Setting method of thick loose water-bearing layer sand prevention safe coal and rock pillar under water pressure effect

A thick loose, hydraulic technology, applied in earth-moving drilling, underground mining, surface mining and other directions, can solve the problems of sand burst accident, can not fully adapt to the requirements of thick loose layer sand control safety coal and rock pillar retention requirements, increase and other problems, achieve The effect of reducing the probability of sand breaking accidents, conducive to safe production and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

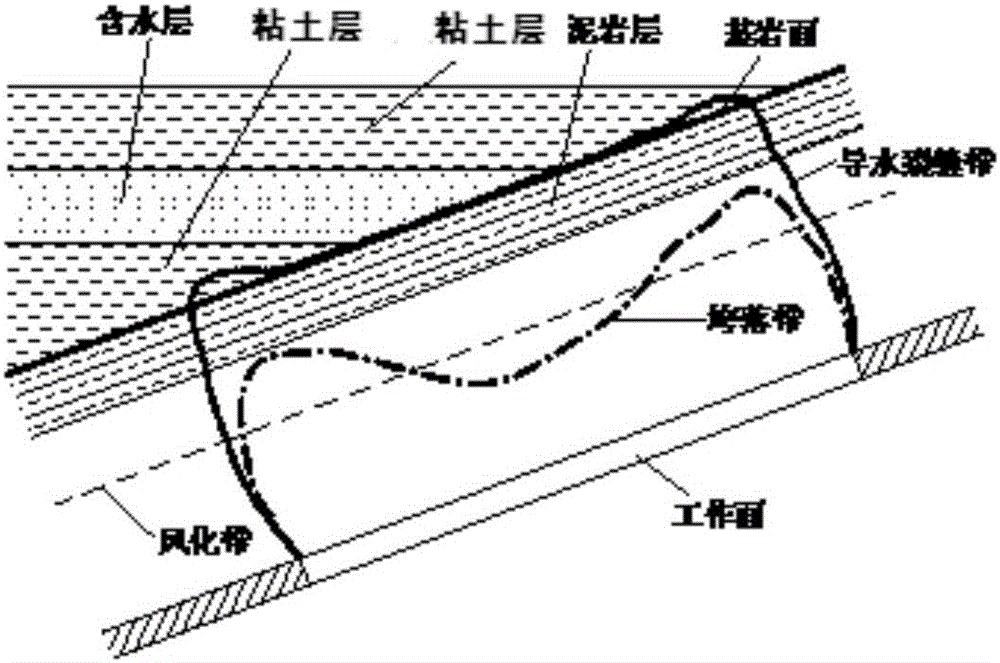

[0043] The method of the present invention is suitable for image 3 The geological conditions shown for a thick unconsolidated aquifer in a wedge-shaped seal structure overlying a coal seam to be mined.

[0044] Among them, the geological condition of the thick unconsolidated aquifer overlying the wedge-shaped sealing structure refers to the formation of the upper and lower thick clay layers and the basement rock weathering zone on the working face such as image 3 The wedge seal configuration shown. If the upper and lower thick clay layers of the aquifer and the rocks in the bedrock weathered zone have good water barrier performance, the aquifer can maintain a high water pressure under sealed conditions, and the mining of the adjacent working face cannot reduce the water level of the aquifer .

[0045]In the prior art, in the case of image 3 When mining under the geological conditions of the thick unconsolidated aquifer shown, the setting of the thickness of the sand cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com