Tunnel lining trolley, working method and installation method of pre-grouting pipe fixing device

A technology for lining trolleys and pre-grouting pipes, applied in tunnel lining, tunnel, shaft lining, etc., can solve problems such as easy loosening, and achieve the effect of strengthening the fixed connection relationship, maintaining stability, and reliable fixing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

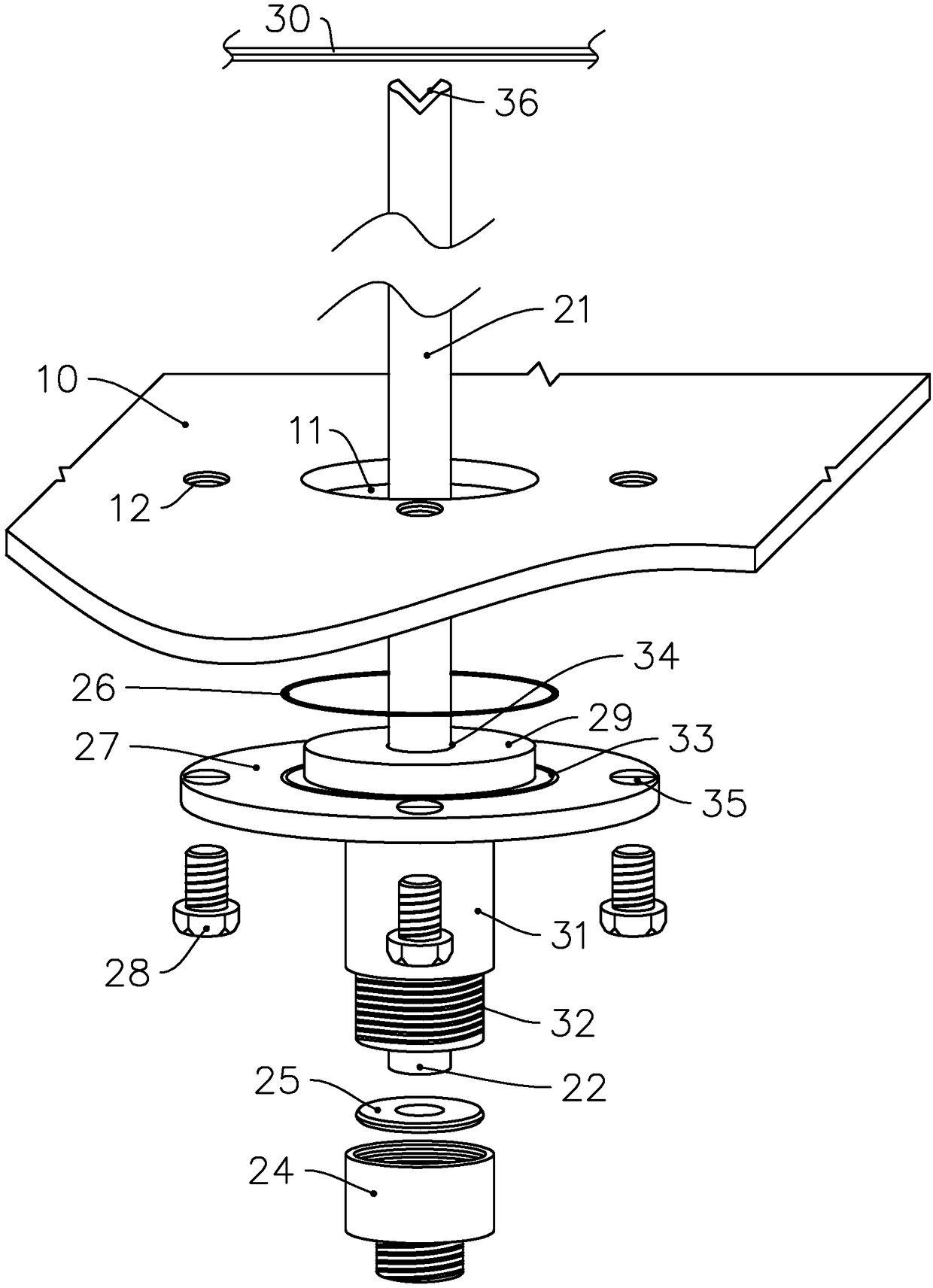

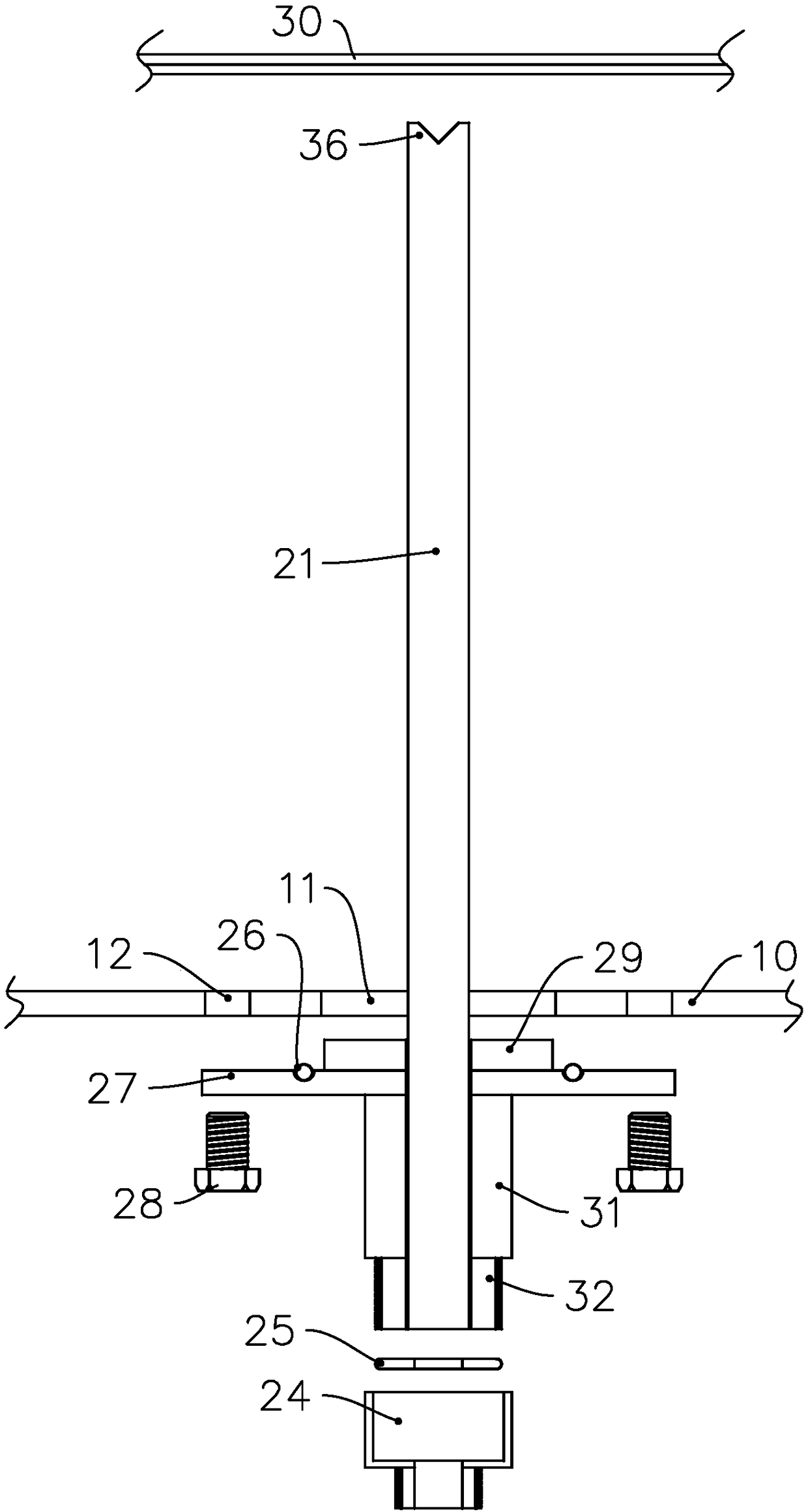

