Automatic powder discharging water jet capable of realizing one-way filtering and high-low pressure water flow conversion

A one-way filtering and automatic conversion technology, applied in hydraulic mining, earth drilling, special mining, etc., can solve the problems of increased labor intensity of workers, impact on underground production efficiency, low drilling efficiency, etc., to solve the difficulty of dismantling, The effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments. This embodiment provides detailed implementation methods and specific operation processes on the premise of the technical solution of the present invention.

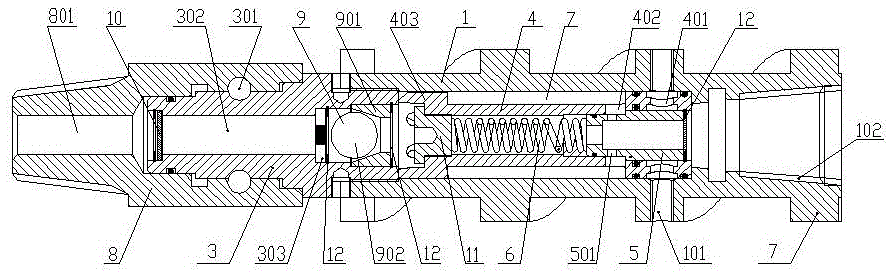

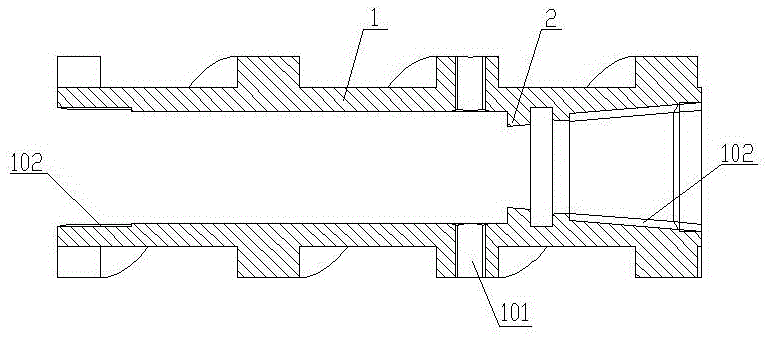

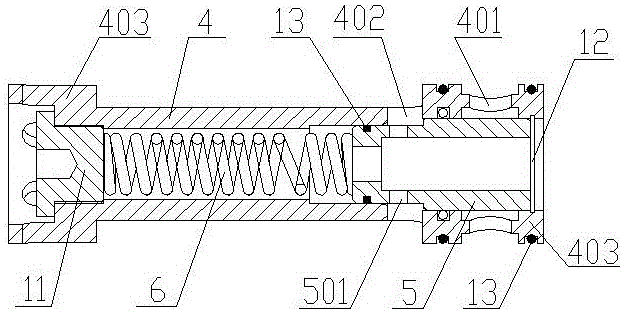

[0026] As shown in the figure, the present invention is a self-draining powder-type one-way filtering high and low pressure water flow automatic conversion water jet, including a rod body 1 with an auger on the outer wall and a drill bit 8 connected to the rod body 1. The rod body 1 has a water supply The central channel for the flow of water, the tail end of the rod body 1 along the punching direction is provided with a plurality of jet nozzles 101 that penetrate the side wall of the rod body 1 and are placed in the central channel, and the two ends of the rod body 1 are provided with female joints 102, and the tail of the central channel is connected to the central channel. An annular limit protrusion 2 is arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com