A liquid carbon dioxide filling system

A liquid carbon dioxide, filling system technology, applied in gas/liquid distribution and storage, fluid processing, equipment loaded into pressure vessels, etc. To prevent coal and gas outburst, increase coal seam extraction rate, and reduce coal seam internal energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

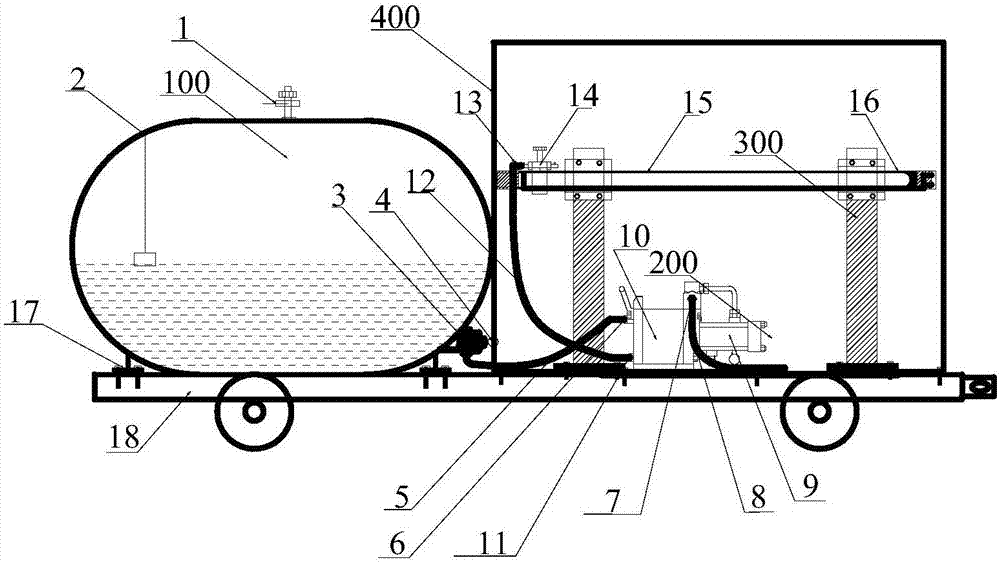

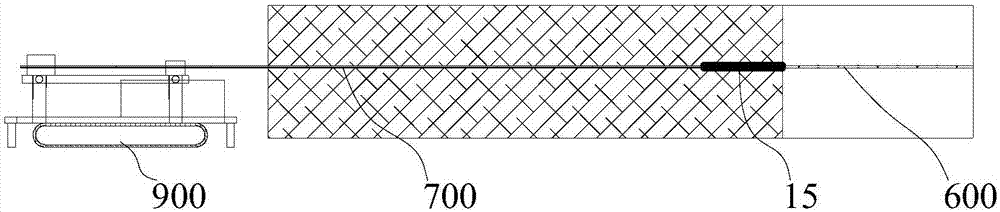

[0036] Such as figure 1 As shown, a carbon dioxide filling system includes a flatbed car 18 on which a liquid carbon dioxide storage tank 100 and a push rod box 400 are fixed by fastening screws 17 .

[0037] The liquid storage tank 100 includes a liquid injection port 1 and a liquid outlet port 3 , a liquid level gauge 2 is arranged in the liquid storage tank 100 , and a first pressure gauge 4 is arranged at the liquid outlet port 3 .

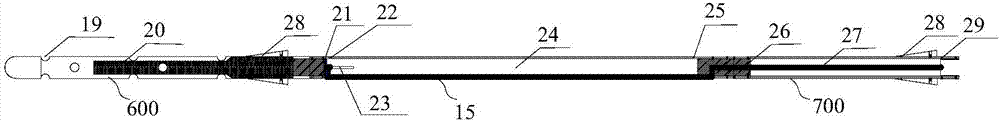

[0038] Push rod box 400 The push rod 700 of the carbon dioxide phase change fracturing device, the release pipe 600 and the liquid storage pipe 15 are placed in the push rod box. The outside of the push rod box 400 is fixed with a carbon dioxide booster pump 200 and two oppositely arranged The liquid storage tube filling frame 300, the liquid storage tube 15 can be installed on the carbon dioxide liquid storage tube filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com