Novel connecting structure of thin-wall stainless steel pipe and pipe joint

A technology of stainless steel pipe and connection structure, applied in the direction of pipe/pipe joint/pipe fitting, sealing surface connection, passing element, etc., can solve the problems of high processing cost, loose connection, complex structure, etc., to achieve good sealing, good connection effect, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

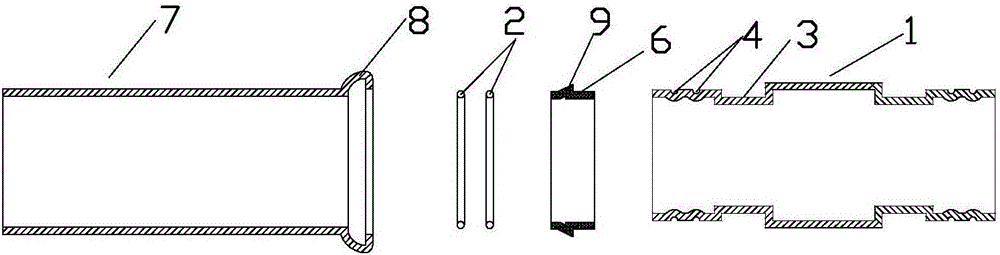

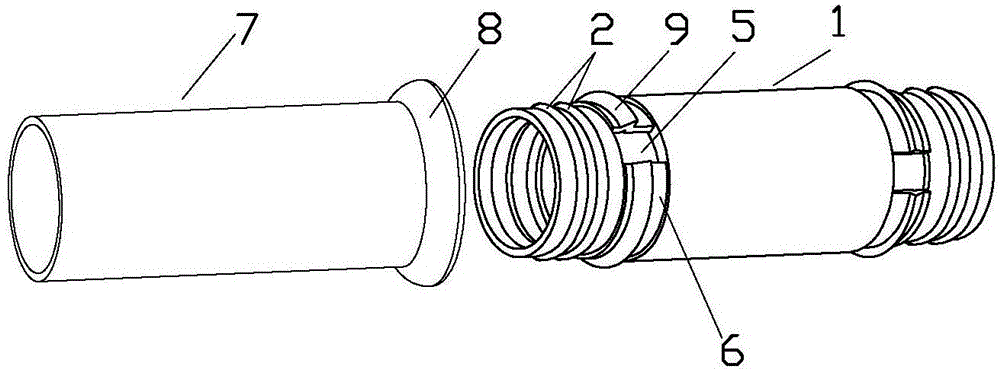

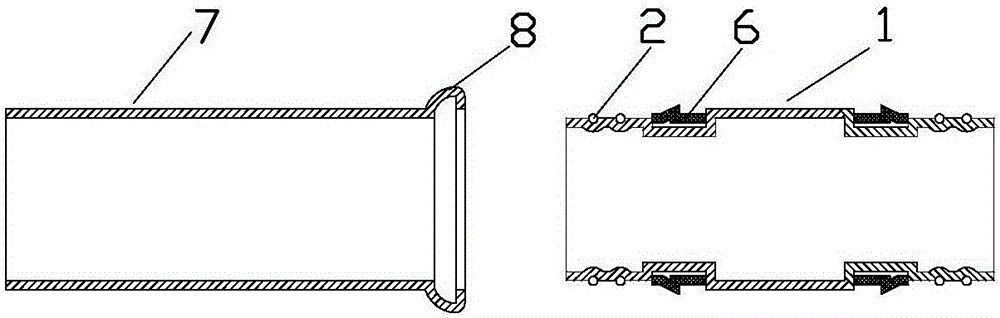

[0014] see figure 1 - Figure 4 , to provide a new connection structure between a thin-walled stainless steel pipe 7 and a pipe joint 1. The diameter of the connecting end of the pipe joint 1 is reduced, and its outer wall is provided with two sealing rings 2 and a circular ring in the axial direction from the pipe mouth. Buckle groove 3, each sealing ring 2 is respectively covered on each sealing ring groove 4 provided on the outer wall, and the buckle groove 3 is covered with a ring-shaped buckle 6 with a notch 5, which can act on the notch 5 through a special tool, Put buckle 6 on or remove buckle slot 3. The connecting end port of the stainless steel pipe 7 forms a ring-type clamping position 8 through flaring.

[0015] Specifically, the outer wall of the buckle 6 is provided with an annular rib 9 with a bevel, and the rear side of the rib 9 is close to the inner edge of the ring mouth of the ring-shaped locking position 8, so that the gap between the buckle 6 and the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com