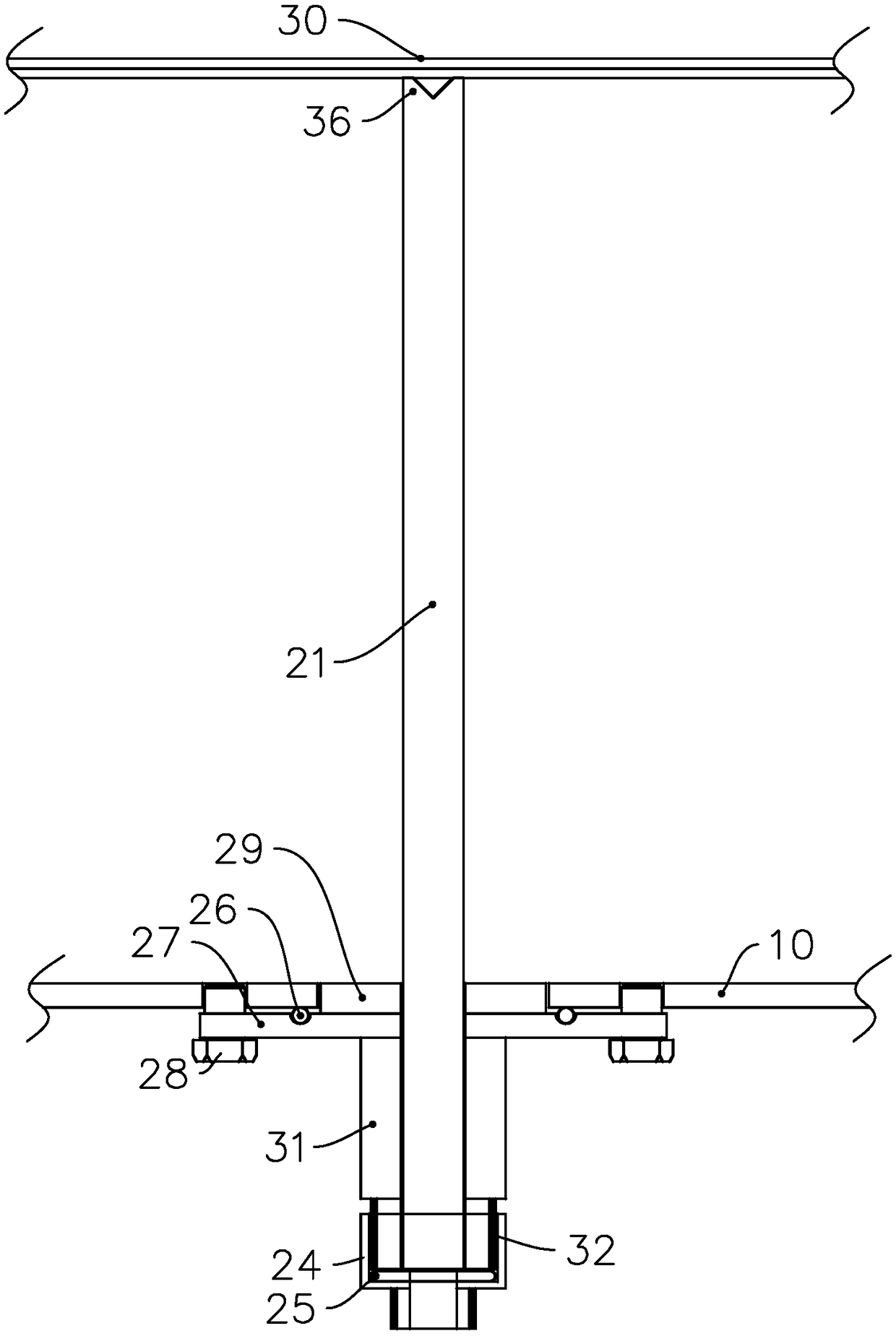

[0028] Such as figure 1 with figure 2 As shown, the lining trolley of this embodiment has a trolley template 10 and a fixing device. The lining trolley is in the tunnel, and the tunnel has primary support 30 .

[0029] The trolley template 10 has a first through hole 11 , the cross section of which is circular, and the function of the first through hole is for the pre-grouting pipe 21 to collide with the primary support 30 of the tunnel after passing through.

[0030] The fixing device includes a pre-grouting pipe 21 , a connecting unit, a grouting pipe, a connecting pipe piece 24 and a second sealing ring 25 .

[0031] The connection unit has a first sealing ring 26 and a connection disc 27 .

[0032] The connecting plate 27 is a cylindrical connecting plate, and the connecting plate 27 can be fixed on the trolley formwork 10 by fasteners 28. There are four second threaded holes 12 on the trolley formwork 10, and the fasteners 28 can be specifically fastened with bolts. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com