A fuel injection system component of an aerospace engine and a fuel injection method thereof

A technology of aerospace and fuel injection systems, which is applied to engine components, machines/engines, turbines/propellant fuel delivery systems, etc. It can solve the problems of insufficient power, poor fuel atomization effect, and failure to return oil to achieve strong output power , fully mixed and fully fueled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

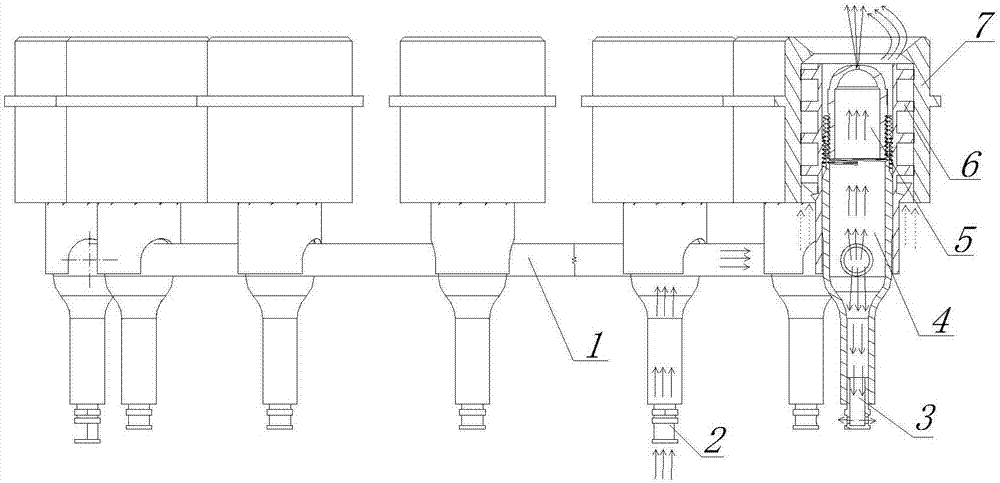

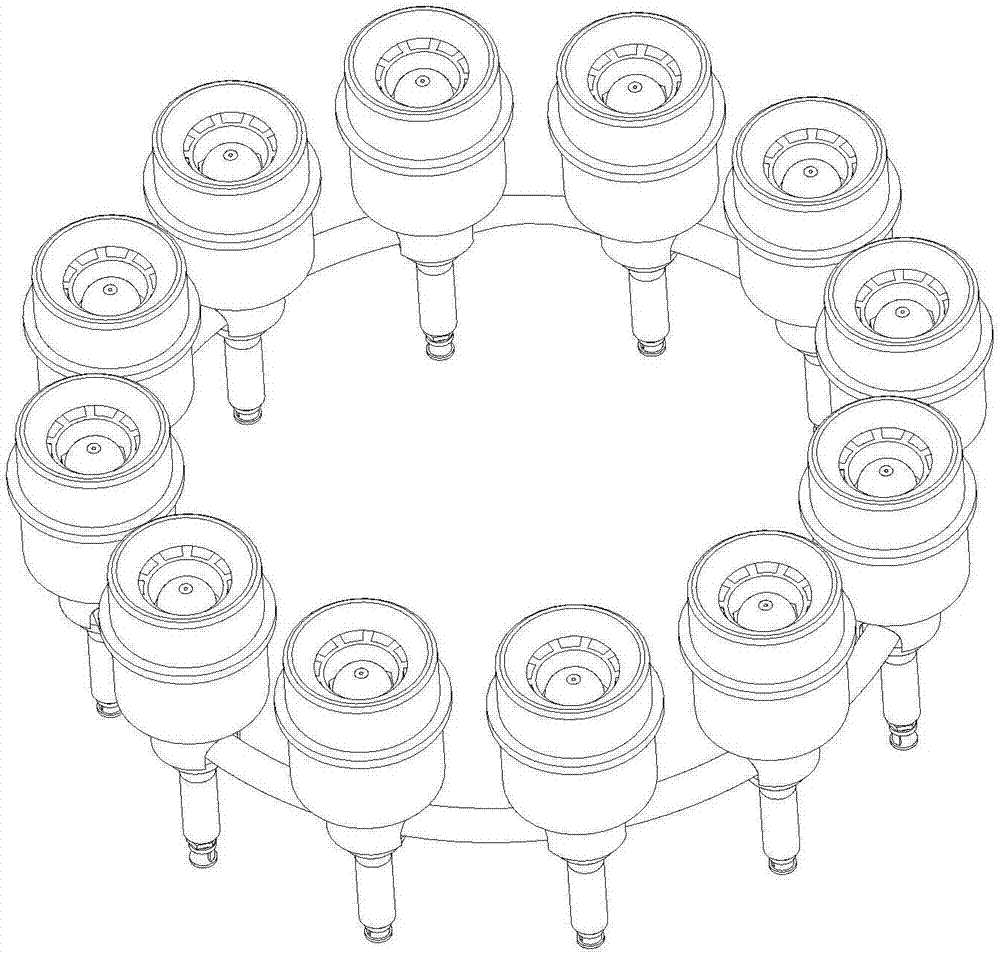

[0025] See figure 1 and figure 2 , the present invention comprises a plurality of bottle-shaped main pipe bodies 4 and multi-section arc-shaped pipe bodies 1, and each bottle-shaped main pipe body 4 communicates with each other through the arc-shaped pipe bodies 1 to form a ring-shaped whole; the upper end of the bottle-shaped main pipe body 4 is installed There is a fuel injection nozzle 5, and an air intake guide vane fan 6 is arranged outside the fuel injection nozzle 5, and an outer cover body 7 is arranged outside the air intake guide vane fan 6; the lower ends of each bottle-shaped main body 4 are respectively installed with pressure relief valves at intervals. Oil nozzle 3 and oil inlet nozzle 2.

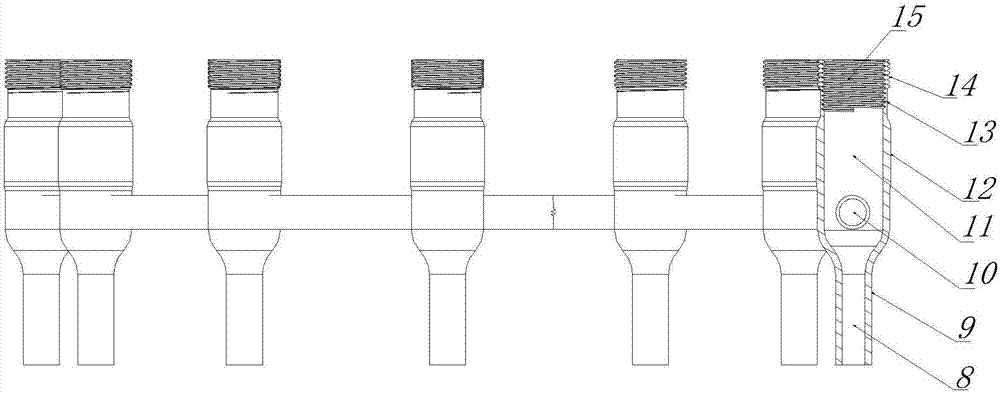

[0026] See image 3 , the bottle-shaped main body 4 is an upside-down, wine bottle-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com