M-shaped sealing method of vacuum insulated panel

A technology of vacuum insulation panel and packaging method, which is applied to heat exchange equipment, protects pipes through thermal insulation, material gluing, etc., can solve the problems of inability to install vacuum insulation panels and inability to achieve thermal insulation effect, and achieves simple production and good thermal insulation effect. , Reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

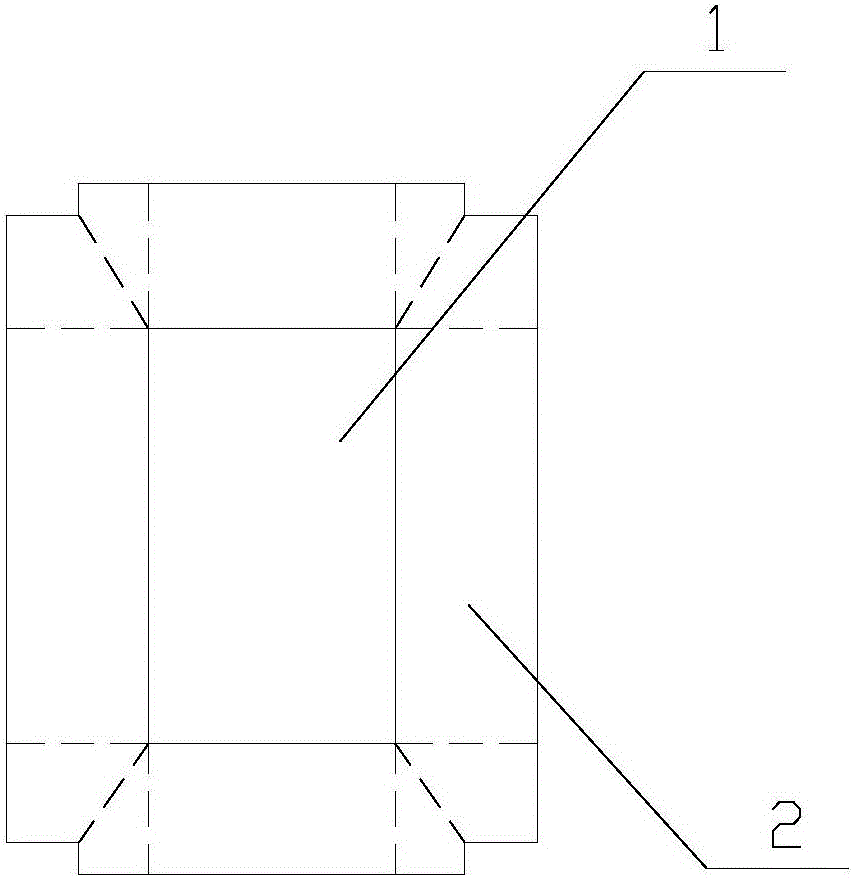

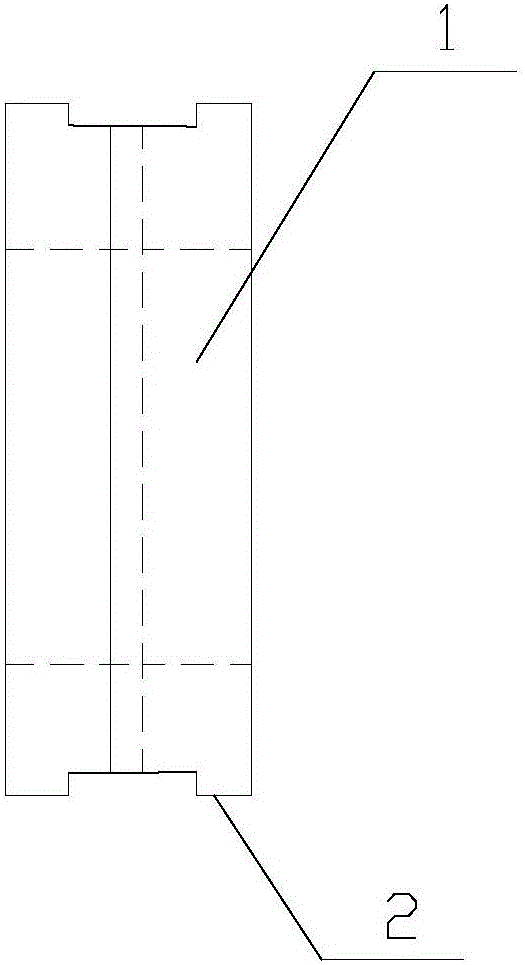

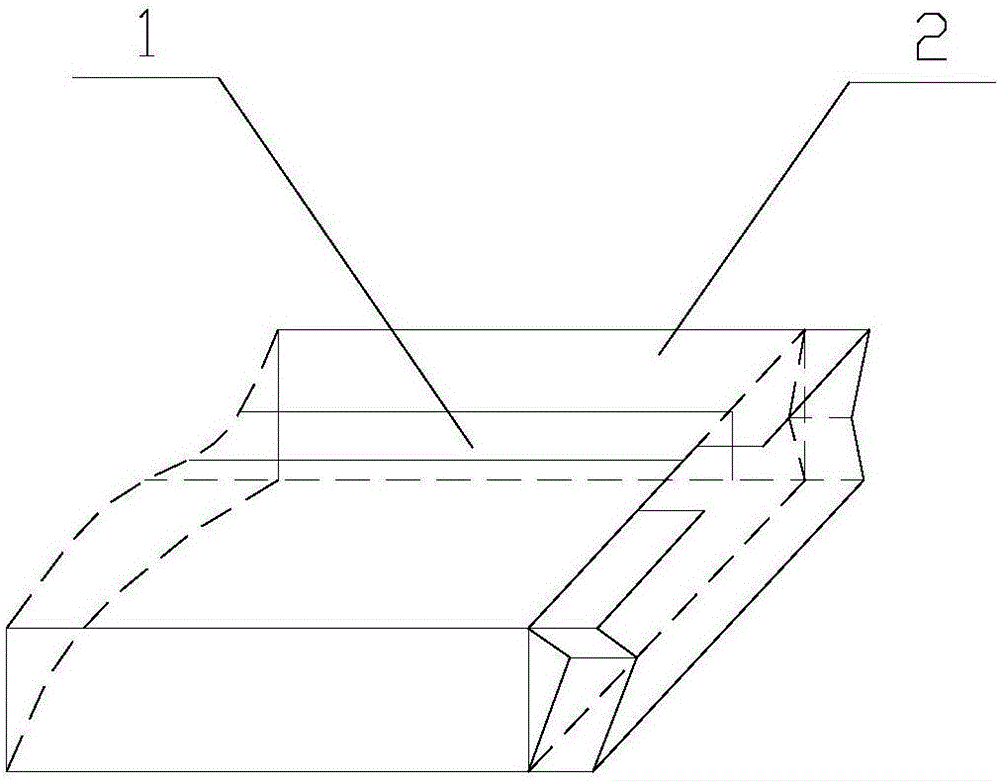

[0019] Such as Figure 1-Figure 6 As shown, this specific embodiment adopts the following technical scheme: its packaging method includes the following steps: a. First place the vacuum insulation panel 1 in the middle of the barrier film 2, and the two sides of the barrier film 2 are along the sides of the vacuum insulation panel 1. The two sides are folded toward the middle position of the upper surface of the vacuum insulation panel 1 at the same time to form a rectangular structure (such as figure 1 and figure 2 shown); b, then fold the openings at both ends of the rectangular structure inwardly to form an inner triangular structure, and glue the adjacent two sides of the inner triangular structure (such as image 3 and Figure 4 shown); c, the two ends of the glued rectangular structure are folded and wrapped in the middle of the rectangular structure at the same time, and the production is completed (such as Figure 5 and Figure 6 shown).

[0020] Wherein, the barr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com