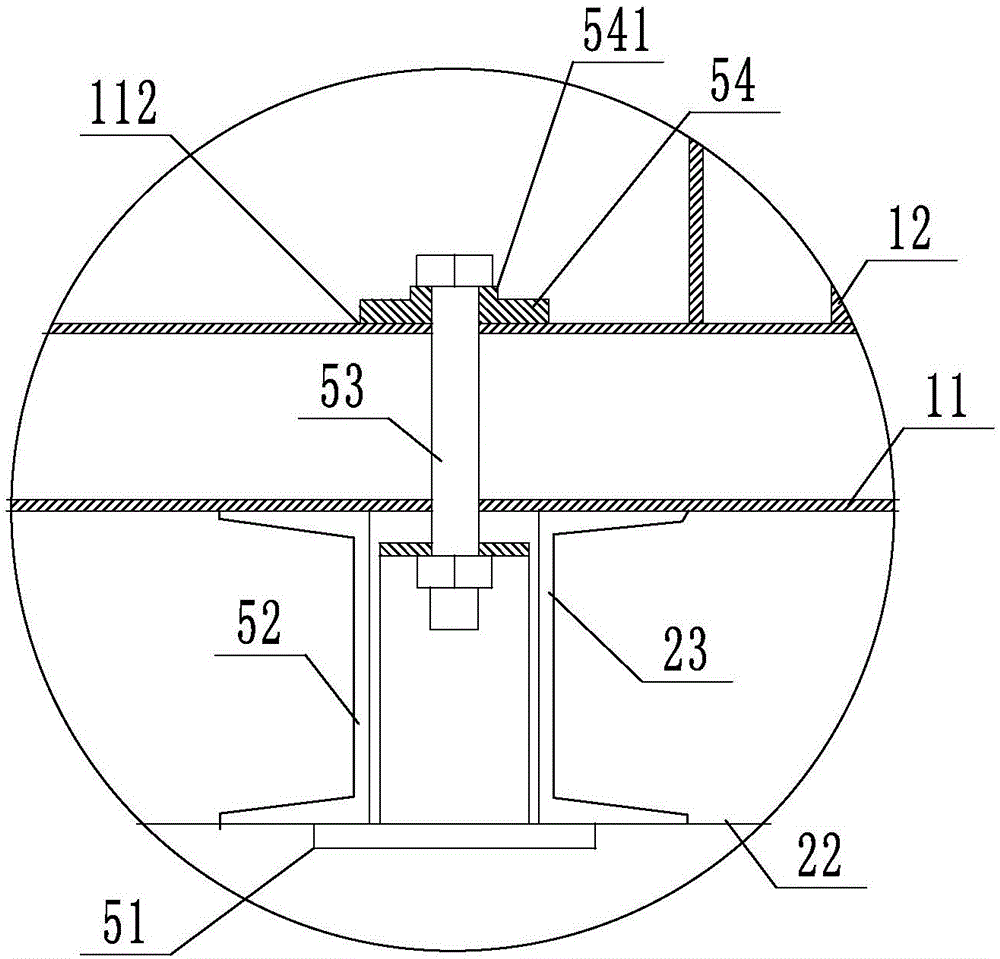

[0059] Such as Figure 5 with Image 6 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com